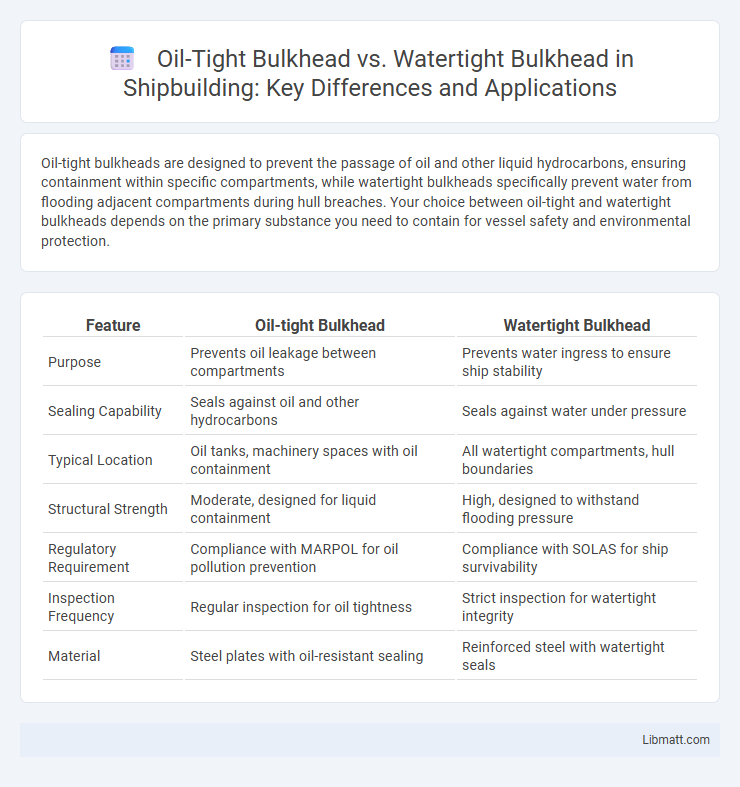

Oil-tight bulkheads are designed to prevent the passage of oil and other liquid hydrocarbons, ensuring containment within specific compartments, while watertight bulkheads specifically prevent water from flooding adjacent compartments during hull breaches. Your choice between oil-tight and watertight bulkheads depends on the primary substance you need to contain for vessel safety and environmental protection.

Table of Comparison

| Feature | Oil-tight Bulkhead | Watertight Bulkhead |

|---|---|---|

| Purpose | Prevents oil leakage between compartments | Prevents water ingress to ensure ship stability |

| Sealing Capability | Seals against oil and other hydrocarbons | Seals against water under pressure |

| Typical Location | Oil tanks, machinery spaces with oil containment | All watertight compartments, hull boundaries |

| Structural Strength | Moderate, designed for liquid containment | High, designed to withstand flooding pressure |

| Regulatory Requirement | Compliance with MARPOL for oil pollution prevention | Compliance with SOLAS for ship survivability |

| Inspection Frequency | Regular inspection for oil tightness | Strict inspection for watertight integrity |

| Material | Steel plates with oil-resistant sealing | Reinforced steel with watertight seals |

Introduction to Bulkheads in Marine Engineering

Oil-tight bulkheads are specialized barriers designed to prevent the passage of oil and other hydrocarbon liquids, ensuring containment of oil spills within specific compartments on a ship. Watertight bulkheads, by contrast, are structural partitions that prevent water ingress and maintain the vessel's buoyancy and stability in case of hull breaches or flooding. Both types of bulkheads are critical in marine engineering for safety, environmental protection, and compliance with maritime regulations such as SOLAS (Safety of Life at Sea).

Defining Oil-Tight Bulkheads

Oil-tight bulkheads are structural partitions designed to prevent the passage of oil, ensuring containment within specific compartments to avoid environmental contamination and maintain vessel stability. Unlike watertight bulkheads, which primarily resist water ingress for buoyancy and flood control, oil-tight bulkheads provide specialized sealing to handle hydrocarbon liquids under varying pressure conditions. These bulkheads typically feature enhanced sealing systems, such as gaskets and tight-fitting doors, to maintain the integrity of oil tanks and cargo holds on marine vessels.

