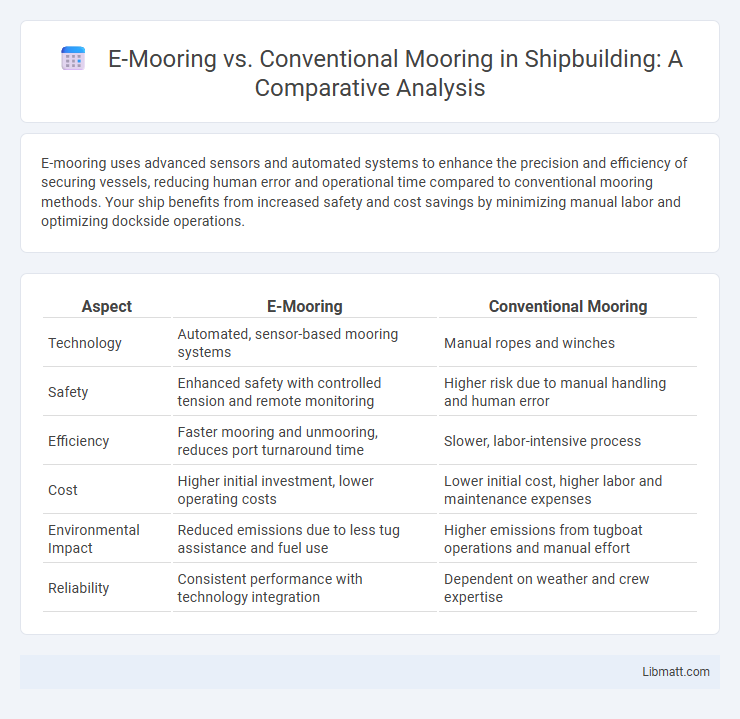

E-mooring uses advanced sensors and automated systems to enhance the precision and efficiency of securing vessels, reducing human error and operational time compared to conventional mooring methods. Your ship benefits from increased safety and cost savings by minimizing manual labor and optimizing dockside operations.

Table of Comparison

| Aspect | E-Mooring | Conventional Mooring |

|---|---|---|

| Technology | Automated, sensor-based mooring systems | Manual ropes and winches |

| Safety | Enhanced safety with controlled tension and remote monitoring | Higher risk due to manual handling and human error |

| Efficiency | Faster mooring and unmooring, reduces port turnaround time | Slower, labor-intensive process |

| Cost | Higher initial investment, lower operating costs | Lower initial cost, higher labor and maintenance expenses |

| Environmental Impact | Reduced emissions due to less tug assistance and fuel use | Higher emissions from tugboat operations and manual effort |

| Reliability | Consistent performance with technology integration | Dependent on weather and crew expertise |

Introduction to Mooring Systems

Mooring systems secure vessels at docks or offshore locations, preventing movement caused by wind, currents, or waves. Conventional mooring uses ropes, chains, and anchors that require manual handling and regular maintenance. E-mooring integrates automated technology, sensors, and real-time data to enhance safety, reduce manpower, and optimize docking efficiency.

What is E-Mooring?

E-Mooring is an advanced docking technology that uses real-time data, sensors, and automation to enhance the precision and safety of mooring operations for ships. Unlike conventional mooring, which relies on manual handling of ropes and human judgment, E-Mooring integrates IoT devices and digital control systems to optimize vessel positioning, reduce risks, and lower operational costs. This technology significantly improves turnaround times and environmental sustainability by minimizing emissions from auxiliary engines during docking procedures.

Conventional Mooring: Overview and Types

Conventional mooring involves securing a vessel using ropes, chains, or anchors attached to fixed points such as docks or buoys, providing stability during loading and unloading. Common types include single-point mooring, multi-point mooring, and dolphin mooring, each designed for specific vessel sizes and environmental conditions. Understanding the limitations of conventional mooring, such as susceptibility to weather and manual labor intensity, helps you evaluate its suitability compared to modern alternatives like e-mooring.

Key Differences Between E-Mooring and Conventional Mooring

E-mooring utilizes advanced sensor technology, real-time data transmission, and automated control systems to enhance the precision and safety of vessel docking, whereas conventional mooring relies on manual procedures and physical lines. E-mooring reduces human error, improves turnaround time, and enables remote monitoring of mooring forces, contrasting with the labor-intensive and less dynamic nature of traditional mooring methods. Key differences include integration of IoT devices, automated tension adjustments, and environmental impact reduction through minimized physical infrastructure in e-mooring systems.

Environmental Impact: E-Mooring vs Conventional Mooring

E-mooring systems significantly reduce environmental impact by minimizing fuel consumption and emissions through automated, electric-powered vessel positioning, unlike conventional mooring that typically relies on tugboats and anchors, causing higher pollution and seabed disturbance. The precise control of e-mooring decreases underwater noise and prevents damage to marine ecosystems, offering a sustainable alternative to traditional methods. Your choice of e-mooring supports sustainable maritime operations with lowered carbon footprints and enhanced marine habitat protection.

Safety and Reliability Factors

E-mooring systems enhance safety by reducing the risk of human error through automated controls and real-time monitoring, which minimizes accidents during docking. Conventional mooring relies heavily on manual labor, increasing exposure to hazards like rope snaps and miscommunication among crew members. Your operations benefit from e-mooring's consistent reliability and predictive maintenance, ensuring safer and more efficient vessel securing processes.

Cost Analysis and Economic Considerations

E-mooring systems offer significant cost savings over conventional mooring by reducing the need for tugboat services and crew labor, which lowers operational expenses. The initial investment in e-mooring technology is offset by decreased fuel consumption and minimized environmental penalties associated with traditional mooring. Long-term economic benefits include improved turnaround times and enhanced port efficiency, contributing to increased revenue generation and lower overall cost per vessel call.

Technological Advancements in Mooring

E-mooring systems leverage advanced sensors, IoT connectivity, and automation to provide real-time monitoring and precise control of mooring forces, enhancing safety and operational efficiency compared to conventional mooring. These technological advancements reduce human error, enable remote diagnostics, and optimize resource allocation during docking and undocking procedures. Your vessel benefits from improved situational awareness and lower maintenance costs through the integration of smart mooring solutions.

Applications and Use Cases

E-mooring systems are widely applied in modern ports and offshore facilities for automated ship docking, significantly enhancing operational efficiency and safety during cargo handling and fuel transfer operations. Conventional mooring remains prevalent in smaller ports and traditional maritime settings where manual control is preferred for tasks like berthing fishing vessels or leisure boats. The integration of e-mooring technology is particularly beneficial in high-traffic terminals, LNG terminals, and shipyards requiring precise positioning and rapid turnaround times.

Future Trends in Mooring Solutions

E-mooring systems represent the future of mooring solutions by integrating advanced sensors and automated controls to enhance vessel positioning accuracy and safety compared to conventional mooring methods. Smart mooring technologies reduce reliance on manual labor and improve operational efficiency through real-time environmental data analysis and remote monitoring capabilities. Industry trends indicate a growing adoption of eco-friendly electric mooring systems that minimize carbon emissions and support sustainable port operations worldwide.

E-mooring vs conventional mooring Infographic

libmatt.com

libmatt.com