Marine elevators are specially designed to withstand harsh maritime environments, featuring corrosion-resistant materials and waterproof components for durability on ships or offshore platforms. Industrial elevators focus on heavy-duty lifting capacity and rugged construction to handle materials and personnel in factories, warehouses, and construction sites, ensuring efficiency and safety in demanding industrial settings.

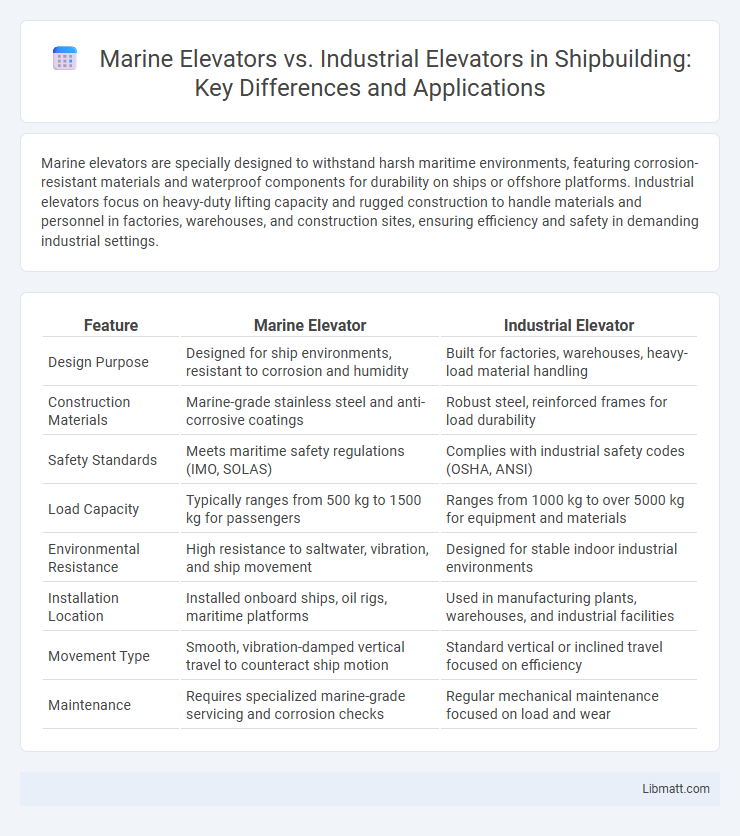

Table of Comparison

| Feature | Marine Elevator | Industrial Elevator |

|---|---|---|

| Design Purpose | Designed for ship environments, resistant to corrosion and humidity | Built for factories, warehouses, heavy-load material handling |

| Construction Materials | Marine-grade stainless steel and anti-corrosive coatings | Robust steel, reinforced frames for load durability |

| Safety Standards | Meets maritime safety regulations (IMO, SOLAS) | Complies with industrial safety codes (OSHA, ANSI) |

| Load Capacity | Typically ranges from 500 kg to 1500 kg for passengers | Ranges from 1000 kg to over 5000 kg for equipment and materials |

| Environmental Resistance | High resistance to saltwater, vibration, and ship movement | Designed for stable indoor industrial environments |

| Installation Location | Installed onboard ships, oil rigs, maritime platforms | Used in manufacturing plants, warehouses, and industrial facilities |

| Movement Type | Smooth, vibration-damped vertical travel to counteract ship motion | Standard vertical or inclined travel focused on efficiency |

| Maintenance | Requires specialized marine-grade servicing and corrosion checks | Regular mechanical maintenance focused on load and wear |

Introduction to Marine and Industrial Elevators

Marine elevators are specifically designed for use on ships and offshore platforms, featuring corrosion-resistant materials and advanced safety systems to withstand harsh marine environments. Industrial elevators serve factories, warehouses, and manufacturing facilities, optimized for heavy loads, durability, and efficient vertical transportation of goods and personnel. Both types prioritize safety and reliability but are engineered to meet the distinct operational challenges of their respective settings.

Key Differences Between Marine and Industrial Elevators

Marine elevators are specifically designed to withstand harsh marine environments, featuring corrosion-resistant materials and sealed components to prevent saltwater damage, whereas industrial elevators prioritize heavy-load capacity and durability under continuous operation in factories or warehouses. Marine elevators often incorporate advanced vibration and motion stabilization systems to accommodate ship movement, while industrial elevators focus on speed and efficiency for frequent vertical transportation of goods and personnel. The safety standards for marine elevators align with maritime regulations, contrasting with stringent industrial safety codes tailored for land-based, industrial settings.

