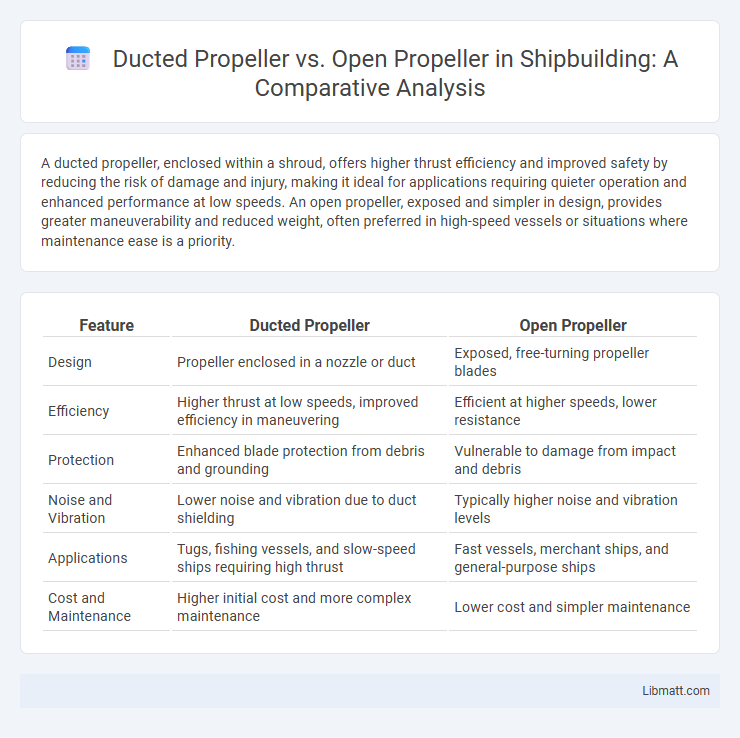

A ducted propeller, enclosed within a shroud, offers higher thrust efficiency and improved safety by reducing the risk of damage and injury, making it ideal for applications requiring quieter operation and enhanced performance at low speeds. An open propeller, exposed and simpler in design, provides greater maneuverability and reduced weight, often preferred in high-speed vessels or situations where maintenance ease is a priority.

Table of Comparison

| Feature | Ducted Propeller | Open Propeller |

|---|---|---|

| Design | Propeller enclosed in a nozzle or duct | Exposed, free-turning propeller blades |

| Efficiency | Higher thrust at low speeds, improved efficiency in maneuvering | Efficient at higher speeds, lower resistance |

| Protection | Enhanced blade protection from debris and grounding | Vulnerable to damage from impact and debris |

| Noise and Vibration | Lower noise and vibration due to duct shielding | Typically higher noise and vibration levels |

| Applications | Tugs, fishing vessels, and slow-speed ships requiring high thrust | Fast vessels, merchant ships, and general-purpose ships |

| Cost and Maintenance | Higher initial cost and more complex maintenance | Lower cost and simpler maintenance |

Introduction: Ducted vs Open Propeller Overview

Ducted propellers feature a shrouded design that enhances thrust efficiency and reduces noise compared to open propellers, which have exposed blades offering simpler construction and lower cost. The duct improves water flow control and protects the blades from damage, making it ideal for applications requiring precision and safety. Your choice between ducted and open propellers depends on factors like vessel speed, maneuverability, and operational environment.

Design Features: Structure and Components

Ducted propellers feature a shrouded ring or nozzle surrounding the blades, enhancing thrust efficiency and reducing noise by controlling water flow, while open propellers consist of exposed blades directly mounted on a hub for simpler design and easier maintenance. The duct structure typically includes a stator assembly to straighten water flow and improve propulsion performance, contrasting with open propellers that rely solely on blade geometry for hydrodynamic efficiency. You benefit from the ducted propeller's optimized structure in applications requiring higher thrust and quieter operation, whereas open propellers offer versatility and cost-effective repairs.

Thrust Efficiency Comparison

Ducted propellers generally offer higher thrust efficiency at low speeds and in constrained water conditions due to the duct's ability to reduce tip vortex losses and improve water flow velocity through the propeller. Open propellers tend to have higher efficiency in open waters and at varying speed ranges, as they experience less drag without the duct structure. Efficiency differences depend on operational parameters such as vessel speed, load conditions, and propeller design, with ducted propellers excelling in static thrust and open propellers favored for cruising efficiency.

Performance in Different Operating Conditions

Ducted propellers offer improved thrust and efficiency in low-speed and high-load conditions due to the shrouded design reducing tip vortices and cavitation. Open propellers perform better at higher speeds and in conditions requiring rapid maneuverability, benefiting from less hydrodynamic resistance. Your choice depends on the specific operating environment, with ducted propellers excelling in pushing vessels through heavy water resistance and open propellers maximizing speed and agility.

Noise and Vibration Levels

Ducted propellers typically generate lower noise and vibration levels due to the surrounding shroud that streamlines water flow and reduces cavitation. Open propellers often experience higher noise emissions caused by turbulent water interaction and blade-tip vortices. This makes ducted propellers preferable in applications requiring quieter operation and minimized vibration impact.

Cavitation and Erosion Resistance

Ducted propellers significantly reduce cavitation by optimizing water flow through the shroud, minimizing pressure differences that cause vapor bubble formation. This reduction in cavitation also enhances erosion resistance, as fewer vapor bubbles collapse near the propeller surface, leading to less material wear and longer lifespan. Choosing a ducted propeller can improve your vessel's operational durability and performance in challenging marine environments.

Fuel Consumption and Cost Implications

Ducted propellers typically offer improved fuel efficiency compared to open propellers due to their enhanced thrust generation and reduced cavitation, leading to lower operational fuel costs. The initial cost of ducted propeller systems is generally higher because of their complex design and manufacturing requirements, but long-term savings from fuel efficiency can offset these expenses. Maintenance costs for open propellers tend to be lower, making them more cost-effective for vessels with simpler operational needs.

Application Suitability: Marine and Aeronautical Uses

Ducted propellers, also known as Kort nozzles, are highly effective in marine applications where increased thrust and enhanced maneuverability at low speeds are essential, making them ideal for tugboats and fishing vessels. Open propellers excel in aeronautical uses due to their lightweight design and efficiency at high speeds, commonly featured in aircraft and drones for optimal thrust-to-weight ratios. Marine vessels benefit from ducted propellers' protection against debris and improved fuel efficiency, whereas open propellers remain preferred in aviation for demonstrating superior aerodynamic performance and reduced drag.

Maintenance Requirements and Longevity

Ducted propellers typically demand less frequent maintenance due to their protective shroud, which reduces damage from debris and improves durability. Open propellers, while easier and cheaper to maintain or replace, are more exposed to impacts and wear, potentially shortening their lifespan. Choosing a ducted propeller can extend the longevity of your propulsion system and reduce upkeep costs over time.

Future Trends and Innovations in Propeller Technology

Ducted propeller technology is evolving with advancements in noise reduction, fuel efficiency, and enhanced thrust performance, driven by innovations in computational fluid dynamics and additive manufacturing. Open propellers benefit from lightweight composite materials and adaptive blade designs that improve aerodynamics and reduce vibration for increased durability and performance. Your choice between ducted and open propellers will hinge on future integration of smart sensors and AI-driven control systems enhancing propulsion efficiency and adaptive response to varying operating conditions.

Ducted propeller vs open propeller Infographic

libmatt.com

libmatt.com