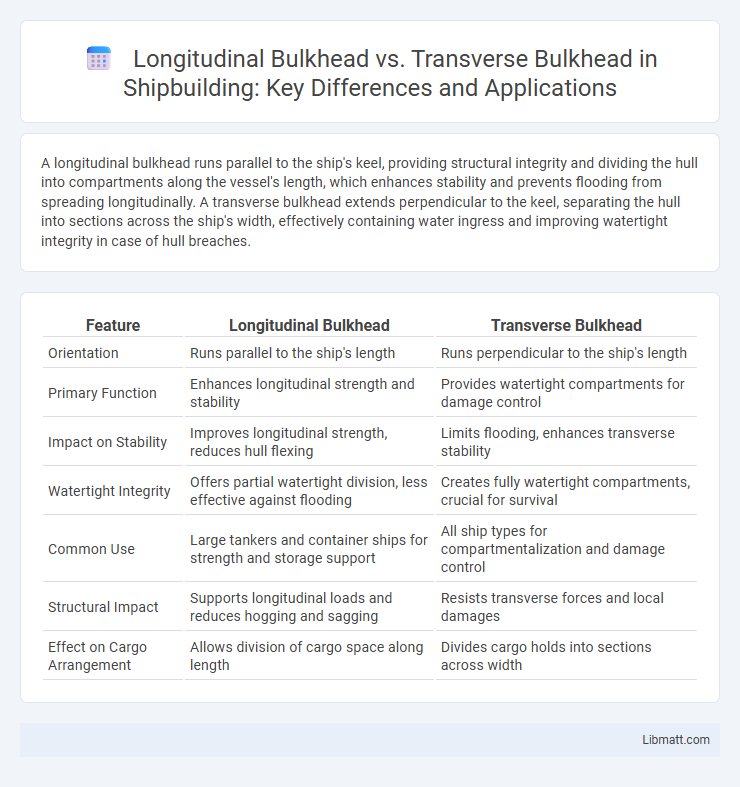

A longitudinal bulkhead runs parallel to the ship's keel, providing structural integrity and dividing the hull into compartments along the vessel's length, which enhances stability and prevents flooding from spreading longitudinally. A transverse bulkhead extends perpendicular to the keel, separating the hull into sections across the ship's width, effectively containing water ingress and improving watertight integrity in case of hull breaches.

Table of Comparison

| Feature | Longitudinal Bulkhead | Transverse Bulkhead |

|---|---|---|

| Orientation | Runs parallel to the ship's length | Runs perpendicular to the ship's length |

| Primary Function | Enhances longitudinal strength and stability | Provides watertight compartments for damage control |

| Impact on Stability | Improves longitudinal strength, reduces hull flexing | Limits flooding, enhances transverse stability |

| Watertight Integrity | Offers partial watertight division, less effective against flooding | Creates fully watertight compartments, crucial for survival |

| Common Use | Large tankers and container ships for strength and storage support | All ship types for compartmentalization and damage control |

| Structural Impact | Supports longitudinal loads and reduces hogging and sagging | Resists transverse forces and local damages |

| Effect on Cargo Arrangement | Allows division of cargo space along length | Divides cargo holds into sections across width |

Introduction to Bulkheads in Ship Design

Bulkheads in ship design are critical structural elements that partition the vessel's hull into watertight compartments to enhance safety and stability. Longitudinal bulkheads run parallel to the ship's length, improving hull strength and reducing hull girder stresses, while transverse bulkheads extend across the width, providing compartmentalization to prevent flooding spread. Both types of bulkheads are essential for maintaining structural integrity and ensuring vessel survivability during emergencies.

Definition of Longitudinal Bulkheads

Longitudinal bulkheads are vertical partitions running lengthwise in a ship or structure, dividing the interior into multiple compartments to enhance stability and reduce flooding risks. Unlike transverse bulkheads, which run across the width of a vessel, longitudinal bulkheads provide support along the ship's length and improve structural integrity against longitudinal stresses. These bulkheads are crucial for maintaining watertight integrity and contribute significantly to a ship's overall strength and safety during navigation.

Definition of Transverse Bulkheads

Transverse bulkheads are vertical partitions that run across the width of a ship, dividing it into separate watertight compartments to improve structural integrity and safety. Unlike longitudinal bulkheads, which run along the length of the vessel, transverse bulkheads help contain flooding in specific sections, preventing water from spreading fore and aft. Your ship's safety heavily depends on the strategic placement of these transverse bulkheads to maintain buoyancy and stability during emergencies.

Structural Role of Longitudinal Bulkheads

Longitudinal bulkheads provide critical structural support by running parallel to the ship's length, enhancing hull strength and resisting bending stresses during heavy seas. They contribute to the vessel's longitudinal rigidity and help distribute loads evenly across the hull, improving overall stability and integrity. Unlike transverse bulkheads, which primarily compartmentalize the ship to enhance watertight safety, longitudinal bulkheads focus on reinforcing the ship's structural framework along its main axis.

Structural Role of Transverse Bulkheads

Transverse bulkheads serve a critical structural role by providing lateral strength and dividing a ship into watertight compartments, which helps prevent flooding from spreading in case of hull breach. Their placement at strategic intervals enhances the vessel's overall rigidity and resistance to hull deformation under various loading conditions. You rely on transverse bulkheads to maintain the integrity and safety of the ship's structure during operations at sea.

Impact on Ship Stability and Strength

Longitudinal bulkheads run parallel to the ship's length, enhancing longitudinal strength and improving hull rigidity, which is crucial for resisting bending moments caused by waves. Transverse bulkheads extend across the ship's width, playing a vital role in compartmentalization and preventing flooding spread, thereby boosting transverse stability and damage resistance. Your ship's overall structural integrity and stability depend on the strategic combination of both bulkhead types to balance strength against longitudinal flexing and transverse flooding risks.

Advantages of Longitudinal Bulkheads

Longitudinal bulkheads enhance structural integrity by efficiently distributing hull stresses along the ship's length, improving overall strength and reducing deformation. They provide better compartmentalization for liquid cargo tanks, minimizing free surface effects and enhancing stability during voyages. This design also allows for more flexible use of internal space, optimizing cargo arrangements and improving safety through improved watertight separation.

Advantages of Transverse Bulkheads

Transverse bulkheads provide superior compartmentalization in ship design, enhancing structural integrity by dividing the hull into watertight sections that limit flooding in case of hull breaches. They enable more efficient load distribution across the vessel's width, improving stability and resistance against bending stresses. The installation of transverse bulkheads also facilitates easier access to cargo holds and machinery spaces, streamlining maintenance and operational procedures.

Typical Applications and Vessel Types

Longitudinal bulkheads are typically used in vessels like tankers and bulk carriers to enhance hull strength and provide compartmentalization along the ship's length, improving stability and cargo segregation. Transverse bulkheads are common in passenger ships, container vessels, and naval ships, dividing the hull into watertight compartments to increase safety and minimize flooding risks. Both bulkhead types are integral to ship design, with longitudinal bulkheads favoring cargo optimization and transverse bulkheads prioritizing safety and structural integrity.

Choosing Between Longitudinal and Transverse Bulkheads

Choosing between longitudinal and transverse bulkheads depends on the vessel's structural requirements and intended use. Longitudinal bulkheads run parallel to the ship's length, providing enhanced resistance against bending forces and improving hull integrity in rough seas. Transverse bulkheads, placed perpendicular to the keel, offer superior compartmentalization, improving buoyancy and damage control in case of hull breaches or flooding.

Longitudinal bulkhead vs transverse bulkhead Infographic

libmatt.com

libmatt.com