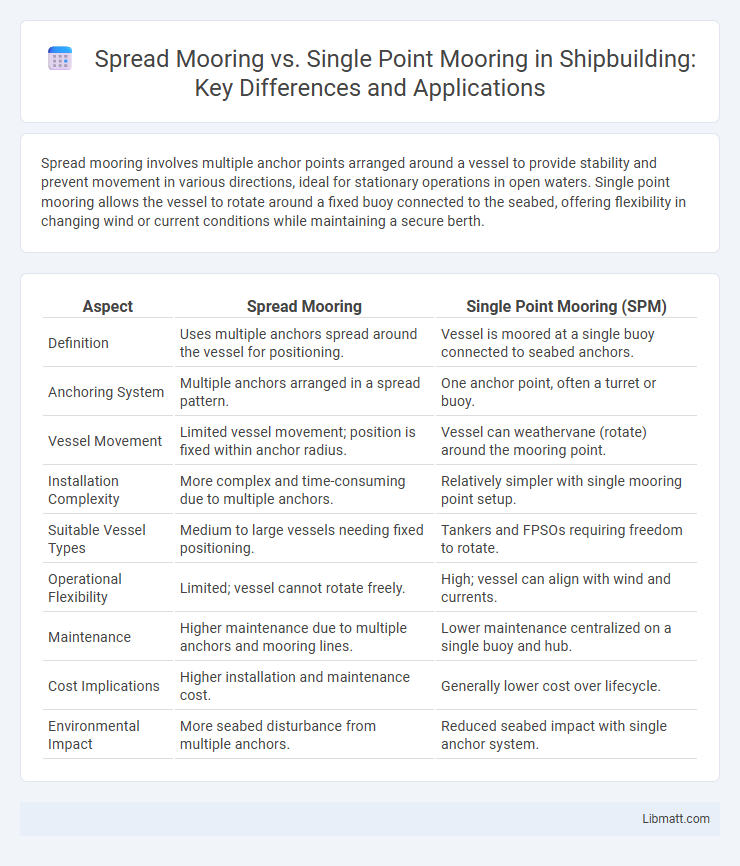

Spread mooring involves multiple anchor points arranged around a vessel to provide stability and prevent movement in various directions, ideal for stationary operations in open waters. Single point mooring allows the vessel to rotate around a fixed buoy connected to the seabed, offering flexibility in changing wind or current conditions while maintaining a secure berth.

Table of Comparison

| Aspect | Spread Mooring | Single Point Mooring (SPM) |

|---|---|---|

| Definition | Uses multiple anchors spread around the vessel for positioning. | Vessel is moored at a single buoy connected to seabed anchors. |

| Anchoring System | Multiple anchors arranged in a spread pattern. | One anchor point, often a turret or buoy. |

| Vessel Movement | Limited vessel movement; position is fixed within anchor radius. | Vessel can weathervane (rotate) around the mooring point. |

| Installation Complexity | More complex and time-consuming due to multiple anchors. | Relatively simpler with single mooring point setup. |

| Suitable Vessel Types | Medium to large vessels needing fixed positioning. | Tankers and FPSOs requiring freedom to rotate. |

| Operational Flexibility | Limited; vessel cannot rotate freely. | High; vessel can align with wind and currents. |

| Maintenance | Higher maintenance due to multiple anchors and mooring lines. | Lower maintenance centralized on a single buoy and hub. |

| Cost Implications | Higher installation and maintenance cost. | Generally lower cost over lifecycle. |

| Environmental Impact | More seabed disturbance from multiple anchors. | Reduced seabed impact with single anchor system. |

Introduction to Mooring Systems

Mooring systems secure vessels in place, ensuring stability and safety during loading, unloading, or stationary operations. Spread mooring uses multiple anchors or mooring lines arranged around the vessel to distribute forces evenly, providing enhanced stability in various weather conditions. Single point mooring relies on a single buoy or anchor, allowing the vessel to rotate freely, which is ideal for offshore loading and unloading but requires careful management of environmental forces.

