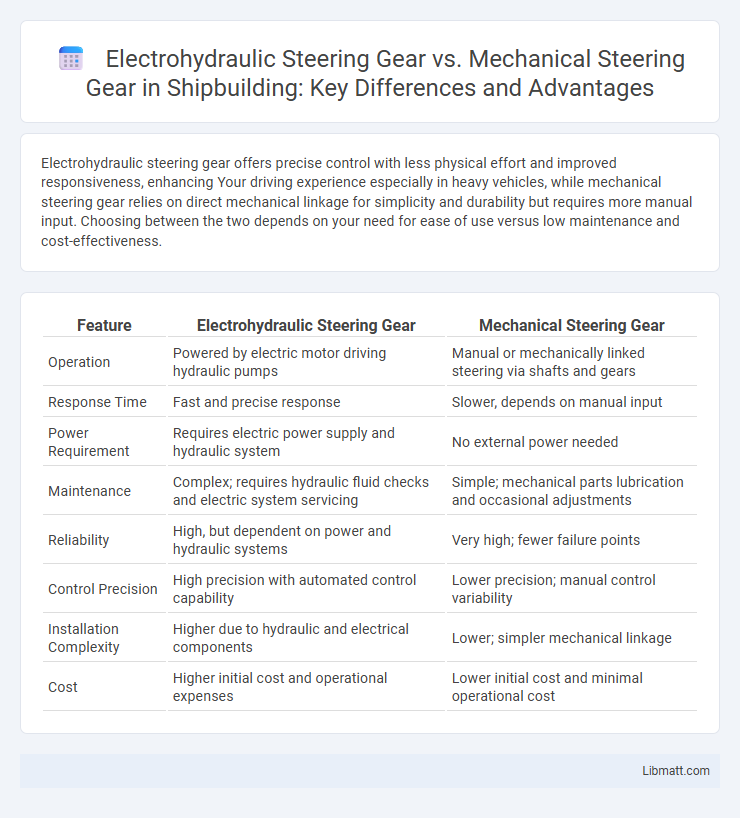

Electrohydraulic steering gear offers precise control with less physical effort and improved responsiveness, enhancing Your driving experience especially in heavy vehicles, while mechanical steering gear relies on direct mechanical linkage for simplicity and durability but requires more manual input. Choosing between the two depends on your need for ease of use versus low maintenance and cost-effectiveness.

Table of Comparison

| Feature | Electrohydraulic Steering Gear | Mechanical Steering Gear |

|---|---|---|

| Operation | Powered by electric motor driving hydraulic pumps | Manual or mechanically linked steering via shafts and gears |

| Response Time | Fast and precise response | Slower, depends on manual input |

| Power Requirement | Requires electric power supply and hydraulic system | No external power needed |

| Maintenance | Complex; requires hydraulic fluid checks and electric system servicing | Simple; mechanical parts lubrication and occasional adjustments |

| Reliability | High, but dependent on power and hydraulic systems | Very high; fewer failure points |

| Control Precision | High precision with automated control capability | Lower precision; manual control variability |

| Installation Complexity | Higher due to hydraulic and electrical components | Lower; simpler mechanical linkage |

| Cost | Higher initial cost and operational expenses | Lower initial cost and minimal operational cost |

Introduction to Ship Steering Gear Systems

Ship steering gear systems are crucial for maneuvering vessels efficiently and safely, consisting primarily of electrohydraulic and mechanical types. Electrohydraulic steering gear combines hydraulic power with electrical controls, offering precise handling, reduced manual effort, and enhanced reliability for modern ships. Your choice between these systems impacts vessel responsiveness, maintenance complexity, and overall steering performance.

Overview of Electrohydraulic Steering Gear

Electrohydraulic steering gear combines hydraulic power with electronic control units, offering precise and responsive steering compared to traditional mechanical systems. This technology enhances maneuverability in modern vessels by automatically adjusting hydraulic pressure based on input signals, reducing operator effort and improving safety. Your vessel benefits from smoother handling and reduced maintenance requirements due to fewer mechanical linkages and wear points.

