MDO (Medium-Density Overlay) offers a smooth, durable surface ideal for painting and exterior applications, while MGO (Magnesium Oxide) boards provide superior fire resistance, moisture resistance, and mold prevention, making them suitable for construction and industrial use. Your choice depends on whether you prioritize surface finish and aesthetics (MDO) or enhanced safety and durability in harsh environments (MGO).

Table of Comparison

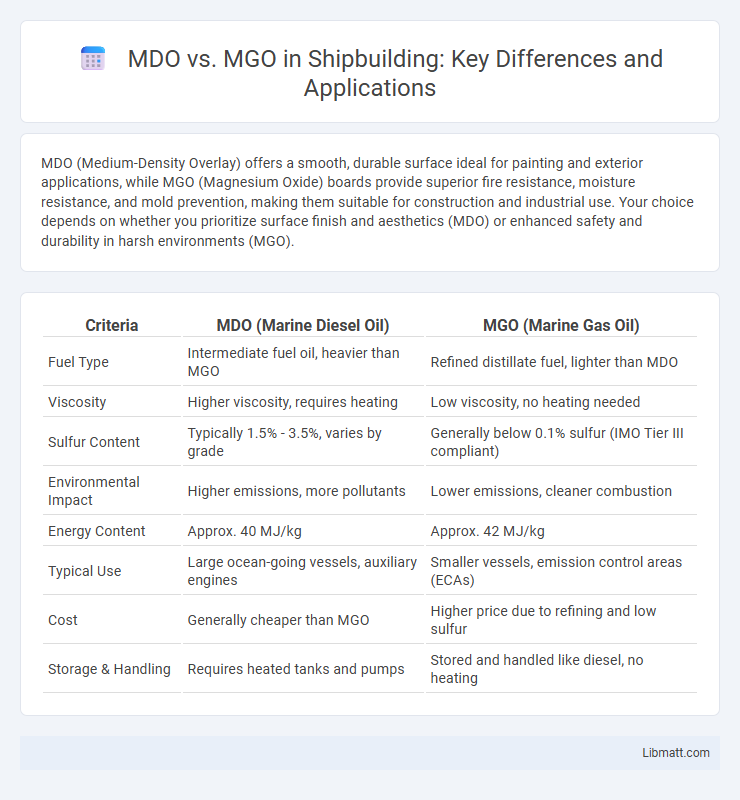

| Criteria | MDO (Marine Diesel Oil) | MGO (Marine Gas Oil) |

|---|---|---|

| Fuel Type | Intermediate fuel oil, heavier than MGO | Refined distillate fuel, lighter than MDO |

| Viscosity | Higher viscosity, requires heating | Low viscosity, no heating needed |

| Sulfur Content | Typically 1.5% - 3.5%, varies by grade | Generally below 0.1% sulfur (IMO Tier III compliant) |

| Environmental Impact | Higher emissions, more pollutants | Lower emissions, cleaner combustion |

| Energy Content | Approx. 40 MJ/kg | Approx. 42 MJ/kg |

| Typical Use | Large ocean-going vessels, auxiliary engines | Smaller vessels, emission control areas (ECAs) |

| Cost | Generally cheaper than MGO | Higher price due to refining and low sulfur |

| Storage & Handling | Requires heated tanks and pumps | Stored and handled like diesel, no heating |

Understanding MDO and MGO: Definitions and Composition

Marine Diesel Oil (MDO) is a blend of heavy fuel oil and marine gas oil designed for medium-speed engines, featuring higher viscosity and sulfur content compared to Marine Gas Oil (MGO). MGO is a distillate fuel derived from crude oil refining with lower viscosity and sulfur levels, suitable for high-speed engines and stricter emission regulations. The composition differences impact their combustion properties, environmental compliance, and engine compatibility in maritime applications.

Key Differences Between MDO and MGO

MDO (Marine Diesel Oil) and MGO (Marine Gas Oil) differ primarily in viscosity, sulfur content, and application within marine engines. MDO is heavier, blending residual fuel with lighter distillates, resulting in higher viscosity and sulfur levels, whereas MGO is a lighter distillate fuel with lower sulfur content, making it compliant with stricter emission regulations. Understanding these key differences helps you choose the appropriate fuel type to optimize engine performance and meet environmental standards.

