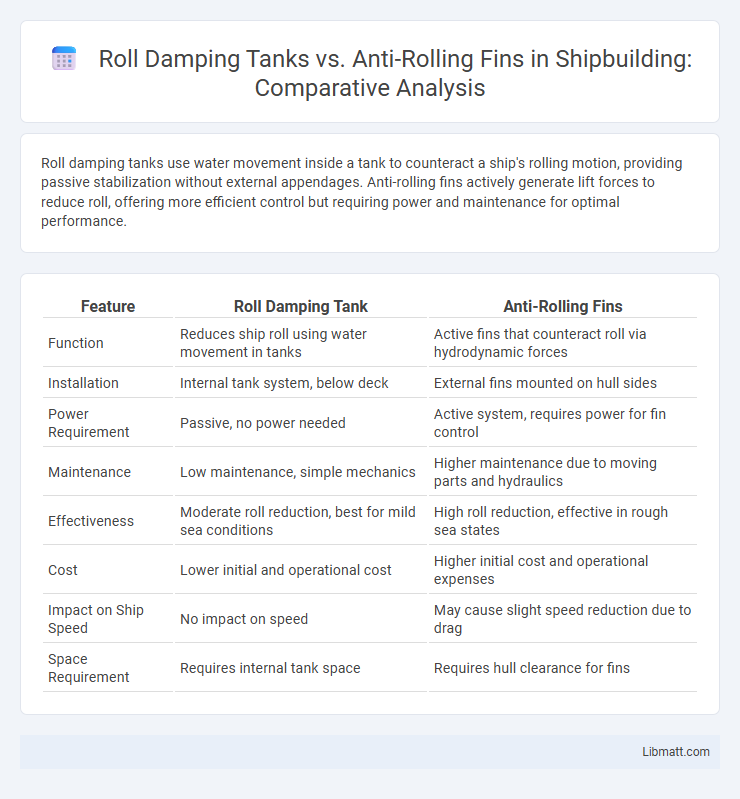

Roll damping tanks use water movement inside a tank to counteract a ship's rolling motion, providing passive stabilization without external appendages. Anti-rolling fins actively generate lift forces to reduce roll, offering more efficient control but requiring power and maintenance for optimal performance.

Table of Comparison

| Feature | Roll Damping Tank | Anti-Rolling Fins |

|---|---|---|

| Function | Reduces ship roll using water movement in tanks | Active fins that counteract roll via hydrodynamic forces |

| Installation | Internal tank system, below deck | External fins mounted on hull sides |

| Power Requirement | Passive, no power needed | Active system, requires power for fin control |

| Maintenance | Low maintenance, simple mechanics | Higher maintenance due to moving parts and hydraulics |

| Effectiveness | Moderate roll reduction, best for mild sea conditions | High roll reduction, effective in rough sea states |

| Cost | Lower initial and operational cost | Higher initial cost and operational expenses |

| Impact on Ship Speed | No impact on speed | May cause slight speed reduction due to drag |

| Space Requirement | Requires internal tank space | Requires hull clearance for fins |

Introduction to Ship Roll Stabilization

Ship roll stabilization techniques include roll damping tanks and anti-rolling fins to reduce the vessel's rolling motion in rough seas. Roll damping tanks use water movement within the tank to counteract roll, relying on passive energy dissipation for stabilization. Anti-rolling fins are active hydrodynamic devices extending from the hull, generating lift forces to counteract roll motions dynamically and improve onboard comfort and safety.

Overview of Roll Damping Tanks

Roll damping tanks are specially designed compartments within a ship's hull filled with water or another fluid to reduce the vessel's rolling motion by using the fluid's inertia to counteract the roll. Unlike anti-rolling fins, which are external appendages actively controlled to stabilize the ship, roll damping tanks leverage passive hydrodynamic effects and require no energy input or mechanical adjustments. Your choice of roll damping tanks enhances stability through a simple, maintenance-friendly solution that improves onboard comfort and safety during rough sea conditions.

