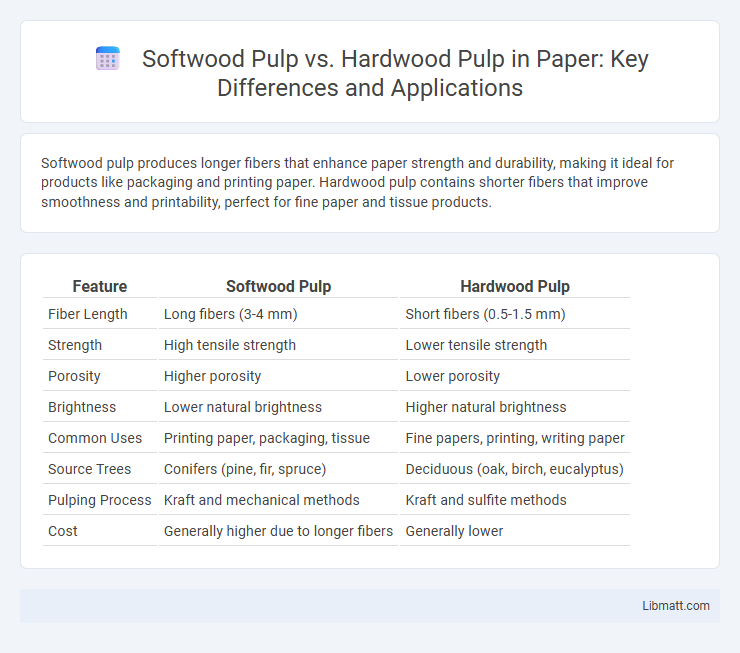

Softwood pulp produces longer fibers that enhance paper strength and durability, making it ideal for products like packaging and printing paper. Hardwood pulp contains shorter fibers that improve smoothness and printability, perfect for fine paper and tissue products.

Table of Comparison

| Feature | Softwood Pulp | Hardwood Pulp |

|---|---|---|

| Fiber Length | Long fibers (3-4 mm) | Short fibers (0.5-1.5 mm) |

| Strength | High tensile strength | Lower tensile strength |

| Porosity | Higher porosity | Lower porosity |

| Brightness | Lower natural brightness | Higher natural brightness |

| Common Uses | Printing paper, packaging, tissue | Fine papers, printing, writing paper |

| Source Trees | Conifers (pine, fir, spruce) | Deciduous (oak, birch, eucalyptus) |

| Pulping Process | Kraft and mechanical methods | Kraft and sulfite methods |

| Cost | Generally higher due to longer fibers | Generally lower |

Introduction to Softwood and Hardwood Pulp

Softwood pulp, derived from coniferous trees such as pine and spruce, contains longer fibers that provide superior strength and durability in paper products. Hardwood pulp, sourced from deciduous trees like birch and eucalyptus, has shorter fibers that contribute to smoother texture and higher printability in finished paper. Understanding these differences helps you choose the right pulp type based on the desired paper quality and application.

Botanical Origins and Sources

Softwood pulp originates from coniferous trees such as pine, spruce, and fir, known for their longer fibers that provide strength and durability in paper products. Hardwood pulp is derived from deciduous trees like eucalyptus, birch, and maple, characterized by shorter fibers that enhance smoothness and print quality. Understanding the botanical origins helps you choose the right pulp type for specific paper manufacturing needs, balancing strength and surface texture.

Fiber Structure and Composition

Softwood pulp features longer fibers, typically 2-4 mm, composed mainly of cellulose with lower lignin content, providing strength and durability ideal for paper products requiring toughness. Hardwood pulp contains shorter fibers, around 0.5-1 mm, with higher hemicellulose and lignin proportions, resulting in a smoother texture and better printability. Your choice between softwood and hardwood pulp impacts paper quality by balancing strength and surface smoothness based on fiber structure and chemical composition.

Key Differences in Chemical Properties

Softwood pulp contains longer cellulose fibers, resulting in higher tensile strength and durability, while hardwood pulp has shorter fibers that provide smoothness and density. Chemically, softwood pulp has higher lignin content, requiring stronger bleaching processes, whereas hardwood pulp contains more hemicellulose, influencing its reactivity and bonding characteristics. These chemical differences directly impact pulp processing methods and the quality of paper products produced.

Pulping Processes for Each Type

Softwood pulp is typically produced through mechanical or chemical pulping processes such as the kraft method, which preserves longer fibers and enhances strength for products like paper and packaging. Hardwood pulp commonly undergoes chemical pulping methods like sulfite or kraft pulping, breaking down shorter fibers to create smooth, fine paper surfaces ideal for printing and writing papers. Understanding the differences in pulping processes helps optimize your paper production for specific uses, balancing strength and texture requirements.

Strength and Quality Characteristics

Softwood pulp fibers are longer and stronger, providing superior tensile strength and tear resistance ideal for producing durable paper products. Hardwood pulp fibers are shorter and finer, contributing to smoother surface quality and better printability but lower strength compared to softwood pulp. Combining both pulps enhances overall paper performance by balancing strength and quality characteristics.

Applications in Paper Manufacturing

Softwood pulp, known for its longer fibers, provides superior strength and durability, making it ideal for high-quality paper products such as packaging, printing, and writing papers. Hardwood pulp, composed of shorter fibers, offers smoothness and a finer texture, suitable for producing newspapers, tissue papers, and coated papers. Your choice between softwood and hardwood pulp impacts the paper's strength, texture, and end-use application in the manufacturing process.

Environmental Impact and Sustainability

Softwood pulp, derived from coniferous trees, generally has a longer fiber length, contributing to stronger paper products and often requires less chemical processing, which can reduce environmental impact compared to hardwood pulp from deciduous trees. Hardwood pulp fibers are shorter, producing smoother paper but may necessitate more intensive bleaching and chemical treatments, increasing resource use and emissions. Sustainable forestry practices, certification programs like FSC or PEFC, and advancements in pulp processing technology significantly influence the environmental footprint of both softwood and hardwood pulps.

Cost Factors and Market Trends

Softwood pulp generally incurs higher production costs due to longer fiber processing times and greater energy consumption, while hardwood pulp benefits from faster processing and lower raw material expenses, making it more cost-effective for many applications. Market trends indicate growing demand for hardwood pulp in packaging and tissue products driven by sustainability concerns and renewable resources, whereas softwood pulp remains preferred in high-strength paper products due to its longer fiber length. Your choice between softwood and hardwood pulp will depend on balancing cost considerations with the required paper qualities and evolving market demands.

Choosing the Right Pulp for Your Needs

Softwood pulp offers longer fibers that provide superior strength and durability, making it ideal for products requiring toughness and resilience such as packaging and textiles. Hardwood pulp contains shorter fibers that yield smoother, finer paper surfaces, suited for printing, writing papers, and tissue products. Selecting the right pulp depends on balancing the need for strength with surface quality based on the intended application.

Softwood pulp vs hardwood pulp Infographic

libmatt.com

libmatt.com