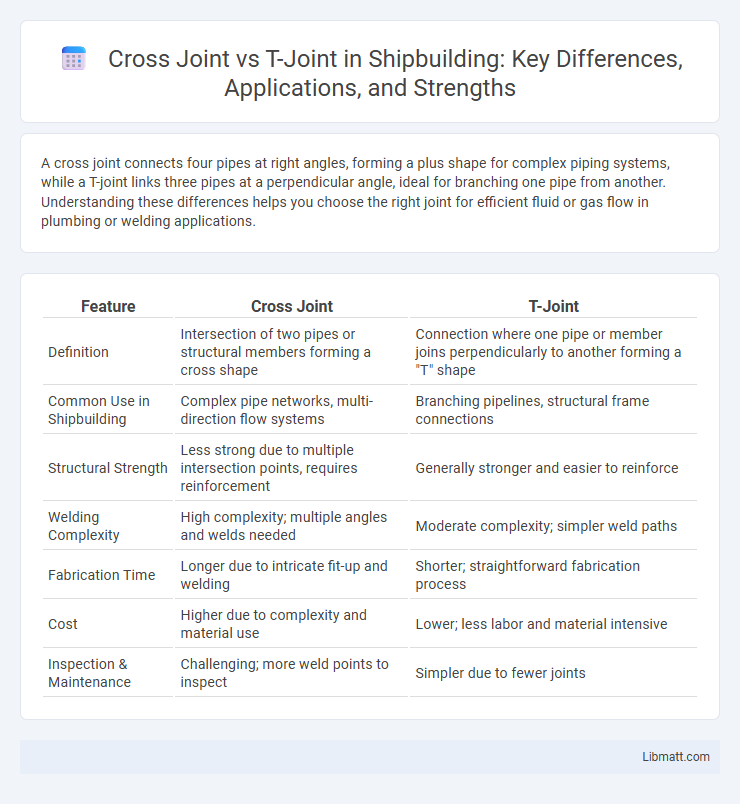

A cross joint connects four pipes at right angles, forming a plus shape for complex piping systems, while a T-joint links three pipes at a perpendicular angle, ideal for branching one pipe from another. Understanding these differences helps you choose the right joint for efficient fluid or gas flow in plumbing or welding applications.

Table of Comparison

| Feature | Cross Joint | T-Joint |

|---|---|---|

| Definition | Intersection of two pipes or structural members forming a cross shape | Connection where one pipe or member joins perpendicularly to another forming a "T" shape |

| Common Use in Shipbuilding | Complex pipe networks, multi-direction flow systems | Branching pipelines, structural frame connections |

| Structural Strength | Less strong due to multiple intersection points, requires reinforcement | Generally stronger and easier to reinforce |

| Welding Complexity | High complexity; multiple angles and welds needed | Moderate complexity; simpler weld paths |

| Fabrication Time | Longer due to intricate fit-up and welding | Shorter; straightforward fabrication process |

| Cost | Higher due to complexity and material use | Lower; less labor and material intensive |

| Inspection & Maintenance | Challenging; more weld points to inspect | Simpler due to fewer joints |

Introduction to Cross Joint and T-Joint

Cross joints connect four pipes at right angles, forming a plus-shaped intersection frequently used in plumbing and structural frameworks to distribute fluid or load evenly. T-joints link three pipes in a T-shape, enabling the redirection of flow or mechanical force at a 90-degree angle, essential for branching systems. Understanding these joints allows you to select the correct configuration for efficient piping layouts or structural assemblies.

Definition and Basic Concepts

A cross joint involves the intersection of two pipes at right angles, creating a four-way connection that allows flow from multiple directions. A T-joint, conversely, connects three pipes, forming a T-shaped intersection that directs flow primarily from one pipe into two others or vice versa. Understanding these basic configurations is essential for designing efficient piping systems in plumbing, HVAC, and industrial applications.

Structural Differences Between Cross Joint and T-Joint

Cross joints feature two pipes intersecting perpendicularly, creating a four-way connection that distributes stress evenly across all directions, enhancing structural integrity in complex piping systems. T-joints connect pipes at a right angle, forming a three-way connection that primarily channels flow in one main direction while providing a branch, which can introduce stress concentration at the junction. The structural differences significantly impact load distribution, with cross joints offering superior balance under multi-directional forces compared to T-joints, which are optimal for simpler, directional flow applications.

Applications and Common Uses

Cross joints are primarily used in construction and plumbing where four pipes or beams intersect, allowing for the distribution of materials or forces in multiple directions, making them ideal for complex structural frameworks. T-joints are commonly employed in piping systems and metal fabrication to connect three components at a right angle, facilitating branch flow or support structures in residential plumbing and HVAC systems. Both joints optimize space and material efficiency, but cross joints offer enhanced load distribution in multi-directional frameworks, while T-joints excel in simpler, directional connections.

Welding Techniques for Cross Joints

Cross joints require precise welding techniques such as groove welds or fillet welds to ensure strength and stability at the intersection of the two perpendicular metal pieces. Proper electrode selection and controlled heat input minimize distortion and improve penetration in cross joint welding, especially when using Shielded Metal Arc Welding (SMAW) or Gas Metal Arc Welding (GMAW). Effective joint preparation, including cleaning and beveling edges, is critical for achieving high-quality welds that resist stress and fatigue in cross joint applications.

Welding Techniques for T-Joints

Effective welding techniques for T-joints involve using fillet welds that provide strong, durable connections between perpendicular metal pieces. Common methods include Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Flux-Cored Arc Welding (FCAW), chosen based on material thickness and position. Proper joint preparation, correct electrode angle, and optimal heat control are crucial to prevent defects like cracking or incomplete fusion in T-joint welds.

Strength and Load Distribution Comparison

Cross joints provide superior strength and more uniform load distribution by intersecting multiple members at a single node, effectively transferring forces in multiple directions. T-joints, while simpler, concentrate stress at the intersection, resulting in lower overall strength and less efficient load distribution. Engineering analyses show cross joints enhance structural integrity, especially in frameworks subjected to multidirectional loads.

Advantages and Disadvantages

Cross joints offer enhanced structural stability by distributing loads in four directions, making them ideal for complex frameworks, but they can be more challenging to manufacture and require precise alignment. T-joints provide simpler construction and ease of access for welding or fastening, beneficial for straightforward assemblies, though they may experience higher stress concentration along the joint axis. Choosing between cross joints and T-joints depends on load distribution needs, fabrication complexity, and application-specific mechanical requirements.

Industry Standards and Best Practices

Cross joints and T-joints are both essential in piping and structural fabrication, with industry standards such as ASME B31.3 and AWS D1.1 defining their design and welding criteria to ensure safety and durability. Best practices emphasize proper fit-up, weld sequencing, and inspection protocols tailored to load distribution characteristics unique to each joint type. Understanding these standards helps you achieve compliance and optimize joint performance in critical applications.

Choosing the Right Joint for Your Project

Selecting the appropriate joint type depends on the structural requirements and load distribution of your project. Cross joints offer enhanced stability where four elements intersect, making them ideal for complex frameworks that need multidirectional support. T-joints suit simpler connections with two elements joining perpendicularly, providing strength and ease of assembly for straightforward load paths.

Cross joint vs T-joint Infographic

libmatt.com

libmatt.com