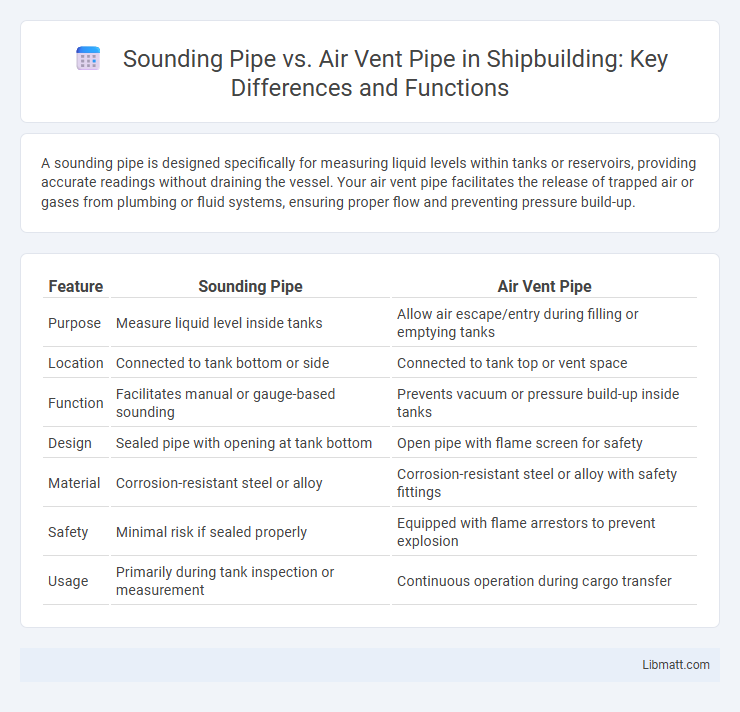

A sounding pipe is designed specifically for measuring liquid levels within tanks or reservoirs, providing accurate readings without draining the vessel. Your air vent pipe facilitates the release of trapped air or gases from plumbing or fluid systems, ensuring proper flow and preventing pressure build-up.

Table of Comparison

| Feature | Sounding Pipe | Air Vent Pipe |

|---|---|---|

| Purpose | Measure liquid level inside tanks | Allow air escape/entry during filling or emptying tanks |

| Location | Connected to tank bottom or side | Connected to tank top or vent space |

| Function | Facilitates manual or gauge-based sounding | Prevents vacuum or pressure build-up inside tanks |

| Design | Sealed pipe with opening at tank bottom | Open pipe with flame screen for safety |

| Material | Corrosion-resistant steel or alloy | Corrosion-resistant steel or alloy with safety fittings |

| Safety | Minimal risk if sealed properly | Equipped with flame arrestors to prevent explosion |

| Usage | Primarily during tank inspection or measurement | Continuous operation during cargo transfer |

Introduction to Sounding Pipes and Air Vent Pipes

Sounding pipes are vertical pipes installed on storage tanks to measure liquid levels by allowing a sounding line or gauge to be lowered into the liquid. Air vent pipes, on the other hand, facilitate the release or intake of air to prevent pressure build-up or vacuum formation within tanks or pipelines. Both pipes play essential roles in maintaining operational safety and accuracy in fluid management systems.

Key Functions of Sounding Pipes

Sounding pipes serve as access points for measuring liquid levels inside tanks, ensuring accurate monitoring of contents in vessels such as fuel or water tanks. Unlike air vent pipes that primarily allow gases to escape and prevent pressure buildup, sounding pipes provide a direct channel for inserting measuring devices or dipsticks. You can rely on sounding pipes to maintain safe and precise management of liquid storage in industrial and marine environments.

Primary Roles of Air Vent Pipes

Air vent pipes primarily serve to release trapped air from plumbing systems, preventing airlocks that can disrupt water flow and pressure. Unlike sounding pipes, which are used to measure liquid levels within tanks, air vent pipes ensure proper ventilation and maintain system efficiency by allowing air to escape safely. Your plumbing system relies on air vent pipes to maintain smooth operation and prevent issues like pipe corrosion or water damage caused by pressure imbalances.

Construction and Design Differences

Sounding pipes are designed primarily for measurement purposes, featuring a narrow diameter and open-top structure that allows for manual checking of liquid levels within tanks or reservoirs. Air vent pipes, constructed with wider diameters and protective vents, facilitate the release and intake of air to prevent pressure imbalances in plumbing or drainage systems. Understanding these construction and design differences helps ensure your system maintains proper functionality and safety.

Installation Locations on Ships

Sounding pipes are typically installed on cargo tanks or ballast tanks on ships to measure liquid levels directly by inserting a measuring device, while air vent pipes are positioned on tank tops or cargo hold covers to allow air to escape or enter, preventing pressure buildup or vacuum during filling and emptying. The placement of sounding pipes is crucial for accurate level measurement and safety during cargo operations, whereas air vent pipes are strategically located to ensure proper ventilation and prevent structural damage. Understanding the distinct installation locations helps optimize your ship's tank management and maintain operational safety.

Operational Procedures and Best Practices

Sounding pipes require regular inspection and maintenance to ensure accurate measurement of liquid levels in tanks, making it essential to prevent blockages and contamination. Air vent pipes should be installed with proper sizing and positioning to allow pressure equalization and prevent vacuum formation, thus maintaining system integrity. You must follow safety protocols and use appropriate protective gear during operational procedures to avoid accidents and maintain equipment longevity.

Maintenance Requirements for Each Pipe Type

Sounding pipes require regular inspection to ensure accurate fluid level readings and prevent blockages caused by debris or corrosion. Air vent pipes demand routine cleaning and checks to avoid airlocks and moisture buildup that could impair venting efficiency. Proper maintenance of your sounding and air vent pipes prolongs system reliability and prevents operational disruptions.

Safety Considerations: Sounding Pipes vs Air Vent Pipes

Sounding pipes provide a critical safety function by allowing accurate measurement of liquid levels in tanks, preventing overfilling and potential spills that could lead to hazardous conditions. Air vent pipes ensure safe operation by releasing trapped gases and maintaining proper atmospheric pressure within storage tanks, reducing the risk of pressure buildup and possible explosions. Proper installation and maintenance of both sounding pipes and air vent pipes are essential for safeguarding your facility and complying with industry safety regulations.

Regulatory Standards and Compliance

Sounding pipes and air vent pipes must adhere to specific regulatory standards such as API 14C and NFPA codes to ensure safe and compliant operation in industrial systems. Sounding pipes, designed for manual level measurement, require compliance with regulations governing pressure containment and hazardous area classification under OSHA and IEC standards. Air vent pipes, essential for pressure relief and ventilation, must meet standards for emissions control and safe venting, including EPA air quality regulations and ASME codes for pressure vessel safety.

Choosing Between Sounding Pipes and Air Vent Pipes

Choosing between sounding pipes and air vent pipes depends on their specific functions in fluid systems. Sounding pipes provide a direct means to measure liquid levels in tanks, allowing you to accurately monitor contents using a gauge or probe, whereas air vent pipes facilitate the release of trapped air to prevent pressure buildup and maintain system efficiency. Understanding your system's requirements for liquid level measurement versus air release is essential to selecting the appropriate pipe type.

Sounding pipe vs air vent pipe Infographic

libmatt.com

libmatt.com