Working Principles of Anti-Rolling Fins

Anti-rolling fins operate by generating lift forces perpendicular to the flow of water as the ship moves, counteracting the rolling motion induced by waves. These fins are controlled by hydraulic or electronic stabilizers that adjust their angle of attack dynamically to maximize roll reduction. The rapid and precise adjustments of the fins' position create torque to oppose roll, enhancing vessel stability and passenger comfort without significantly impacting forward speed.

Comparative Effectiveness in Reducing Roll

Roll damping tanks utilize water movement within a compartment to counteract ship roll by shifting the liquid's momentum opposite to the vessel's motion, providing passive stabilization with minimal mechanical complexity. Anti-rolling fins actively generate lift via hydraulically controlled fins extending from the hull, producing immediate and adjustable counterforces that effectively reduce roll amplitude, especially at higher speeds. While roll damping tanks offer cost-effective and low-maintenance solutions suitable for moderate sea conditions, anti-rolling fins deliver superior roll reduction performance in dynamic environments, albeit with increased installation and operational complexity.

Installation and Maintenance Requirements

Roll damping tanks require significant hull space and must be carefully integrated during new builds or major retrofits, with periodic inspections to manage fluid levels and prevent corrosion. Anti-rolling fins involve complex external installations requiring precise alignment and regular maintenance of mechanical components, including bearings and actuators, to ensure optimal performance. Your choice depends on the ship's design constraints and maintenance capabilities, as tanks generally demand less frequent but more intensive upkeep compared to the continuous operational checks needed for fins.

Impact on Ship Performance and Efficiency

Roll damping tanks reduce ship roll by using fluid movement within the tank, improving stability with minimal additional drag, thereby enhancing fuel efficiency and overall performance. Anti-rolling fins generate lift forces to counteract roll, offering rapid stabilization but often increasing hydrodynamic resistance, which can lead to higher fuel consumption. The choice between roll damping tanks and anti-rolling fins depends on balancing roll reduction effectiveness against impacts on propulsion efficiency and operational costs.

Space and Weight Considerations

Roll damping tanks require significant internal space and add considerable weight due to large volumes of liquid needed to counteract vessel roll, impacting overall ship stability and design constraints. Anti-rolling fins, installed externally on the hull, save internal space but increase hydrodynamic resistance and require mechanical systems that add weight primarily outside the vessel. Your choice depends on balancing available internal volume against added external drag and complexity in weight distribution.

Suitability for Different Vessel Types

Roll damping tanks are highly suitable for vessels with limited external appendage space, such as yachts and small fishing boats, offering internal stabilization without affecting the hull's hydrodynamic profile. Anti-rolling fins excel on larger commercial ships and offshore vessels, providing active stabilization through adjustable fins that counteract roll motions effectively at various speeds. Your choice depends on vessel type, size, operational profile, and space availability, with roll damping tanks ideal for compact boats and fins preferred for larger, high-speed ships.

Cost Analysis: Roll Damping Tank vs Anti-Rolling Fins

Roll damping tanks generally incur lower upfront costs compared to anti-rolling fins due to simpler installation and maintenance requirements. Anti-rolling fins, while more expensive initially, offer enhanced performance and fuel efficiency that can reduce long-term operational expenses. Your choice depends on budget constraints and desired effectiveness in roll stabilization.

Future Trends in Ship Roll Stabilization Technologies

Future trends in ship roll stabilization technologies emphasize enhanced efficiency and automation through integration of roll damping tanks and advanced anti-rolling fins equipped with real-time sensor feedback and AI-driven control systems. Innovations in active fluid management within roll damping tanks aim to optimize energy absorption while reducing maintenance compared to mechanical fins. Hybrid stabilization solutions combining the passive damping of tanks with the dynamic responsiveness of anti-rolling fins are expected to shape next-generation maritime vessel stability and fuel efficiency standards.

Roll damping tank vs anti-rolling fins Infographic

libmatt.com

libmatt.com