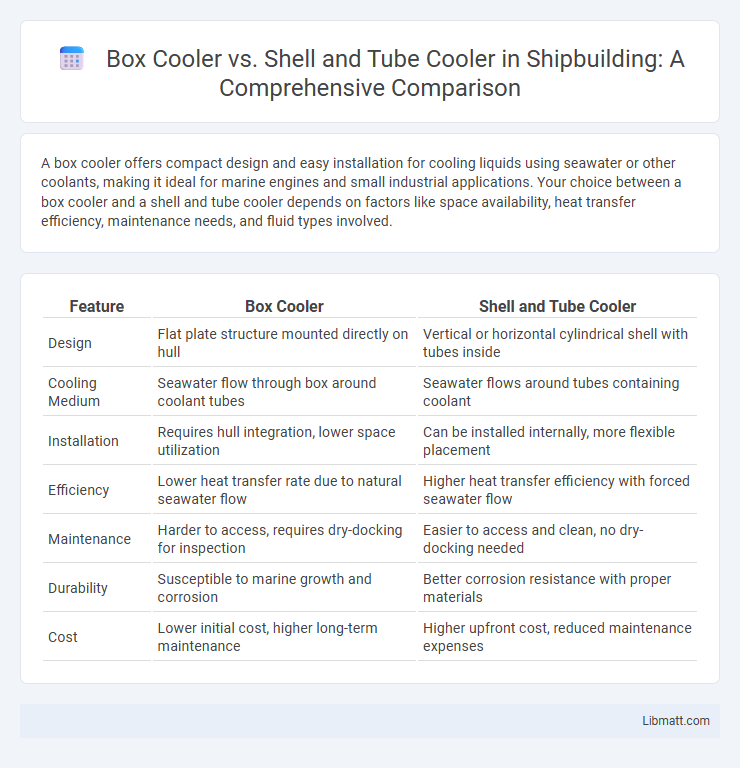

A box cooler offers compact design and easy installation for cooling liquids using seawater or other coolants, making it ideal for marine engines and small industrial applications. Your choice between a box cooler and a shell and tube cooler depends on factors like space availability, heat transfer efficiency, maintenance needs, and fluid types involved.

Table of Comparison

| Feature | Box Cooler | Shell and Tube Cooler |

|---|---|---|

| Design | Flat plate structure mounted directly on hull | Vertical or horizontal cylindrical shell with tubes inside |

| Cooling Medium | Seawater flow through box around coolant tubes | Seawater flows around tubes containing coolant |

| Installation | Requires hull integration, lower space utilization | Can be installed internally, more flexible placement |

| Efficiency | Lower heat transfer rate due to natural seawater flow | Higher heat transfer efficiency with forced seawater flow |

| Maintenance | Harder to access, requires dry-docking for inspection | Easier to access and clean, no dry-docking needed |

| Durability | Susceptible to marine growth and corrosion | Better corrosion resistance with proper materials |

| Cost | Lower initial cost, higher long-term maintenance | Higher upfront cost, reduced maintenance expenses |

Introduction to Marine Cooling Systems

Marine cooling systems are essential for maintaining optimal engine temperatures and preventing overheating in vessels. Box coolers integrate directly into the hull, offering efficient heat exchange through seawater circulation, while shell and tube coolers use a closed-loop system with coolant flowing through tubes surrounded by seawater. Understanding the differences in design and operation helps you select the most suitable marine cooling system for reliable engine performance and longevity.

Overview of Box Coolers

Box coolers feature a compact design where cooling water flows through a box-shaped structure around the tubes carrying the hot fluid, enhancing heat exchange efficiency in confined spaces. Unlike shell and tube coolers, box coolers provide a more integrated cooling solution suitable for marine and industrial applications with limited space. Your choice of a box cooler ensures efficient thermal management while minimizing installation complexity and spatial requirements.

Overview of Shell and Tube Coolers

Shell and tube coolers feature a robust design with a series of tubes enclosed within a cylindrical shell, enabling efficient heat transfer between fluids. Their high heat exchange capacity and durability make them suitable for heavy-duty industrial applications, including power plants and chemical processing. These coolers excel in handling high-pressure fluids and offer ease of maintenance due to removable tube bundles.

Key Differences Between Box and Shell & Tube Coolers

Box coolers feature internal baffles directing fluid flow through a compact, box-shaped housing, providing efficient heat exchange in limited spaces. Shell and tube coolers consist of a cylindrical shell containing multiple tubes, offering high heat transfer efficiency and easy maintenance due to their modular design. Understanding these key differences helps you select the appropriate cooler based on space constraints, maintenance preferences, and heat transfer requirements.

Efficiency and Performance Comparison

Box coolers provide enhanced efficiency in cooling seawater by maximizing surface area contact and minimizing pressure drop, making them ideal for marine engines with space constraints. Shell and tube coolers deliver superior thermal performance through multiple tube passes and robust construction, allowing higher heat transfer rates and greater durability under high-pressure conditions. The choice depends on specific operational requirements, with box coolers favoring compact design and shell and tube coolers excelling in heavy-duty, high-efficiency applications.

Installation Requirements and Space Considerations

Box coolers require simpler installation with fewer components, making them ideal for confined spaces and direct wall mounting. Shell and tube coolers demand more space due to their cylindrical design and piping complexity, often necessitating dedicated mounting structures. The compact form of box coolers benefits applications with limited installation areas, whereas shell and tube coolers suit larger setups with ample room for maintenance access.

Maintenance and Durability Analysis

Box coolers feature fewer moving parts and a simplified design, resulting in lower maintenance requirements and longer operational intervals compared to shell and tube coolers. Shell and tube coolers, while effective in heat transfer, demand frequent inspections and cleaning due to potential fouling and tube corrosion, impacting durability over time. Material selection and operating conditions heavily influence the lifespan of both cooling systems, with box coolers generally offering enhanced corrosion resistance and reduced mechanical wear.

Cost Implications and Lifecycle Value

Box coolers typically offer lower initial costs due to simpler construction and ease of installation, making them attractive for applications with budget constraints. Shell and tube coolers, while more expensive upfront, provide superior durability and maintenance flexibility, enhancing long-term lifecycle value in demanding industrial environments. Evaluating total cost of ownership should consider factors like operational efficiency, maintenance intervals, and expected service life specific to each cooler type.

Application Suitability and Industry Usage

Box coolers are ideal for heavy-duty applications involving crude oil transport and offshore platforms due to their robust design and resistance to fouling, making them widely used in the oil and gas industry. Shell and tube coolers excel in power plants and chemical processing facilities, offering high thermal efficiency and easy maintenance for handling corrosive fluids and high-pressure conditions. Understanding your operational environment helps determine which cooler aligns with your industry's performance requirements and maintenance capabilities.

Conclusion: Choosing the Right Cooler for Your Needs

Selecting the right cooler depends on your specific cooling requirements, space constraints, and maintenance preferences. Box coolers offer compact design and ease of cleaning, making them ideal for smaller installations or applications needing straightforward upkeep. Shell and tube coolers provide higher heat transfer efficiency and durability for larger systems or demanding industrial processes, ensuring optimal performance in heavy-duty environments.

Box cooler vs shell and tube cooler Infographic

libmatt.com

libmatt.com