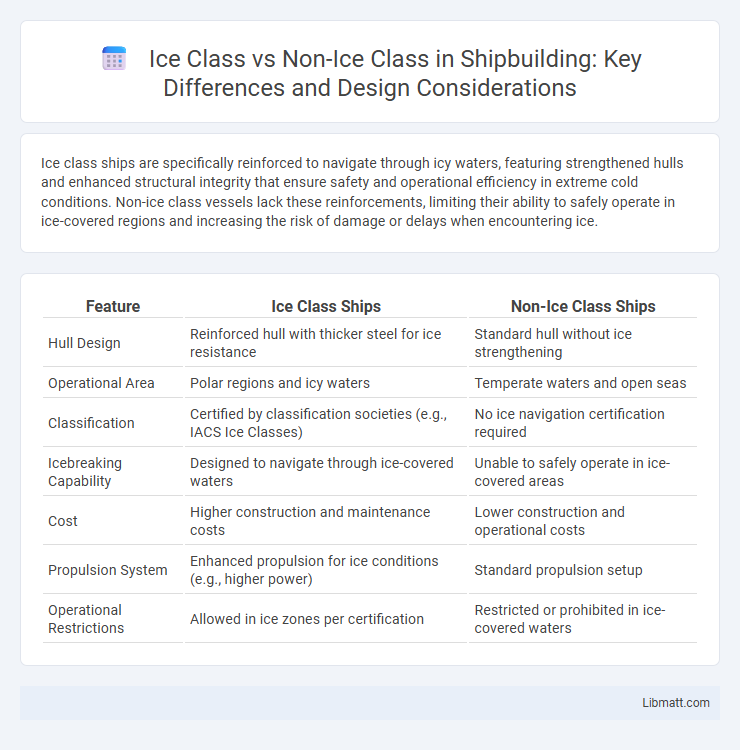

Ice class ships are specifically reinforced to navigate through icy waters, featuring strengthened hulls and enhanced structural integrity that ensure safety and operational efficiency in extreme cold conditions. Non-ice class vessels lack these reinforcements, limiting their ability to safely operate in ice-covered regions and increasing the risk of damage or delays when encountering ice.

Table of Comparison

| Feature | Ice Class Ships | Non-Ice Class Ships |

|---|---|---|

| Hull Design | Reinforced hull with thicker steel for ice resistance | Standard hull without ice strengthening |

| Operational Area | Polar regions and icy waters | Temperate waters and open seas |

| Classification | Certified by classification societies (e.g., IACS Ice Classes) | No ice navigation certification required |

| Icebreaking Capability | Designed to navigate through ice-covered waters | Unable to safely operate in ice-covered areas |

| Cost | Higher construction and maintenance costs | Lower construction and operational costs |

| Propulsion System | Enhanced propulsion for ice conditions (e.g., higher power) | Standard propulsion setup |

| Operational Restrictions | Allowed in ice zones per certification | Restricted or prohibited in ice-covered waters |

Understanding Ice Class and Non-Ice Class Vessels

Ice class vessels are specifically reinforced ships designed to navigate through ice-covered waters, featuring strengthened hulls and engines that meet regulatory ice class standards set by organizations like the International Association of Classification Societies (IACS). Non-ice class vessels lack these structural enhancements, making them unsuitable for operation in icy conditions due to the risk of hull damage or entrapment. Understanding these differences is crucial for selecting the right vessel for your maritime operations in polar or subpolar regions, ensuring safety and compliance with international regulations.

Key Design Differences Between Ice Class and Non-Ice Class Ships

Ice class ships feature reinforced hulls with thicker steel plating and strengthened frames designed to withstand impacts with ice, while non-ice class vessels have standard hull structures suited for open water conditions. Ice class vessels incorporate specialized bow shapes and more powerful engines to navigate icy waters efficiently, differing significantly from non-ice class ships built for fuel economy and speed in ice-free environments. Your choice between ice class and non-ice class ships should consider operational requirements and the severity of ice conditions encountered.