Overview of Spread Mooring

Spread mooring systems use multiple anchors strategically positioned around a vessel to maintain stability and allow precise positioning in various marine environments. These systems distribute the load evenly across several anchor lines, enhancing safety and operational flexibility compared to single point mooring. Spread mooring is ideal for larger offshore platforms and floating production units requiring robust station-keeping capabilities.

Overview of Single Point Mooring

Single Point Mooring (SPM) is an offshore mooring system that allows vessels to remain anchored at a single location while rotating freely around the mooring point, minimizing vessel strain and facilitating efficient loading or offloading of cargo such as crude oil or liquefied natural gas. Unlike Spread Mooring that uses multiple anchor points spread over a broad area to secure a vessel's position, SPM systems utilize a buoy anchored by a single mooring line attached to the seabed, offering high operational flexibility in various water depths and sea conditions. Your choice of mooring system significantly impacts operational safety, vessel maneuverability, and ongoing maintenance costs in offshore operations.

Key Differences Between Spread and Single Point Mooring

Spread mooring systems anchor vessels at multiple points on the seabed, providing enhanced stability and load distribution, ideal for various water depths and environmental conditions. Single point mooring (SPM) uses a single buoy connected to the seabed, allowing the vessel to rotate freely around the mooring point, which is optimal for tanker loading and unloading in deep waters. Key differences include the spread mooring's fixed position and multiple anchorage versus the SPM's rotational capability and singular anchorage, affecting maneuverability, installation complexity, and maintenance.

Advantages of Spread Mooring

Spread mooring systems offer superior stability and load distribution by anchoring a vessel at multiple points, reducing stress on each individual anchor and minimizing vessel movement in harsh marine conditions. These systems enhance safety and operational efficiency, especially for large ships or floating structures in deepwater environments. Spread mooring also provides greater flexibility in positioning and maintaining the vessel, accommodating dynamic environmental forces such as wind, waves, and currents more effectively than single point mooring.

Advantages of Single Point Mooring

Single Point Mooring (SPM) offers superior flexibility for tanker operations, enabling vessels to weathervane freely around the mooring point, which reduces stress on the mooring system and enhances safety during adverse weather conditions. SPM systems support quick and efficient loading and unloading processes, minimizing berth occupancy time and optimizing port operations. The ability of SPM to accommodate large tankers offshore reduces the need for deepwater port infrastructure, lowering environmental impact and construction costs.

Limitations and Challenges of Each System

Spread mooring systems face limitations including high installation costs and complexity in dynamic marine environments, where the multiple anchor points can restrict vessel maneuverability and increase seabed impact. Single point mooring systems encounter challenges such as limited load capacity and vulnerability to harsh weather conditions, which can compromise stability and increase operational risks during extreme sea states. Both systems require careful site assessment and maintenance to mitigate risks associated with mooring line fatigue and seabed conditions.

Applications and Suitability

Spread mooring systems are ideal for larger offshore platforms requiring enhanced stability in multiple directions, making them suitable for deepwater drilling and production facilities. Single point mooring (SPM) systems excel in tanker loading and unloading operations due to their ability to allow vessels to weathervane freely around a buoy, ensuring safe and efficient transfer of fluids. Your choice between spread mooring and single point mooring depends on operational requirements such as water depth, vessel size, and environmental conditions.

Safety and Maintenance Considerations

Spread mooring systems offer enhanced safety through multiple anchor points, reducing the risk of vessel drift and providing better stability during adverse weather conditions. Single point mooring simplifies maintenance with fewer components exposed to wear, but requires rigorous inspection to prevent failure at the single connection point. You should evaluate the trade-offs between the distributed safety benefits of spread mooring and the maintenance efficiency of single point mooring to optimize operational reliability.

Conclusion: Choosing the Right Mooring System

Spread mooring systems offer enhanced stability and load distribution, making them ideal for larger vessels requiring multiple anchor points. Single point mooring (SPM) systems provide greater flexibility and quick rotation, suitable for tanker operations in deepwater environments. Selecting the right mooring system depends on vessel size, environmental conditions, and operational requirements to ensure safety, efficiency, and cost-effectiveness.

Spread mooring vs single point mooring Infographic

libmatt.com

libmatt.com