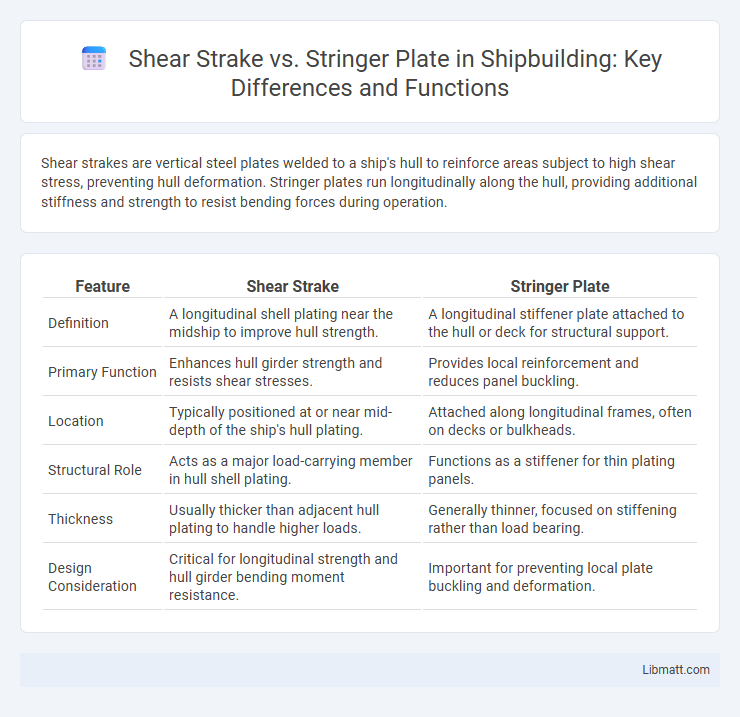

Shear strakes are vertical steel plates welded to a ship's hull to reinforce areas subject to high shear stress, preventing hull deformation. Stringer plates run longitudinally along the hull, providing additional stiffness and strength to resist bending forces during operation.

Table of Comparison

| Feature | Shear Strake | Stringer Plate |

|---|---|---|

| Definition | A longitudinal shell plating near the midship to improve hull strength. | A longitudinal stiffener plate attached to the hull or deck for structural support. |

| Primary Function | Enhances hull girder strength and resists shear stresses. | Provides local reinforcement and reduces panel buckling. |

| Location | Typically positioned at or near mid-depth of the ship's hull plating. | Attached along longitudinal frames, often on decks or bulkheads. |

| Structural Role | Acts as a major load-carrying member in hull shell plating. | Functions as a stiffener for thin plating panels. |

| Thickness | Usually thicker than adjacent hull plating to handle higher loads. | Generally thinner, focused on stiffening rather than load bearing. |

| Design Consideration | Critical for longitudinal strength and hull girder bending moment resistance. | Important for preventing local plate buckling and deformation. |

Introduction to Shear Strake and Stringer Plate

Shear strakes are structural steel plates welded along the length of ship hulls and bridges to enhance longitudinal strength and resist shear forces caused by bending. Stringer plates serve as stiffening elements attached to the web of girders or beams, increasing flexural rigidity and preventing buckling under load. Both components play critical roles in maintaining structural integrity in maritime and civil engineering applications by distributing stresses and improving load-bearing capacity.

Definition of Shear Strake

Shear strake is a structural steel plate welded to the hull of a ship or offshore platform to enhance longitudinal strength and resist shear forces from wave impacts and loading conditions. Unlike stringer plates, which primarily support bending moments along the length of the vessel, shear strakes provide additional reinforcement to prevent shear deformation and improve hull integrity. The careful placement of shear strakes contributes to the overall durability and safety of marine structures by distributing shear stresses effectively.

Definition of Stringer Plate

A stringer plate is a longitudinal structural element used in ships and steel structures to reinforce and stiffen the hull or framework. Unlike shear strakes, which primarily resist shear forces and prevent buckling along the hull, stringer plates provide continuous support along the length, improving the overall rigidity and strength of the structure. They are typically welded parallel to the keel line, enhancing the ship's resistance to bending stresses and contributing to hull integrity.

Location of Shear Strake and Stringer Plate in Ship Structure

Shear strakes are typically installed along the outer shell plating near the ship's bottom or sides to reinforce longitudinal strength and resist shear forces caused by hull bending. Stringer plates are positioned along the inner side shell plating or deck, acting as longitudinal stiffeners to enhance the structural integrity of bulkheads and frames. Your ship's design ensures shear strakes address transverse stresses while stringer plates support the hull's overall longitudinal rigidity.

Primary Function of Shear Strake

The primary function of a shear strake is to reinforce the hull or structural framework against shear forces, enhancing the overall rigidity and resistance to deformation under stress. Unlike a stringer plate, which primarily supports bending loads along the length of a structure, shear strakes provide critical lateral stiffness and distribute shear stresses more evenly. Optimizing your design with shear strakes ensures increased durability and stability in heavy load conditions.

Primary Function of Stringer Plate

The primary function of a stringer plate is to provide longitudinal reinforcement along a ship's hull, distributing stresses and enhancing structural integrity. Stringer plates support the framing by connecting the shell plating to the underlying framework, reducing deformation under load. You can rely on stringer plates to maintain the vessel's strength and durability during operation.

Material and Thickness Comparison

Shear strakes are typically constructed from thicker steel plates, ranging from 10 to 20 mm, designed to withstand high shear forces and provide stiffening in ship hull structures. Stringer plates, on the other hand, are usually made from thinner steel, often between 6 to 12 mm, serving primarily as longitudinal stiffeners to support bending loads. Your choice between shear strake and stringer plate depends on the specific structural requirements, where heavier gauge materials in shear strakes offer enhanced resistance to shear stresses compared to the lighter stringer plates.

Structural Significance: Shear Strake vs Stringer Plate

Shear strakes are essential structural components designed to enhance a ship's hull strength by resisting shear forces and preventing buckling in critical areas, particularly along the shell plating. Stringer plates serve to reinforce longitudinal strength by stiffening the hull and supporting bending stresses, distributed along the vessel's length. The integration of shear strakes primarily targets shear load management, while stringer plates optimize overall hull rigidity and bending resistance.

Common Issues and Maintenance Concerns

Shear strakes and stringer plates often face corrosion and fatigue cracks due to constant stress and exposure to harsh marine environments. Regular inspections for corrosion pitting, loose fasteners, and weld integrity are essential to maintain structural strength and prevent costly repairs. You should prioritize timely cleaning, protective coating applications, and prompt replacement of damaged components to ensure long-term durability and safety.

Conclusion: Choosing Between Shear Strake and Stringer Plate

Choosing between a shear strake and a stringer plate depends on the specific structural demands and load distribution requirements of the vessel or structure. Shear strakes are optimal for enhancing transverse strength and resisting shear forces along the hull, while stringer plates provide longitudinal reinforcement and improve bending resistance. Evaluating factors such as stress patterns, fabrication complexity, and maintenance considerations ensures the best choice for durability and performance.

Shear strake vs stringer plate Infographic

libmatt.com

libmatt.com