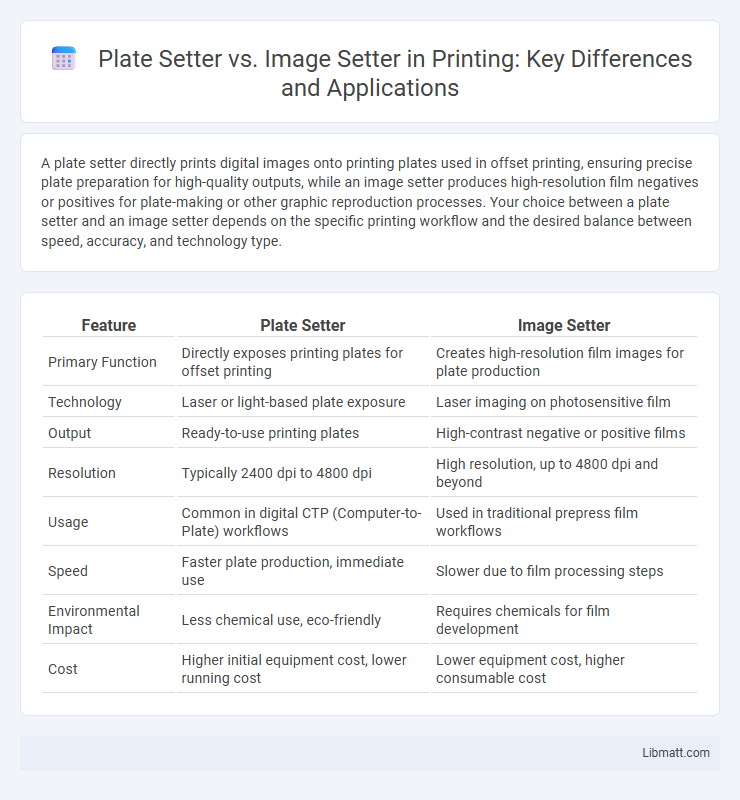

A plate setter directly prints digital images onto printing plates used in offset printing, ensuring precise plate preparation for high-quality outputs, while an image setter produces high-resolution film negatives or positives for plate-making or other graphic reproduction processes. Your choice between a plate setter and an image setter depends on the specific printing workflow and the desired balance between speed, accuracy, and technology type.

Table of Comparison

| Feature | Plate Setter | Image Setter |

|---|---|---|

| Primary Function | Directly exposes printing plates for offset printing | Creates high-resolution film images for plate production |

| Technology | Laser or light-based plate exposure | Laser imaging on photosensitive film |

| Output | Ready-to-use printing plates | High-contrast negative or positive films |

| Resolution | Typically 2400 dpi to 4800 dpi | High resolution, up to 4800 dpi and beyond |

| Usage | Common in digital CTP (Computer-to-Plate) workflows | Used in traditional prepress film workflows |

| Speed | Faster plate production, immediate use | Slower due to film processing steps |

| Environmental Impact | Less chemical use, eco-friendly | Requires chemicals for film development |

| Cost | Higher initial equipment cost, lower running cost | Lower equipment cost, higher consumable cost |

Introduction to Plate Setters and Image Setters

Plate setters and image setters are essential devices in the prepress process, converting digital files into printing plates or film negatives used in offset printing. Plate setters directly expose the printing plates with laser technology, enabling faster and more environmentally friendly workflows, while image setters create high-resolution film negatives for indirect plate making. Understanding the differences in technology and output quality can help optimize Your print production efficiency and final image fidelity.

Understanding Plate Setting Technology

Plate setters employ laser technology to directly image digital files onto printing plates, offering high precision and faster turnaround times in prepress workflows. Image setters, traditionally used in older prepress systems, use photographic processes to expose images onto film before plate creation, resulting in additional steps and longer processing time. Advancements in computer-to-plate (CTP) technology have made plate setters the industry standard, improving print quality and reducing material waste significantly.

The Basics of Image Setters Explained

Image setters are high-resolution devices used in printing to produce film or plates directly from digital files, ensuring precise and sharp images. Plate setters function similarly but specialize in exposing printing plates without intermediate film, streamlining the prepress process. Understanding the difference helps you choose the right equipment for accurate, efficient printing workflow management.

Key Differences Between Plate Setters and Image Setters

Plate setters and image setters are essential prepress devices in offset printing, with plate setters directly exposing digital images onto printing plates, while image setters produce high-resolution film negatives or positives for plate making. The key differences lie in their output forms--plate setters create plates ready for press, whereas image setters generate films requiring further processing. Plate setters offer faster turnaround and higher efficiency in modern workflows, contrasting with image setters' traditional use in film-based plate production.

Print Industry Applications: Plate Setter vs Image Setter

Plate setters and image setters serve critical roles in print industry applications, with plate setters primarily used to create printing plates for offset printing, enabling high-volume production with precise image transfer. Image setters directly expose film or plates through high-resolution laser imaging, essential for detailed prepress workflows in commercial printing environments. Choosing the right technology depends on your print run volume and required image quality, with plate setters favored for efficiency and image setters for superior resolution detail.

Output Quality: Plate Setter vs Image Setter Comparison

Plate setters deliver precise, high-resolution printing plates essential for modern offset printing, ensuring sharp lines and consistent color registration. Image setters produce high-quality raster images directly onto film or plates with superior grayscale and detail, ideal for intricate graphic designs. While both provide excellent output quality, plate setters excel in speed and efficiency for mass production, whereas image setters prioritize image fidelity and fine detail reproduction.

Workflow Efficiency and Speed Analysis

Plate setters offer faster processing speeds by automating plate creation directly from digital files, reducing manual intervention and minimizing downtime. Image setters provide high-resolution imaging ideal for detailed print jobs but typically operate at slower speeds, impacting overall workflow efficiency in high-volume environments. Choosing plate setters enhances throughput by streamlining prepress operations, whereas image setters are preferred for precision over speed in specialized print production.

Cost Considerations: Plate Setters and Image Setters

Plate setters typically offer a more cost-effective solution for mid-volume printing operations by reducing consumable expenses and maintenance needs compared to traditional image setters. Image setters, while initially more expensive due to higher equipment and film costs, provide superior image resolution and are preferred for high-precision applications demanding exceptional print quality. Evaluating total cost of ownership, including consumables, equipment lifespan, and labor, is essential when choosing between plate setters and image setters for specific printing workflows.

Maintenance and Longevity Factors

Plate setters require regular cleaning of the laser heads and mirrors to maintain image precision, with replacement parts readily available, ensuring extended machine life. Image setters, particularly those using complex film or chemical processes, demand routine calibration and chemical handling, which can shorten operational lifespan if maintenance is neglected. Proper upkeep of both technologies significantly influences longevity, with plate setters often favored for their lower maintenance intensity and longer durable components.

Choosing the Right Technology for Your Print Needs

Plate setters and image setters serve distinct roles in prepress printing technology, with plate setters directly exposing printing plates using digital data, optimizing for efficiency and cost-effectiveness in large-volume runs. Image setters produce high-resolution film negatives or positives for plate making, offering superior detail and quality for specialized printing tasks where precision is critical. Evaluating print volume, desired image quality, turnaround time, and budget helps in selecting the appropriate technology to meet specific production requirements.

Plate setter vs image setter Infographic

libmatt.com

libmatt.com