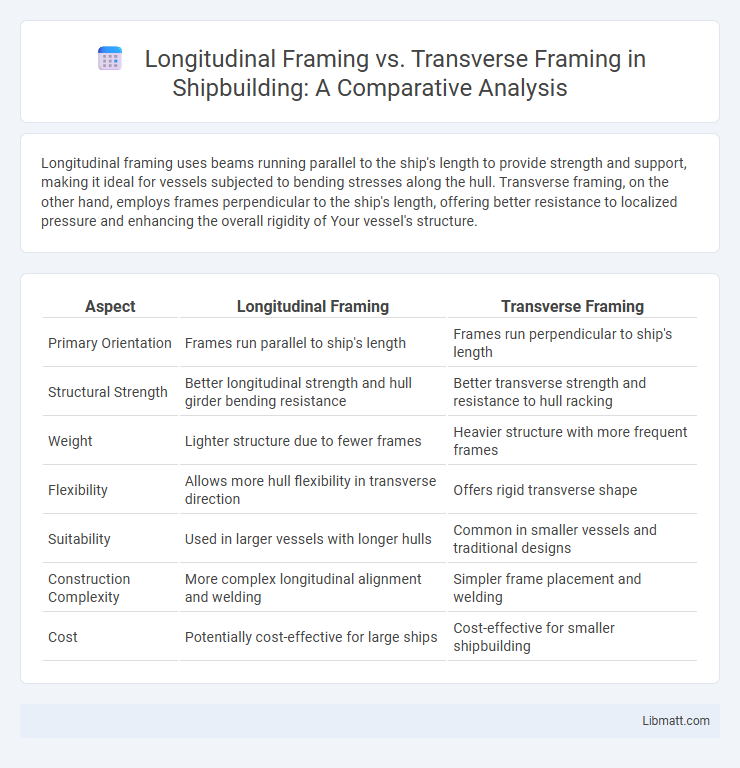

Longitudinal framing uses beams running parallel to the ship's length to provide strength and support, making it ideal for vessels subjected to bending stresses along the hull. Transverse framing, on the other hand, employs frames perpendicular to the ship's length, offering better resistance to localized pressure and enhancing the overall rigidity of Your vessel's structure.

Table of Comparison

| Aspect | Longitudinal Framing | Transverse Framing |

|---|---|---|

| Primary Orientation | Frames run parallel to ship's length | Frames run perpendicular to ship's length |

| Structural Strength | Better longitudinal strength and hull girder bending resistance | Better transverse strength and resistance to hull racking |

| Weight | Lighter structure due to fewer frames | Heavier structure with more frequent frames |

| Flexibility | Allows more hull flexibility in transverse direction | Offers rigid transverse shape |

| Suitability | Used in larger vessels with longer hulls | Common in smaller vessels and traditional designs |

| Construction Complexity | More complex longitudinal alignment and welding | Simpler frame placement and welding |

| Cost | Potentially cost-effective for large ships | Cost-effective for smaller shipbuilding |

Introduction to Framing Techniques in Construction

Longitudinal framing in construction involves aligning structural elements parallel to the building's length, providing enhanced stability for elongated structures. Transverse framing places components perpendicular to the length, optimizing load distribution across widths and offering resistance to lateral forces. Both techniques are fundamental in architectural design, influencing material efficiency and structural integrity based on building dimensions and functional requirements.

Defining Longitudinal Framing

Longitudinal framing is a structural approach where the main load-bearing elements run parallel to the length of a vessel or building, providing continuous support along its long axis. This method enhances rigidity and resistance to bending stresses, especially useful in large, elongated structures such as ships or aircraft fuselages. Your choice of longitudinal framing impacts the overall strength and durability by distributing forces efficiently along the structure's length.

Understanding Transverse Framing

Transverse framing consists of closely spaced crosswise members, such as floor joists, roof rafters, and wall studs, that support the structure by distributing loads perpendicular to the building's length. This method enhances structural stability by resisting lateral forces and preventing bending, making it ideal for residential and light commercial construction. Understanding transverse framing allows you to effectively design or assess buildings where load distribution and rigidity across shorter spans are critical for safety and performance.

Key Differences Between Longitudinal and Transverse Framing

Longitudinal framing features structural members running parallel to the length of a ship, offering greater strength for handling bending stresses over the hull's length, while transverse framing consists of frames that run perpendicular to the vessel's length, providing enhanced resistance to localized pressure and external forces. Longitudinal framing optimizes your vessel's ability to withstand hogging and sagging along the longitudinal axis, whereas transverse framing is more effective in maintaining the hull's shape against water pressure and impacts. Selecting the appropriate framing system depends on factors such as ship size, purpose, and the balance between overall hull strength and localized support needs.

Structural Advantages of Longitudinal Framing

Longitudinal framing offers superior structural advantages by efficiently distributing loads along the length of the vessel or structure, enhancing overall strength and rigidity. This method reduces stress concentrations through continuous longitudinal members, improving resistance to bending and torsional forces. For your project, choosing longitudinal framing can result in a lighter, more robust construction capable of withstanding dynamic marine or architectural stresses.

Benefits of Transverse Framing in Modern Architecture

Transverse framing enhances structural stability by efficiently distributing loads across shorter spans, reducing material use and construction costs. This method promotes faster assembly and greater flexibility in interior space design, accommodating modern architectural demands for open, adaptable layouts. Improved resistance to lateral forces makes transverse framing ideal for high-rise buildings and seismic zones, ensuring safety and durability.

Applications of Longitudinal vs Transverse Framing

Longitudinal framing, characterized by structural members aligned with the length of a vessel or building, is primarily applied in shipbuilding and aircraft fuselage design where continuous strength and resistance to bending are critical. Transverse framing, featuring crosswise supports, is widely used in bridge construction, automotive chassis, and building floors to provide rigidity and distribute loads evenly. Both framing methods optimize structural integrity, with longitudinal framing excelling in long-span applications and transverse framing preferred for localized load resistance.

Factors Influencing the Choice of Framing Orientation

The choice between longitudinal framing and transverse framing depends on factors such as load distribution, structural strength, and vessel size. Longitudinal framing is often preferred for large ships requiring enhanced resistance to bending moments, while transverse framing is suitable for smaller vessels with greater emphasis on local strength and ease of construction. Your decision should consider the vessel's operational demands, material efficiency, and maintenance requirements.

Case Studies: Successful Implementation of Each Method

Case studies reveal longitudinal framing was successfully implemented in high-rise construction projects like the Burj Khalifa, providing exceptional vertical load distribution and rigidity for tall structures. Transverse framing found success in residential buildings such as the Crystal Bridges Museum, optimizing lateral stability and simplifying assembly with cross beams enhancing seismic resistance. Understanding the strengths of each method allows your construction project to benefit from tailored structural integrity and cost efficiency.

Future Trends in Structural Framing Systems

Future trends in structural framing systems show a shift towards hybrid designs that combine longitudinal and transverse framing to optimize load distribution and enhance seismic resilience. Innovations in materials, such as high-strength composites and advanced steel alloys, enable lighter frameworks with improved durability, supporting more flexible architectural layouts. Digital modeling and automated construction techniques are increasingly integrated to precisely tailor framing configurations, minimizing waste and accelerating project timelines in both longitudinal and transverse framing applications.

Longitudinal framing vs transverse framing Infographic

libmatt.com

libmatt.com