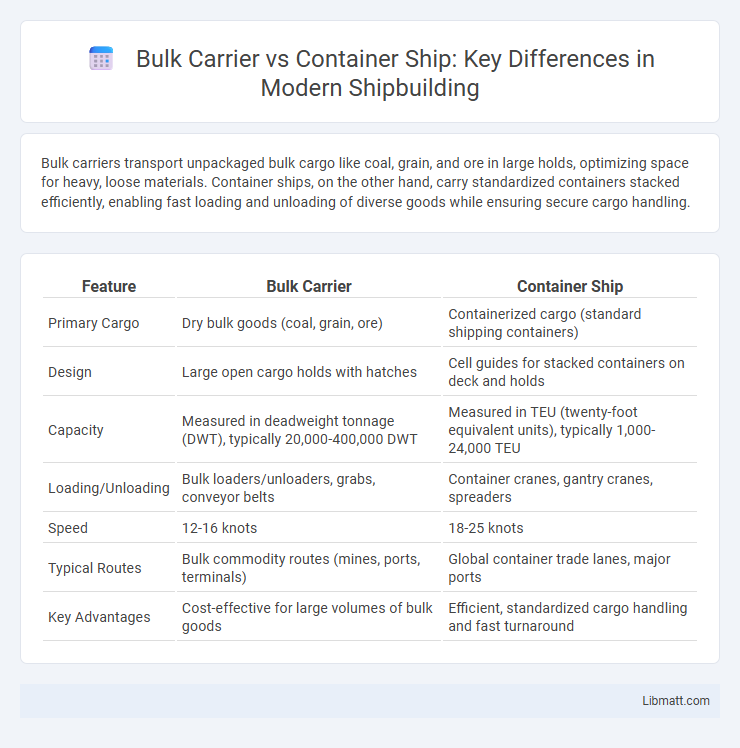

Bulk carriers transport unpackaged bulk cargo like coal, grain, and ore in large holds, optimizing space for heavy, loose materials. Container ships, on the other hand, carry standardized containers stacked efficiently, enabling fast loading and unloading of diverse goods while ensuring secure cargo handling.

Table of Comparison

| Feature | Bulk Carrier | Container Ship |

|---|---|---|

| Primary Cargo | Dry bulk goods (coal, grain, ore) | Containerized cargo (standard shipping containers) |

| Design | Large open cargo holds with hatches | Cell guides for stacked containers on deck and holds |

| Capacity | Measured in deadweight tonnage (DWT), typically 20,000-400,000 DWT | Measured in TEU (twenty-foot equivalent units), typically 1,000-24,000 TEU |

| Loading/Unloading | Bulk loaders/unloaders, grabs, conveyor belts | Container cranes, gantry cranes, spreaders |

| Speed | 12-16 knots | 18-25 knots |

| Typical Routes | Bulk commodity routes (mines, ports, terminals) | Global container trade lanes, major ports |

| Key Advantages | Cost-effective for large volumes of bulk goods | Efficient, standardized cargo handling and fast turnaround |

Introduction to Bulk Carriers and Container Ships

Bulk carriers are specialized vessels designed to transport unpackaged bulk cargo such as coal, grain, and ore, featuring large cargo holds optimized for heavy and dense materials. Container ships, on the other hand, are engineered to carry standardized cargo containers, providing efficient loading, unloading, and transport of diverse goods across global trade routes. Your choice between bulk carriers and container ships depends on the nature of the cargo and supply chain requirements.

Key Differences in Ship Design

Bulk carriers feature large, open cargo holds designed for transporting unpackaged bulk commodities such as coal, grain, and ore, allowing for easy loading and unloading of large volumes. Container ships utilize a cellular structure with fixed cell guides to securely stack and transport standardized intermodal containers, optimizing container handling efficiency and deck space. The hull design of bulk carriers emphasizes maximizing cargo volume and stability for heavy loads, whereas container ships focus on maintaining structural integrity and speed while carrying stacked containers.

Cargo Types and Handling Methods

Bulk carriers specialize in transporting unpackaged bulk cargo such as coal, grain, and ore, using large open holds and cranes or conveyor belts for loading and unloading. Container ships are designed to carry standardized cargo containers, streamlining the handling process with gantry cranes and facilitating easy transfer across different modes of transport. Your choice between the two depends on the type of cargo and the efficiency of loading and unloading methods suited to your shipping needs.

Loading and Unloading Procedures

Bulk carriers utilize cranes or conveyor systems to load and unload loose cargo such as coal, grain, and ore, with loading often performed through large hatches directly into the hold. Container ships rely on specialized gantry cranes to handle standardized containers, facilitating efficient stacking and precise placement on board for rapid turnaround. The loading and unloading of container ships are highly mechanized and structured, reducing port time compared to the more manual and variable bulk carrier operations.

Capacity and Volume Comparison

Bulk carriers transport unpackaged bulk cargo like coal and grain, featuring large cargo holds that maximize volume capacity, typically ranging from 10,000 to 400,000 deadweight tons (DWT). Container ships are designed to carry standardized containers, measured in twenty-foot equivalent units (TEUs), with capacities commonly between 1,000 to over 24,000 TEUs, optimizing space for stacked containers rather than cargo volume. Bulk carriers excel in volume capacity for dense, loose cargo, while container ships provide efficient, high-capacity transport for diverse, packaged goods.

Routes and Operational Flexibility

Bulk carriers primarily navigate established routes between major mining regions and industrial hubs, optimizing for large volumes of unpackaged bulk cargo like coal, ore, and grain. Container ships operate on a broader network of global trade lanes, offering greater operational flexibility by accommodating diverse cargo types and frequent port calls, which supports just-in-time delivery systems. Your logistical choices should consider the rigidity of bulk carrier routes versus the adaptable, multi-stop scheduling of container ships to maximize efficiency.

Safety and Risk Considerations

Bulk carriers face higher risks of structural failures and cargo shifting due to heavy, dense cargo like coal or ore, necessitating rigorous hull inspections and ballast management. Container ships encounter challenges related to container stacking stability, fire hazards from hazardous materials, and securing practices to prevent container loss overboard. Both vessel types require strict adherence to international safety regulations such as SOLAS and ISM codes to mitigate risks effectively.

Environmental Impact and Efficiency

Bulk carriers generally produce lower carbon emissions per ton of cargo compared to container ships due to simpler loading processes and fewer container handling operations. Container ships, while faster and more versatile, consume more fuel per voyage because of their complex cargo management and higher speeds, leading to increased greenhouse gas emissions. Advances in hull design and slow steaming practices are improving the energy efficiency and environmental performance of both vessel types in the shipping industry.

Cost Factors and Economic Implications

Bulk carriers generally have lower construction and operational costs compared to container ships due to their simpler design and ability to transport large volumes of homogeneous cargo like coal, grain, or ore. Container ships require more sophisticated technology and infrastructure for loading and unloading standardized containers, increasing port fees and handling expenses. Managing your logistics effectively demands understanding these economic implications to optimize shipment efficiency and reduce overall transportation costs.

Choosing the Right Vessel for Shipping Needs

Selecting the right vessel depends on cargo type and shipping efficiency; bulk carriers are ideal for transporting unpackaged bulk goods like coal, grain, and ore with large cargo holds designed for high weight capacity. Container ships excel in carrying standardized containers, ensuring faster loading/unloading, better cargo protection, and simplified logistics for diverse goods and global supply chains. Evaluating shipment volume, cargo nature, and port infrastructure optimizes vessel choice for cost-effective and timely delivery.

Bulk carrier vs container ship Infographic

libmatt.com

libmatt.com