Overview of Mechanical Steering Gear

Mechanical steering gear relies on physical linkages and gears to transmit steering input from the helm directly to the rudder, offering simplicity and durability. This traditional system requires manual effort, which can increase with boat size, and offers direct feedback from the water to your hands. Mechanical steering gears are favored for their reliability and ease of maintenance, especially in smaller vessels where precise control and straightforward operation are essential.

Key Components Comparison

Electrohydraulic steering gear features an electric motor, hydraulic pump, and control unit, enabling precise steering assistance and energy efficiency. Mechanical steering gear relies on physical linkages such as a steering wheel shaft, pitman arm, and drag link to directly transfer driver input to the wheels, offering simplicity and durability. The integration of sensors and electronic controls in electrohydraulic systems markedly improves responsiveness over traditional mechanical components.

Performance and Responsiveness Analysis

Electrohydraulic steering gear offers superior performance and responsiveness compared to mechanical steering gear due to its integration of electronic controls with hydraulic power, enabling precise and instantaneous adjustments. The system's ability to modulate steering torque dynamically reduces operator effort and enhances maneuverability, especially in high-speed or heavy-load scenarios. Mechanical steering gear lacks this adaptive feedback, often resulting in slower response times and increased physical demand on the operator.

Reliability and Maintenance Requirements

Electrohydraulic steering gear offers higher reliability with fewer moving parts and enhanced diagnostic capabilities compared to traditional mechanical steering gear, which is prone to wear and requires regular lubrication and adjustment. Maintenance for electrohydraulic systems is generally less frequent and involves checking electrical components and hydraulic fluid levels, while mechanical steering demands consistent inspection of cables, linkages, and gears for wear and alignment. Your choice impacts downtime and repair costs, with electrohydraulic steering providing improved operational efficiency through reduced maintenance intervals.

Energy Efficiency and Power Consumption

Electrohydraulic steering gear systems offer improved energy efficiency by activating the hydraulic pump only when steering input is detected, significantly reducing power consumption compared to mechanical steering gear systems that operate continuously. The targeted hydraulic assistance in electrohydraulic configurations minimizes engine load, resulting in lower fuel consumption and decreased greenhouse gas emissions. In contrast, mechanical steering gear relies on constant mechanical linkage, which leads to higher energy usage and less responsive power management during vessel maneuvering.

Safety Features and Redundancies

Electrohydraulic steering gear offers enhanced safety features and redundancies through electronic monitoring systems that detect malfunctions and automatically activate backup components, ensuring continued vessel control during steering failures. Mechanical steering gear relies on robust, manually operated linkages that provide inherent reliability but lack automated fault detection and rapid redundancy activation, requiring immediate human intervention in case of failure. Your choice of electrohydraulic systems provides advanced fail-safes like dual pumps and electronic alarms, significantly improving operational safety compared to traditional mechanical systems.

Application Suitability and Industry Trends

Electrohydraulic steering gear offers enhanced precision and reduced maintenance demands, making it suitable for modern commercial vessels and offshore platforms requiring automated control systems. Mechanical steering gear remains preferred in smaller boats and traditional ships due to its simplicity, reliability, and lower upfront costs. Industry trends indicate a growing shift towards electrohydraulic systems driven by advancements in digital integration and energy efficiency in maritime navigation.

Cost Considerations and Long-Term Value

Electrohydraulic steering gear typically involves higher upfront costs due to advanced components and integration complexity, but it offers greater fuel efficiency and reduced maintenance expenses over time. Mechanical steering gear systems generally present lower initial investment and simpler repairs but may incur higher long-term operational costs due to wear and energy inefficiency. Evaluating total cost of ownership reveals electrohydraulic systems provide better long-term value through enhanced performance, durability, and operational savings.

Electrohydraulic steering gear vs mechanical steering gear Infographic

libmatt.com

libmatt.com