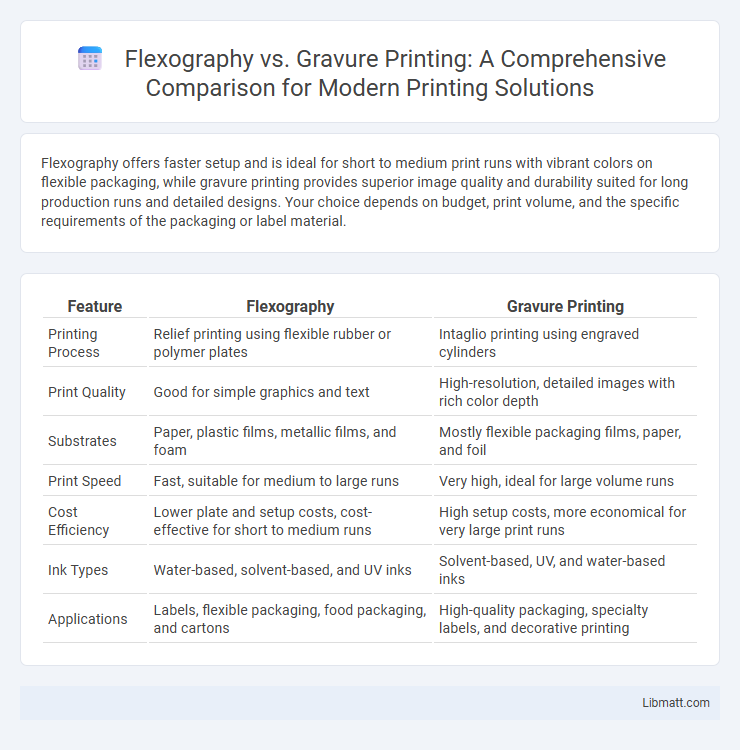

Flexography offers faster setup and is ideal for short to medium print runs with vibrant colors on flexible packaging, while gravure printing provides superior image quality and durability suited for long production runs and detailed designs. Your choice depends on budget, print volume, and the specific requirements of the packaging or label material.

Table of Comparison

| Feature | Flexography | Gravure Printing |

|---|---|---|

| Printing Process | Relief printing using flexible rubber or polymer plates | Intaglio printing using engraved cylinders |

| Print Quality | Good for simple graphics and text | High-resolution, detailed images with rich color depth |

| Substrates | Paper, plastic films, metallic films, and foam | Mostly flexible packaging films, paper, and foil |

| Print Speed | Fast, suitable for medium to large runs | Very high, ideal for large volume runs |

| Cost Efficiency | Lower plate and setup costs, cost-effective for short to medium runs | High setup costs, more economical for very large print runs |

| Ink Types | Water-based, solvent-based, and UV inks | Solvent-based, UV, and water-based inks |

| Applications | Labels, flexible packaging, food packaging, and cartons | High-quality packaging, specialty labels, and decorative printing |

Introduction to Flexography and Gravure Printing

Flexography and gravure printing are two prominent techniques used in high-volume packaging and label production, leveraging flexible relief plates and engraved cylinders, respectively. Flexography utilizes fast-drying, water-based inks ideal for printing on a variety of surfaces including plastic, paper, and metallic films, while gravure printing excels in delivering fine detail and consistent image quality through etched cells filled with ink. Both processes are valued for their efficiency and ability to produce vibrant, durable prints but differ significantly in setup costs, speed, and typical applications such as flexible packaging for flexography versus high-quality magazines and decorative printing for gravure.

Key Differences Between Flexography and Gravure

Flexography uses flexible relief plates and fast-drying water or UV-based inks, making it ideal for high-speed packaging and label printing with moderate to high-quality output. Gravure printing employs engraved cylinders that deliver superior image resolution and rich color density, commonly preferred for long print runs and high-quality magazines or packaging. The primary differences lie in plate construction, print quality, and cost efficiency, with flexography excelling in versatility and gravure in detailed image reproduction.

Printing Process Overview: Flexography vs Gravure

Flexography utilizes flexible relief plates and fast-drying inks to print on a variety of substrates, making it ideal for packaging materials and labels. Gravure printing employs engraved cylinders that transfer ink directly onto the substrate, delivering high precision and consistent image quality suited for high-volume prints. Both processes differ significantly in plate-making techniques and ink application, impacting cost-efficiency and print detail.

Substrate Compatibility and Material Choices

Flexography offers exceptional substrate compatibility, efficiently printing on a diverse range of materials including plastics, foils, papers, and corrugated cartons, making it ideal for flexible packaging. Gravure printing excels with high-quality, continuous-tone images on materials like coated papers, films, and laminates, favoring smooth, consistent surfaces for optimal ink adhesion. Material choices in flexography support faster drying and adaptability to lightweight substrates, while gravure printing demands thicker, smoother substrates to achieve its superior image resolution and rich color depth.

Print Quality and Image Resolution Comparison

Flexography delivers high-quality prints suitable for packaging and labels, with moderate image resolution typically around 300-400 DPI, ideal for bold graphics and text. Gravure printing achieves superior print quality and finer image resolution, often exceeding 1000 DPI, producing detailed, crisp images with smooth tonal gradients perfect for high-volume, high-end applications. Your choice between them depends on the desired print detail and production efficiency for your project.

Production Speed and Efficiency

Flexography offers higher production speed and efficiency due to its quick plate changes and suitability for high-volume, short to medium runs. Gravure printing, while capable of producing superior print quality and ideal for very long runs, generally requires longer setup times and higher initial costs, impacting overall efficiency. Your choice depends on balancing speed and volume needs with budget constraints.

Cost Analysis: Flexography vs Gravure

Flexography exhibits lower initial setup costs due to its simpler plate-making process, making it ideal for short to medium print runs. Gravure printing involves higher upfront expenses for cylinder engraving and equipment, but offers cost efficiency in large volume runs due to faster production speeds and consistent print quality. Over time, gravure proves more economical for extensive projects, whereas flexography remains cost-effective for shorter runs and flexible substrates.

Environmental Impact and Sustainability

Flexography printing typically offers a more environmentally sustainable option compared to gravure printing due to its use of water-based inks and faster drying times, which reduce VOC emissions and energy consumption. Gravure printing, while capable of high-quality, long-run production, often involves solvent-based inks and higher material waste, increasing its environmental footprint. Your choice between these methods can significantly impact sustainability goals, especially if minimizing pollution and resource use is a priority.

Typical Applications and Industry Use Cases

Flexography excels in packaging applications such as food wrappers, labels, and flexible materials due to its fast drying and adaptability for high-volume runs. Gravure printing is preferred for high-quality, long-run projects like magazines, catalogs, and decorative laminates, offering superior image detail and color consistency. Your choice depends on production scale and print quality, with flexography favored in fast turnaround packaging and gravure dominating premium print media.

Choosing the Right Printing Method for Your Project

Selecting between flexography and gravure printing depends on factors such as project scale, print quality, and material type. Flexography excels in high-speed production with versatility for substrates like plastic, paper, and foil, making it ideal for packaging and labels. Gravure printing offers superior image quality and color consistency for long runs on materials like flexible packaging and magazines, though it requires higher setup costs and longer turnaround times.

Flexography vs gravure printing Infographic

libmatt.com

libmatt.com