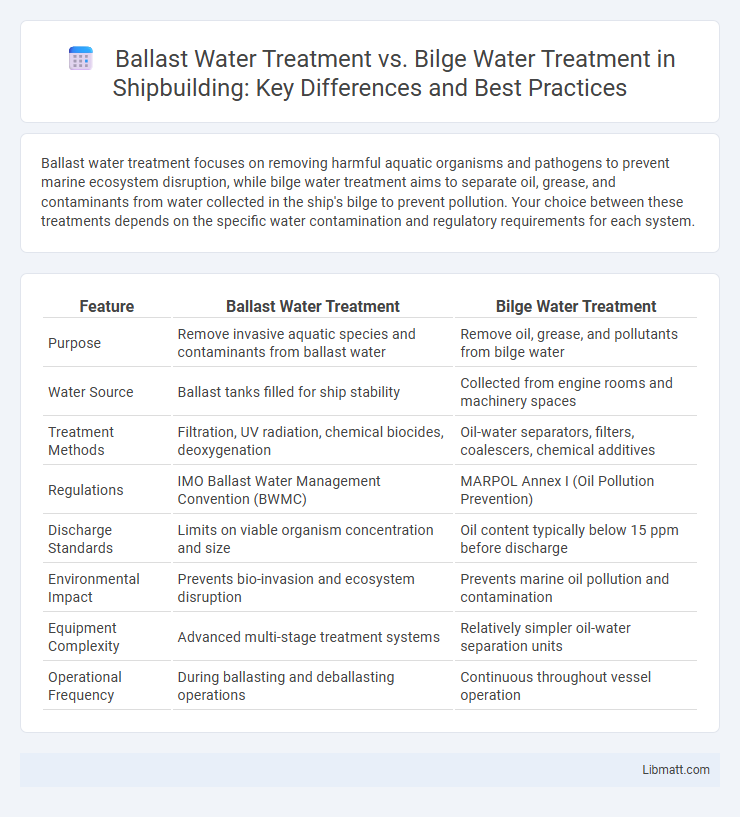

Ballast water treatment focuses on removing harmful aquatic organisms and pathogens to prevent marine ecosystem disruption, while bilge water treatment aims to separate oil, grease, and contaminants from water collected in the ship's bilge to prevent pollution. Your choice between these treatments depends on the specific water contamination and regulatory requirements for each system.

Table of Comparison

| Feature | Ballast Water Treatment | Bilge Water Treatment |

|---|---|---|

| Purpose | Remove invasive aquatic species and contaminants from ballast water | Remove oil, grease, and pollutants from bilge water |

| Water Source | Ballast tanks filled for ship stability | Collected from engine rooms and machinery spaces |

| Treatment Methods | Filtration, UV radiation, chemical biocides, deoxygenation | Oil-water separators, filters, coalescers, chemical additives |

| Regulations | IMO Ballast Water Management Convention (BWMC) | MARPOL Annex I (Oil Pollution Prevention) |

| Discharge Standards | Limits on viable organism concentration and size | Oil content typically below 15 ppm before discharge |

| Environmental Impact | Prevents bio-invasion and ecosystem disruption | Prevents marine oil pollution and contamination |

| Equipment Complexity | Advanced multi-stage treatment systems | Relatively simpler oil-water separation units |

| Operational Frequency | During ballasting and deballasting operations | Continuous throughout vessel operation |

Introduction to Maritime Water Management

Ballast water treatment focuses on removing invasive aquatic species and pathogens to protect marine ecosystems, using advanced filtration and disinfection systems compliant with IMO regulations. Bilge water treatment targets the removal of oil, grease, and contaminants from engine room water before discharge, ensuring adherence to MARPOL Annex I standards. Your vessel's environmental compliance depends on selecting appropriate technologies tailored to these distinct maritime water management challenges.

Understanding Ballast Water Treatment

Ballast water treatment involves the removal or neutralization of aquatic organisms and pathogens in water taken on board ships to maintain stability, preventing environmental contamination and invasive species spread. Unlike bilge water treatment, which focuses on separating oil and contaminants from water collected in ship engine rooms, ballast water treatment employs filtration, UV irradiation, or chemical disinfection to meet international maritime regulations. Your vessel's compliance with the International Maritime Organization's Ballast Water Management Convention ensures protection of marine ecosystems and avoids heavy penalties.

