CTP plates use digital imaging technology to directly transfer your print image onto the plate, ensuring higher precision and faster turnaround compared to analog plates that require film negatives and chemical processing. The digital nature of CTP plates enhances image quality and reduces setup time, making them more efficient for modern printing workflows.

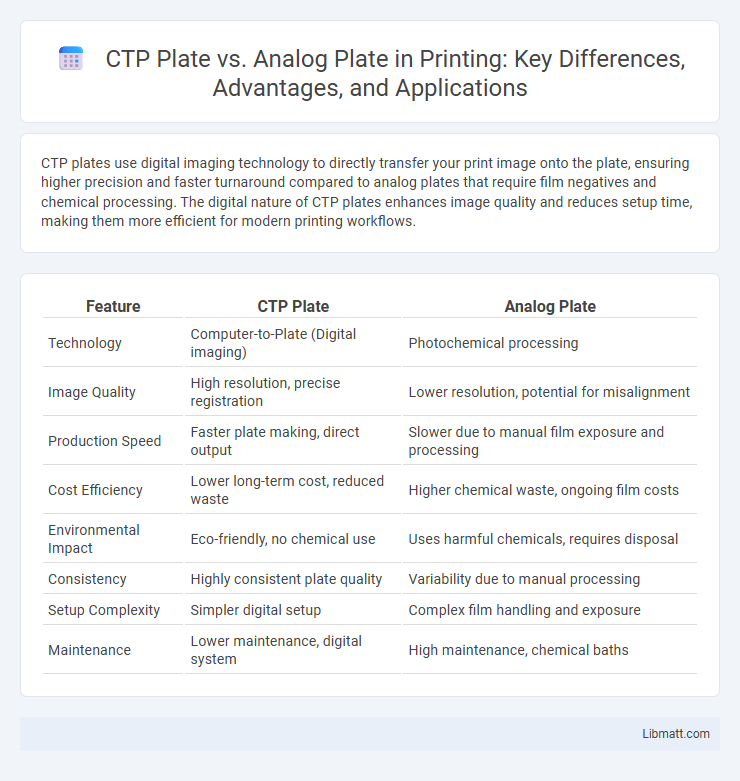

Table of Comparison

| Feature | CTP Plate | Analog Plate |

|---|---|---|

| Technology | Computer-to-Plate (Digital imaging) | Photochemical processing |

| Image Quality | High resolution, precise registration | Lower resolution, potential for misalignment |

| Production Speed | Faster plate making, direct output | Slower due to manual film exposure and processing |

| Cost Efficiency | Lower long-term cost, reduced waste | Higher chemical waste, ongoing film costs |

| Environmental Impact | Eco-friendly, no chemical use | Uses harmful chemicals, requires disposal |

| Consistency | Highly consistent plate quality | Variability due to manual processing |

| Setup Complexity | Simpler digital setup | Complex film handling and exposure |

| Maintenance | Lower maintenance, digital system | High maintenance, chemical baths |

Introduction to CTP and Analog Plates

CTP plates, or Computer-to-Plate technology, directly transfers digital images onto printing plates, eliminating the need for intermediate film processing used in analog plates. Analog plates require a film negative to be exposed chemically before plate development, which increases processing time and material usage. The digital precision of CTP plates enhances print quality and consistency, making them a more efficient choice compared to traditional analog plates.

What Are CTP Plates?

CTP plates, or Computer-to-Plate plates, are photopolymer printing plates created directly from digital files using laser technology, eliminating the need for film negatives used in traditional analog plate-making. These plates offer higher precision, faster production times, and improved image quality compared to analog plates, which require a film-based workflow. The digital process reduces errors and material waste, enhancing overall printing efficiency.

What Are Analog Plates?

Analog plates refer to traditional printing plates used in offset printing that require manual preparation through photographic processes, involving exposure and chemical development. These plates are typically made from metal, such as aluminum, and must be physically processed before being mounted on the press. Unlike Computer-to-Plate (CTP) technology, analog plates do not directly integrate with digital workflows, resulting in longer production times and increased material usage.

Plate Production Process Comparison

CTP plates utilize digital files to directly image plates through laser technology, eliminating multiple manual steps common in analog plate production. Analog plates require film negatives, film processing, and manual plate exposure, increasing production time and potential for errors. Your printing workflow benefits from CTP's streamlined, faster plate production process that enhances accuracy and consistency.

Print Quality Differences

CTP plates deliver superior print quality compared to analog plates due to their precise digital imaging technology that eliminates film and minimizes errors. The high resolution and consistent plate exposure in CTP ensure sharper images, better dot reproduction, and smoother gradients. Your prints benefit from enhanced clarity and greater detail, resulting in professional and reliable output.

Cost Efficiency and Investment

CTP plates offer greater cost efficiency by eliminating film processing expenses and reducing material waste compared to analog plates. Your initial investment in CTP technology is higher, but lower long-term operational costs and faster turnaround times provide a quicker return on investment. Over time, CTP systems optimize printing workflows, enhancing overall profitability through reduced labor and consumable costs.

Environmental Impact

CTP plates significantly reduce environmental impact by eliminating chemical processing and waste associated with analog plate production, such as hazardous developers and fixers. The digital imaging process of CTP plates lowers energy consumption and minimizes water usage compared to analog methods. Recyclability and reduced chemical exposure make CTP technology a more sustainable choice for printing workflows.

Workflow Speed and Automation

CTP plates significantly enhance workflow speed and automation compared to analog plates by eliminating manual film handling and chemical processing. Digital file-to-plate technology allows for faster plate production, reducing setup times and minimizing errors. Integration with automated plate setters streamlines prepress operations, increasing overall pressroom efficiency.

Maintenance and Durability

CTP plates exhibit superior durability with fewer scratches and longer lifespan compared to analog plates, reducing the frequency of replacements. Maintenance requirements for CTP plates are minimal due to their digital production process, which eliminates chemical processing and associated wear. Analog plates demand regular chemical handling and careful cleaning to prevent damage, increasing maintenance efforts and costs.

Choosing the Right Plate for Your Print Shop

Choosing the right plate for your print shop depends on balancing quality, efficiency, and budget. CTP plates offer higher resolution, faster turnaround times, and consistent performance, ideal for shops prioritizing precision and productivity. Analog plates may serve smaller operations with lower initial costs but require more manual handling and longer setup times.

CTP plate vs analog plate Infographic

libmatt.com

libmatt.com