Ice Class Standards: Classification Societies and Requirements

Ice class standards are defined by classification societies such as Lloyd's Register, DNV, and the International Association of Classification Societies (IACS), each setting specific structural and machinery requirements for vessels operating in ice-covered waters. These standards include reinforced hulls, enhanced engine power, and specialized materials to withstand ice pressures, with varying levels like Ice Class 1A, 1B, or 1C indicating different degrees of ice capability. Non-ice class vessels lack these reinforcements and are restricted to open water operations, making compliance with ice class standards essential for safe navigation in polar and icy maritime regions.

Operational Environments: Where Ice Class Matters

Ice class vessels are designed to navigate safely in harsh, icy waters such as the Arctic, Antarctic, and northern maritime routes where sea ice, icebergs, and freezing temperatures prevail. Non-ice class ships operate primarily in temperate or tropical regions without significant ice risks, making them unsuitable for polar or subpolar environments due to structural vulnerabilities. Your choice between ice class and non-ice class directly impacts operational safety and compliance when planning voyages through ice-prone routes.

Structural Reinforcements in Ice Class Vessels

Ice class vessels feature robust structural reinforcements, including thicker hull plating and strengthened framing to withstand harsh ice pressures, compared to non-ice class ships. These reinforcements typically extend to the bow, stern, and waterline areas where ice impact is most intense, ensuring enhanced durability and operational safety in polar regions. Non-ice class vessels lack these specialized reinforcements, making them vulnerable to hull breaches and structural damage when navigating icy waters.

Performance and Efficiency Comparison

Ice class vessels feature reinforced hulls and specialized structures to navigate through icy waters, enhancing safety and operational reliability in harsh conditions. Non-ice class ships lack these reinforcements, making them more vulnerable to ice damage, which can lead to increased maintenance costs and unexpected delays. Your choice between ice class and non-ice class impacts fuel efficiency and voyage speed, as ice class vessels often face higher resistance and fuel consumption but ensure consistent performance in icy environments.

Cost Implications: Building and Maintaining Ice Class Ships

Ice class ships require significantly higher construction costs due to reinforced hulls, specialized materials, and advanced engineering necessary for navigating icy waters. Maintenance expenses are also elevated, involving frequent inspections, repairs, and icebreaker assistance to prevent damage from ice impact. In contrast, non-ice class vessels have lower initial and ongoing costs but lack the durability and safety features needed for icy environments, limiting their operational scope.

Safety Features in Ice Class Versus Non-Ice Class

Ice class vessels are equipped with reinforced hulls, enhanced structural integrity, and specialized de-icing systems to withstand extreme cold and ice pressure, significantly improving safety in icy waters. Non-ice class ships lack these protective features, making them more vulnerable to hull breaches, mechanical failures, and navigation hazards in ice-covered regions. Your choice of an ice class ship ensures superior protection and operational reliability where ice conditions pose substantial risks.

Regulatory Compliance and Legal Considerations

Ice class vessels adhere to stringent regulatory frameworks such as the International Maritime Organization's Polar Code and specific classification society rules, ensuring enhanced structural integrity and safety in ice-covered waters. Non-ice class ships lack these reinforced standards, limiting their operational scope in icy conditions and increasing liability risks under maritime law. Compliance with ice class regulations mitigates legal consequences by aligning with international safety conventions and insurance requirements for Arctic and Antarctic voyages.

Choosing the Right Vessel: Factors to Consider

Ice class vessels are specially reinforced to navigate icy waters safely, making them essential for routes prone to ice conditions, while non-ice class vessels are built for open waters without ice hazards. Key factors in choosing the right vessel include the specific trade routes, expected ice severity, and regulatory requirements, ensuring operational safety and efficiency. Your decision should weigh these considerations to optimize performance and compliance in challenging maritime environments.

Ice class vs non-ice class Infographic

libmatt.com

libmatt.com