Overview of Bilge Water Treatment

Bilge water treatment focuses on removing oil, grease, and other contaminants from the oily water collected in the lower parts of a ship's hull, ensuring compliance with MARPOL regulations. Advanced filtration, centrifugation, and chemical treatment systems are commonly used to separate pollutants and allow safe discharge or reuse. Your vessel's efficient bilge water treatment safeguards marine environments from harmful pollution and supports sustainable shipping practices.

Key Differences Between Ballast and Bilge Water

Ballast water treatment primarily targets the removal of invasive aquatic species and sediment to comply with the International Maritime Organization (IMO) Ballast Water Management Convention regulations. Bilge water treatment focuses on separating oil, grease, and other contaminants from water collected in the ship's bilge, adhering to MARPOL Annex I requirements for oil discharge limits. The key difference lies in their treatment objectives: ballast water aims to prevent ecological harm from transferred marine organisms, while bilge water treatment ensures oil pollution prevention from operational ship waste.

Regulatory Frameworks and Compliance Standards

Ballast water treatment and bilge water treatment are governed by distinct regulatory frameworks tailored to prevent marine pollution and protect ecosystems. Ballast water treatment must comply with the International Maritime Organization's (IMO) Ballast Water Management Convention (BWMC), enforcing standards for the discharge of invasive aquatic species through approved treatment technologies. Bilge water treatment aligns with regulations such as MARPOL Annex I, requiring ship operators to manage oil pollution by maintaining oil content below 15 ppm before discharge, ensuring Your vessels meet international environmental compliance standards.

Common Technologies for Ballast Water Treatment

Common technologies for ballast water treatment include filtration, ultraviolet (UV) irradiation, and chemical biocides, designed to remove or neutralize invasive aquatic organisms and pathogens. Advanced oxidation processes and electrochlorination are also frequently employed to ensure compliance with international regulations such as the IMO Ballast Water Management Convention. You can optimize your vessel's environmental safety by selecting a ballast water treatment system that integrates these proven technologies for effective and sustainable maritime operations.

Effective Methods for Bilge Water Treatment

Effective methods for bilge water treatment prioritize the removal of oil, sediments, and contaminants to comply with MARPOL Annex I regulations. Key technologies include oily water separators (OWS) that use gravity separation, coalescing filters, and centrifuges to efficiently extract hydrocarbons and suspended solids. Advanced systems may incorporate bioremediation and chemical dosing to further reduce pollutant levels before discharge, ensuring environmental safety and regulatory compliance.

Environmental Impact: Ballast vs. Bilge Water

Ballast water treatment primarily addresses the prevention of invasive aquatic species transfer and the reduction of pathogens in marine ecosystems, significantly protecting biodiversity and water quality. Bilge water treatment targets the removal of oil, grease, and hazardous substances before discharge, minimizing marine pollution and threats to wildlife from toxic contaminants. Your choice between these treatments influences the environmental impact on marine ecosystems, with ballast water systems focusing on biological health and bilge water systems on chemical pollution control.

Challenges in Implementing Treatment Solutions

Ballast water treatment faces challenges such as the complexity of removing diverse invasive aquatic species and meeting stringent international regulations like the IMO Ballast Water Management Convention. Bilge water treatment struggles with separating oil and other contaminants efficiently due to variable water composition and limited onboard space for advanced treatment systems. Optimizing Your ship's compliance requires balancing equipment capabilities with operational constraints while ensuring environmental protection.

Future Trends in Shipboard Water Treatment Systems

Advanced shipboard water treatment systems are evolving with a focus on enhancing sustainability and compliance with stricter environmental regulations, particularly in ballast water and bilge water management. Innovations such as electrochlorination, ultraviolet irradiation, and real-time monitoring technologies are setting the future standards for effective disinfection and pollutant removal. Your vessel's upgrade to these smart treatment solutions will ensure operational efficiency while minimizing ecological impact.

Ballast water treatment vs bilge water treatment Infographic

libmatt.com

libmatt.com