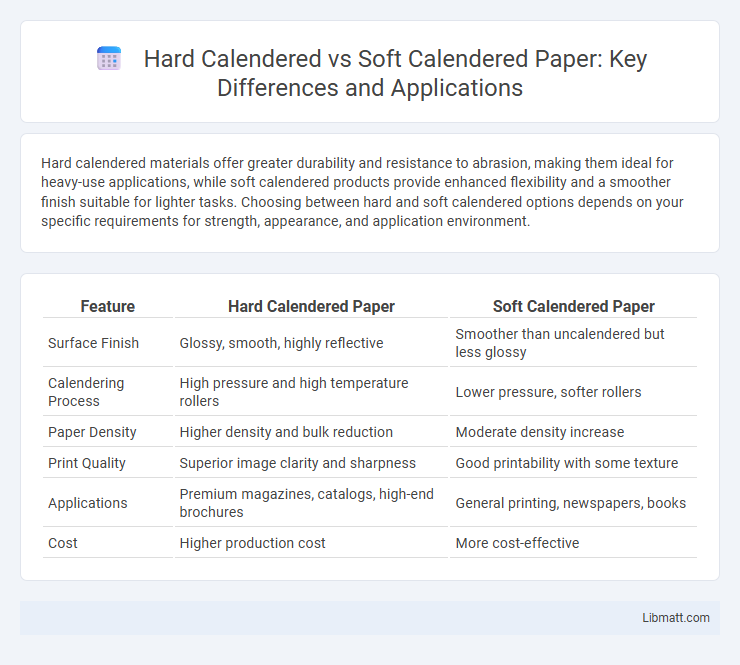

Hard calendered materials offer greater durability and resistance to abrasion, making them ideal for heavy-use applications, while soft calendered products provide enhanced flexibility and a smoother finish suitable for lighter tasks. Choosing between hard and soft calendered options depends on your specific requirements for strength, appearance, and application environment.

Table of Comparison

| Feature | Hard Calendered Paper | Soft Calendered Paper |

|---|---|---|

| Surface Finish | Glossy, smooth, highly reflective | Smoother than uncalendered but less glossy |

| Calendering Process | High pressure and high temperature rollers | Lower pressure, softer rollers |

| Paper Density | Higher density and bulk reduction | Moderate density increase |

| Print Quality | Superior image clarity and sharpness | Good printability with some texture |

| Applications | Premium magazines, catalogs, high-end brochures | General printing, newspapers, books |

| Cost | Higher production cost | More cost-effective |

Introduction to Calendering in Material Processing

Calendering in material processing involves passing materials like paper, textiles, or plastics through rollers to achieve desired thickness, surface finish, and gloss. Hard calendered materials use polished steel rollers to create a smooth, glossy, and dense surface, enhancing durability and aesthetic appeal. Soft calendered processes employ softer rollers, often coated with rubber, producing a matte finish with improved texture and flexibility, allowing you to tailor the product to specific performance requirements.

What is Hard Calendering?

Hard calendering is a process where fabric or paper passes through heated rollers under high pressure, resulting in a smooth, glossy, and dense surface finish. This technique enhances the material's durability, strength, and surface uniformity by compressing fibers tightly and allowing better ink adhesion or coating application. Commonly used in textiles, plastics, and paper industries, hard calendered products exhibit superior sheen and dimensional stability compared to soft calendered counterparts.

What is Soft Calendering?

Soft calendering is a textile finishing process where fabric passes through a series of rollers at lower temperatures and pressures, enhancing smoothness and softness without compromising fabric strength. This method retains fabric flexibility, making it ideal for delicate materials like knits and synthetic blends. Your choice of soft calendered fabrics ensures a comfortable feel and improved aesthetic appeal, particularly in apparel and home textiles.

Key Differences Between Hard and Soft Calendering

Hard calendering uses heated rollers to apply high pressure and heat, producing smooth, glossy surfaces ideal for synthetic materials and vinyl films. Soft calendering employs lower pressure and unheated, softer rollers, resulting in textured, matte finishes suited for fabrics and delicate materials. Your choice between hard and soft calendering depends on the desired surface finish, texture, and material type.

Applications of Hard Calendered Materials

Hard calendered materials are commonly used in applications requiring high durability and gloss, such as automotive wraps, packaging films, and graphic displays. Their enhanced surface finish and resistance to scratches make them ideal for outdoor signage and vehicle graphics. You benefit from their superior toughness and vibrant appearance in projects demanding long-lasting visual impact.

Applications of Soft Calendered Materials

Soft calendered materials are widely used in applications requiring flexibility and enhanced surface finish, such as synthetic leather for upholstery, automotive interiors, and footwear. Their ability to produce smooth, glossy, and stretchable surfaces makes them ideal for garments and fashion accessories. Your projects benefit from the superior softness and durability provided by soft calendered materials in these industries.

Advantages of Hard Calendered Products

Hard calendered products offer superior durability and scratch resistance compared to soft calendered alternatives, making them ideal for heavy-traffic applications. Their enhanced surface finish provides better optical clarity and color vibrancy, which is essential for high-quality printing and signage. These properties result in longer-lasting materials with reduced maintenance costs and improved aesthetic appeal.

Benefits of Soft Calendered Products

Soft calendered products offer superior flexibility and enhanced surface smoothness, making them ideal for applications requiring high optical clarity and gloss. Their lower processing temperature preserves material integrity, resulting in better mechanical properties and resistance to cracking. You benefit from improved printability and adhesion, which ensures high-quality finishes in packaging, laminates, and synthetic leather production.

Choosing the Right Calendering Method

Choosing the right calendering method depends on the desired finish and material flexibility; hard calendered films offer a glossy, durable surface ideal for applications requiring high clarity and abrasion resistance, while soft calendered films provide a matte, softer feel suitable for flexible packaging and labels. Hard calendering employs steel rolls heated to high temperatures, resulting in tighter polymer orientation and superior dimensional stability. Soft calendered processes use softer rolls and lower temperatures, allowing better conformability and wrinkle resistance for complex shapes.

Future Trends in Calendered Materials

Future trends in calendered materials emphasize the development of environmentally sustainable processes and advanced polymer formulations to enhance durability and flexibility. Innovations in nanotechnology integration and precision control of nip pressure and temperature are expected to improve material consistency and surface finish. The industry is moving towards energy-efficient calendering techniques coupled with real-time monitoring systems to optimize product quality and reduce waste.

hard calendered vs soft calendered Infographic

libmatt.com

libmatt.com