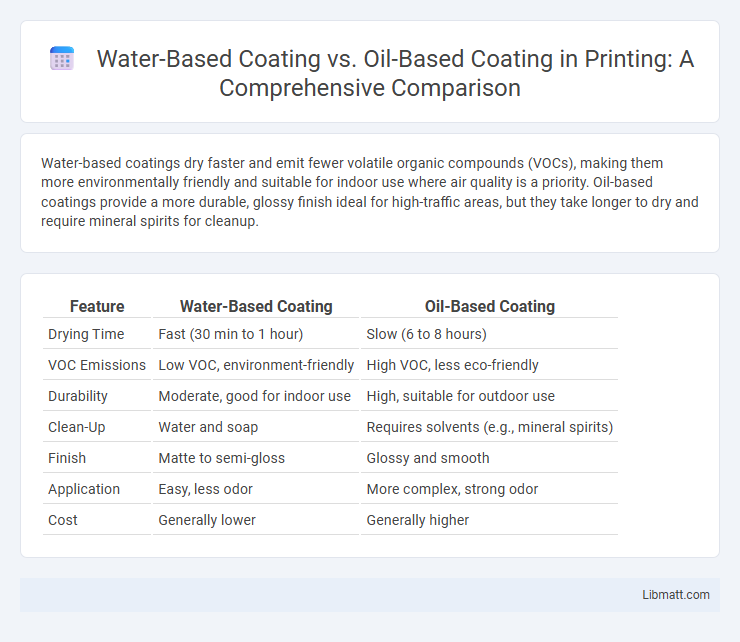

Water-based coatings dry faster and emit fewer volatile organic compounds (VOCs), making them more environmentally friendly and suitable for indoor use where air quality is a priority. Oil-based coatings provide a more durable, glossy finish ideal for high-traffic areas, but they take longer to dry and require mineral spirits for cleanup.

Table of Comparison

| Feature | Water-Based Coating | Oil-Based Coating |

|---|---|---|

| Drying Time | Fast (30 min to 1 hour) | Slow (6 to 8 hours) |

| VOC Emissions | Low VOC, environment-friendly | High VOC, less eco-friendly |

| Durability | Moderate, good for indoor use | High, suitable for outdoor use |

| Clean-Up | Water and soap | Requires solvents (e.g., mineral spirits) |

| Finish | Matte to semi-gloss | Glossy and smooth |

| Application | Easy, less odor | More complex, strong odor |

| Cost | Generally lower | Generally higher |

Introduction to Water-Based vs Oil-Based Coatings

Water-based coatings offer low VOC emissions, faster drying times, and easier cleanup compared to oil-based coatings, which provide superior durability and a smoother finish on surfaces. Your choice depends on the project requirements, with water-based coatings ideal for indoor applications and oil-based coatings suited for high-traffic or exterior use. Understanding these differences ensures optimal protection and aesthetic results for your surfaces.

Composition and Chemical Structure

Water-based coatings consist primarily of acrylic or latex resins suspended in water, offering lower levels of volatile organic compounds (VOCs) and faster drying times due to their hydrophilic chemical structure. Oil-based coatings contain alkyd resins derived from natural oils, which create a hydrophobic, durable film through oxidation and polymerization processes, resulting in higher VOC emissions and longer curing periods. Understanding the differences in chemical composition between these coatings helps you select the most suitable product for your surface protection and environmental preferences.

Application Methods

Water-based coatings typically require spray, brush, or roller application, offering faster drying times and easier cleanup with soap and water. Oil-based coatings benefit from brush or roller methods, providing a thicker, more durable finish suited for high-traffic areas but needing mineral spirits for cleaning. Choosing the right application method depends on your project's requirements for drying speed, durability, and maintenance convenience.

Drying and Curing Times

Water-based coatings typically dry faster, often within 1-2 hours, allowing for quicker recoating and less downtime in your project schedule. Oil-based coatings require longer drying and curing times, usually taking up to 24 hours to dry to the touch and several days to fully cure, providing a harder, more durable finish. Selecting the right coating depends on your timeline and desired durability, balancing faster drying times with the long-term performance you need.

Environmental Impact and VOC Emissions

Water-based coatings significantly reduce environmental impact by emitting fewer volatile organic compounds (VOCs) compared to oil-based coatings, which release higher levels of VOCs that contribute to air pollution and health hazards. Your choice of water-based coating supports improved indoor air quality and complies with stricter environmental regulations due to its lower toxicity and faster drying time. These coatings offer a safer, eco-friendly alternative while maintaining effective protection and durability for various surfaces.

Durability and Performance

Water-based coatings offer excellent durability with fast drying times and resistance to cracking and peeling, making them ideal for environments exposed to moisture. Oil-based coatings provide superior hardness and a smoother finish, excelling in high-traffic areas where long-lasting wear resistance is crucial. Your choice between the two should consider the specific performance needs of your project, such as exposure to elements and desired maintenance frequency.

Maintenance and Recoating Requirements

Water-based coatings offer easier maintenance with quicker drying times, allowing for faster recoating and less downtime. Oil-based coatings require longer curing periods and more intensive upkeep due to their slower drying and potential for yellowing or cracking over time. Choosing a water-based option can reduce your recoating frequency and simplify long-term maintenance tasks.

Cost Comparison

Water-based coatings typically cost less than oil-based coatings due to lower production expenses and simplified cleanup processes using water instead of solvents. Oil-based coatings often require more expensive raw materials and specialized disposal methods, increasing overall costs for users. Long-term expenses also favor water-based options because they emit fewer volatile organic compounds (VOCs), reducing regulatory compliance fees and environmental impact.

Best Use Cases for Each Type

Water-based coatings excel in interior applications, such as walls, ceilings, and furniture, due to their low VOC emissions, quick drying time, and easy cleanup with soap and water. Oil-based coatings offer superior durability and are ideal for high-traffic areas, exterior surfaces, and woodwork, providing a hard, glossy finish resistant to moisture and wear. Your choice depends on the project's environmental conditions, desired finish, and maintenance requirements.

Conclusion: Choosing the Right Coating

Water-based coatings offer faster drying times, lower VOC emissions, and easier cleanup, making them ideal for environmentally conscious projects and indoor use. Oil-based coatings provide superior durability, richer finishes, and better adhesion on certain surfaces, which suits heavy-traffic areas or exterior applications. Your choice depends on balancing environmental impact, drying time, and surface requirements to achieve the desired performance and aesthetic.

Water-Based Coating vs Oil-Based Coating Infographic

libmatt.com

libmatt.com