Applications: When to Use MDO vs MGO

MDO (Marine Diesel Oil) is ideal for high-speed marine engines and smaller vessels due to its lower viscosity and easier combustion, making it suitable for applications requiring quick ignition and efficient fuel consumption. MGO (Marine Gas Oil) is preferred for auxiliary engines, emergency generators, and environmental compliance areas because of its cleaner burning properties and lower sulfur content. Your choice depends on engine type, operational requirements, and emission regulations, with MGO favored where stricter emissions standards apply and MDO used for cost-effective main engine fuel in certain conditions.

Technical Properties Comparison: MDO vs MGO

Marine Diesel Oil (MDO) and Marine Gas Oil (MGO) differ primarily in viscosity and sulfur content, with MDO having higher viscosity and typically higher sulfur levels than MGO, which is lighter and cleaner. MDO is a blend of heavy fuel oil and marine gas oil, offering better lubricity and energy density suitable for older engines, while MGO meets stricter environmental regulations due to its lower sulfur content and reduced emissions. Your choice between MDO and MGO should consider engine compatibility, fuel efficiency, and compliance with emission control area (ECA) standards.

Durability and Performance Factors

Marine Diesel Oil (MDO) offers higher lubricity and better contamination resistance compared to Marine Gas Oil (MGO), enhancing engine durability under varied operating conditions. MGO provides cleaner combustion with lower sulfur content, which improves performance by reducing engine deposits and maintenance intervals. The choice between MDO and MGO significantly affects engine wear, fuel stability, and emissions compliance, impacting overall vessel efficiency and longevity.

Cost Analysis: MDO vs MGO

Marine Diesel Oil (MDO) typically incurs higher costs compared to Marine Gas Oil (MGO) due to its blend of heavy fuel oil and distillate components, resulting in lower refining expenses for MGO. The pricing difference is influenced by sulfur content regulations, with MGO often priced higher in Sulfur Emission Control Areas (SECAs) because of its cleaner-burning properties and compliance with IMO 2020 sulfur limits. Operators must weigh the trade-off between MDO's lower upfront cost and MGO's potential savings on maintenance and regulatory penalties.

Environmental Impact and Sustainability

Marine Diesel Oil (MDO) produces higher sulfur emissions and particulate matter compared to Marine Gas Oil (MGO), leading to greater environmental pollution and ocean acidification. MGO, with lower sulfur content and better combustion efficiency, supports compliance with International Maritime Organization (IMO) sulfur cap regulations and reduces greenhouse gas emissions. Transitioning from MDO to MGO significantly enhances sustainability by minimizing air pollutants and promoting cleaner marine fuel alternatives aligned with global environmental standards.

Workability and Ease of Installation

MDO (Medium Density Overlay) plywood features a smooth, resin-impregnated fiber surface that enhances adhesion and makes cutting, drilling, and fastening easier during installation. MGO (Magnesium Oxide) boards, while durable and moisture-resistant, tend to be heavier and more brittle, requiring specialized tools and techniques, which can complicate workability and slow down the installation process. Choosing MDO can improve your project's efficiency with its user-friendly handling and straightforward installation.

Common Industries and Projects for MDO and MGO

Marine Diesel Oil (MDO) is commonly used in industries requiring medium-speed diesel engines, such as shipping companies operating container ships, fishing vessels, and ferry services, where reliable combustion and moderate sulfur content are essential. Marine Gas Oil (MGO) is preferred in sectors prioritizing low sulfur emissions, including cruise lines, offshore oil exploration vessels, and coastal shipping, aligning with stringent environmental regulations like IMO Tier III standards. Both fuels support various maritime projects, with MDO favored in heavy-duty offshore construction and dredging, while MGO frequently powers environmentally sensitive harbor operations and high-speed ferries.

How to Choose Between MDO and MGO

Choosing between MDO (Marine Diesel Oil) and MGO (Marine Gas Oil) depends on your vessel's engine specifications, operational requirements, and environmental regulations compliance. MDO, a heavier fuel, is typically used in older engines requiring less refined fuel, while MGO is cleaner, has lower sulfur content, and suits newer engines demanding higher combustion efficiency. Assess your engine type, emission control areas (ECAs) requirements, and fuel cost considerations to determine the best fuel option for your marine operations.

MDO vs MGO Infographic

libmatt.com

libmatt.com