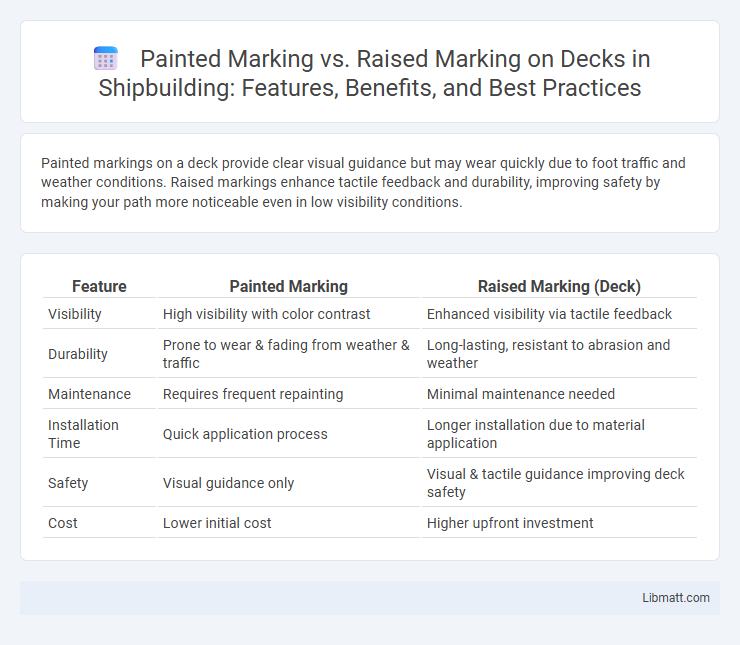

Painted markings on a deck provide clear visual guidance but may wear quickly due to foot traffic and weather conditions. Raised markings enhance tactile feedback and durability, improving safety by making your path more noticeable even in low visibility conditions.

Table of Comparison

| Feature | Painted Marking | Raised Marking (Deck) |

|---|---|---|

| Visibility | High visibility with color contrast | Enhanced visibility via tactile feedback |

| Durability | Prone to wear & fading from weather & traffic | Long-lasting, resistant to abrasion and weather |

| Maintenance | Requires frequent repainting | Minimal maintenance needed |

| Installation Time | Quick application process | Longer installation due to material application |

| Safety | Visual guidance only | Visual & tactile guidance improving deck safety |

| Cost | Lower initial cost | Higher upfront investment |

Introduction to Deck Markings

Deck markings serve as essential visual guides for aircraft pilots and ground crew, ensuring safe and efficient operations on airport runways and taxiways. Painted markings provide clear, cost-effective symbols and lines but can wear down quickly due to weather and traffic. Raised markings offer enhanced durability and tactile feedback, improving visibility in adverse conditions, which can significantly benefit your airport's operational safety and maintenance strategy.

Overview of Painted Markings

Painted markings on decks provide clear visual guidance using durable, high-contrast paint formulations designed to withstand harsh environmental conditions and heavy foot traffic. These markings offer cost-effective, easy-to-apply solutions that enhance safety by delineating walkways, hazard zones, and directional cues. Compared to raised markings, painted markings require more frequent maintenance but allow for quicker updates and customization on large surface areas.

Overview of Raised Markings

Raised markings on decks provide tactile and visual cues that enhance safety by improving traction and visibility, especially in wet or low-light conditions. Unlike painted markings, raised markings are three-dimensional and often made from durable materials like thermoplastic or rubber, offering greater longevity and resistance to wear. Your navigation and positioning benefit from these reliable markers that reduce the risk of slips and missteps on decks.

Durability Comparison: Painted vs Raised

Painted deck markings typically last between 6 months to 2 years depending on traffic and weather conditions, requiring frequent maintenance and repainting. Raised deck markings, often made from thermoplastic or epoxy materials combined with reflective elements, offer superior durability, lasting up to 5-7 years with minimal wear under heavy traffic. The enhanced longevity and visibility of raised markings significantly reduce maintenance costs and improve safety compared to painted alternatives.

Installation Process: Painted vs Raised Markings

The installation of painted deck markings involves applying specialized durable paint directly onto the surface, allowing for quick drying and immediate use, suitable for various traffic and safety indications. Raised deck markings require placing pre-fabricated thermoplastic or rubber materials onto the deck, often necessitating surface preparation, heating, and curing time for proper adhesion and durability under heavy traffic. Your choice between painted and raised markings will impact installation time, surface preparation needs, and long-term maintenance.

Cost Analysis: Initial and Maintenance Expenses

Painted markings on decks generally incur lower initial costs due to inexpensive materials and straightforward application processes, but they require frequent maintenance and repainting, driving up long-term expenses. Raised markings, such as thermoplastic or epoxy markers, involve higher upfront installation costs owing to durable materials and specialized equipment but benefit from extended lifespan and reduced maintenance frequency. Evaluating cost-effectiveness depends on traffic volume and environmental conditions, with raised markings favored in high-traffic or harsh environments for their durability despite higher initial investment.

Safety and Visibility Considerations

Painted markings provide clear visual cues on decks but can become slippery when wet, potentially compromising safety. Raised markings enhance traction and tactile feedback, improving footing and visibility in low-light or adverse weather conditions. Your choice should balance durability and environmental factors to ensure maximum safety and visibility.

Weather Resistance and Longevity

Painted markings typically offer less weather resistance and tend to fade or peel over time due to exposure to sun, rain, and temperature fluctuations. Raised markings, often made from durable materials like thermoplastic or rubber, provide superior longevity and maintain visibility even in harsh weather conditions. Your choice of deck markings should prioritize raised options for extended durability and consistent safety performance.

Application Suitability: When to Use Each Type

Painted markings are ideal for temporary or low-traffic deck surfaces due to their ease of application and cost-effectiveness, providing clear visibility on smooth surfaces. Raised markings, featuring tactile elements like studs or ribs, are best suited for high-traffic or safety-critical areas where durable, slip-resistant guidance is essential under various weather conditions. Choose raised markings for enhanced durability and tactile feedback, while painted markings serve well for quick installation and less demanding environments, ensuring Your deck's safety aligns with its usage requirements.

Conclusion: Choosing the Right Deck Marking

Selecting the right deck marking depends on factors like durability, visibility, and maintenance requirements. Painted markings offer cost-effective, easy-to-apply solutions with moderate wear resistance, while raised markings provide enhanced tactile feedback and superior slip resistance. Your choice should align with the specific safety needs and environmental conditions of the deck to ensure maximum effectiveness.

Painted marking vs raised marking (deck) Infographic

libmatt.com

libmatt.com