Structural Design Considerations

Marine elevators feature corrosion-resistant materials and reinforced sealing to withstand harsh saltwater exposure and constant vibrations, ensuring longevity and safety on vessels. Industrial elevators prioritize heavy-duty steel frameworks and robust suspension systems designed to handle substantial loads, frequent use, and exposure to dust or chemicals in factory environments. Your choice should factor in these structural design differences to match operational demands and environmental conditions accurately.

Environmental Challenges and Requirements

Marine elevators are specifically engineered to withstand harsh maritime environments, featuring corrosion-resistant materials and sealed systems to combat saltwater exposure, humidity, and extreme weather conditions. Industrial elevators prioritize robustness and heavy-duty performance, designed to handle dust, debris, and fluctuating temperatures commonly found in manufacturing plants or warehouses. Compliance with stringent safety standards and environmental regulations is critical for both types, ensuring operational reliability and longevity in their respective challenging environments.

Safety Standards and Regulations

Marine elevators must comply with stringent maritime safety standards such as SOLAS (Safety of Life at Sea) and IMO (International Maritime Organization) regulations, ensuring resilience against harsh marine environments and emergency scenarios. Industrial elevators adhere to OSHA (Occupational Safety and Health Administration) guidelines and ASME A17.1 codes, focusing on workplace safety, load capacities, and operational efficiency. Understanding the specific regulatory requirements for your elevator type is crucial for maintaining compliance and ensuring user safety.

Load Capacity and Performance

Marine elevators are engineered to withstand harsh sea conditions while offering moderate load capacities typically ranging from 1,000 to 3,000 lbs, ensuring reliable performance under constant motion and corrosion exposure. Industrial elevators prioritize high load capacity, often exceeding 10,000 lbs, designed to handle heavy machinery and bulk materials efficiently in fixed, controlled environments. Your choice depends on whether you require marine-grade durability and moderate loads or robust performance for substantial weight in industrial settings.

Installation and Maintenance Procedures

Marine elevators require corrosion-resistant materials and specialized sealing techniques during installation to withstand harsh sea environments, while industrial elevators prioritize heavy-duty components to support frequent use and heavy loads. Maintenance for marine elevators involves routine checks for saltwater damage, lubrication of moving parts with marine-grade oils, and inspections of electrical systems for moisture ingress. Industrial elevators focus maintenance efforts on structural integrity, load-bearing components, and regular calibration of safety mechanisms to ensure consistent performance under heavy operational demands.

Energy Efficiency and Power Systems

Marine elevators utilize advanced power systems designed to withstand harsh maritime environments, often incorporating energy-efficient variable frequency drives (VFDs) to optimize power consumption and reduce operational costs. In contrast, industrial elevators typically rely on robust electric or hydraulic power systems tailored for heavy-duty use, where energy efficiency is enhanced through regenerative drives that capture and reuse energy during braking. Your choice between marine and industrial elevators should consider the specific energy profiles and power system resilience required for your operational context.

Cost Factors and Budget Considerations

Marine elevators typically involve higher cost factors due to specialized corrosion-resistant materials and stringent safety standards required for harsh marine environments. Industrial elevators, while generally less expensive, prioritize load capacity and durability, which can influence initial investment and maintenance budgets based on operational demands. Budget considerations for marine elevators must account for long-term resistance to saltwater exposure, whereas industrial elevators emphasize efficiency and adaptability within factory or warehouse settings.

Choosing the Right Elevator Type for Your Application

Marine elevators are specifically designed to withstand harsh maritime environments, featuring corrosion-resistant materials and sealed components to ensure durability and safety on ships or offshore platforms. Industrial elevators prioritize heavy load capacities, robust construction, and adaptability to varied industrial settings such as factories or warehouses, enabling efficient material and personnel transport. Selecting the right elevator involves evaluating environmental conditions, load requirements, and compliance with industry-specific safety standards to ensure optimal performance and longevity.

Marine elevator vs industrial elevator Infographic

libmatt.com

libmatt.com