Understanding Watertight Bulkheads

Watertight bulkheads are critical structural elements designed to prevent the passage of water between compartments in a ship, enhancing its safety during flooding. Unlike oil-tight bulkheads, which primarily contain liquid hydrocarbons and prevent oil leakage, watertight bulkheads ensure the vessel remains buoyant and stable by isolating flooded sections. Understanding your ship's watertight bulkheads is essential for effective damage control and maintaining maritime safety standards.

Key Differences Between Oil-Tight and Watertight Bulkheads

Oil-tight bulkheads are designed specifically to prevent the passage of oil and other hydrocarbons, featuring specialized seals and coatings to contain oil spills within compartments. Watertight bulkheads primarily focus on preventing water ingress and flooding in case of hull breaches, constructed with robust materials to maintain the ship's buoyancy and stability. The key differences lie in their sealing properties, intended fluids to contain, and structural design tailored to either oil retention or water tightness, crucial for maritime safety and environmental protection.

Primary Functions and Applications

Oil-tight bulkheads are designed primarily to prevent the passage of oil and fuel between compartments, ensuring containment in case of leaks or spills, and are commonly used in engine rooms and fuel storage tanks on ships. Watertight bulkheads serve to stop the ingress of water during flooding, maintaining a vessel's buoyancy and stability, and are crucial in ship hulls and compartments exposed to seawater. Both bulkheads play essential roles in maritime safety by compartmentalizing hazards but target different types of fluids based on specific safety requirements.

Regulatory Standards and Classification Society Requirements

Oil-tight bulkheads and watertight bulkheads both adhere to stringent regulatory standards established by the International Maritime Organization (IMO) under SOLAS (Safety of Life at Sea) conventions. Classification societies such as Lloyd's Register, DNV GL, and ABS enforce guidelines ensuring oil-tight bulkheads prevent oil leakage in oil tanks, while watertight bulkheads are designed to contain flooding within ship compartments. Compliance with these standards guarantees vessel integrity, environmental protection, and crew safety during maritime operations.

Materials and Construction Techniques

Oil-tight bulkheads are constructed using specialized steel plates and heavy-duty seals designed to resist oil permeation and withstand hydrocarbon exposure, often featuring welding methods that ensure impermeability and durability. Watertight bulkheads utilize robust steel or aluminum alloys with tight seam welding and rubber gaskets to prevent water ingress, prioritizing structural integrity and corrosion resistance in marine environments. Both types incorporate stiffeners and coatings tailored for their specific containment requirements, optimizing performance under pressure and environmental stress.

Performance in Emergency Situations

Oil-tight bulkheads prevent the spread of oil and fuel, maintaining compartment integrity during leaks or spills, which is critical for controlling fire and environmental hazards in emergency situations. Watertight bulkheads are designed to resist water ingress, preserving ship stability and buoyancy after hull breaches, essential for preventing sinking. Your choice depends on whether controlling liquid fuel containment or maintaining buoyancy is the priority in emergency performance.

Maintenance and Inspection Protocols

Oil-tight bulkheads require regular inspection for potential leaks or corrosion caused by exposure to oil and other hydrocarbons, with maintenance protocols emphasizing sealing integrity and surface treatments to prevent degradation. Watertight bulkheads demand frequent checks to ensure the solidity of seals and structural soundness to prevent water ingress, often involving pressure testing and detailed visual inspections. Your maintenance schedule should align with vessel type and operating conditions, prioritizing early detection procedures to maintain the effectiveness of both bulkhead types.

Choosing the Right Bulkhead for Vessel Safety

Oil-tight bulkheads prevent the spread of oil leaks within vessel compartments, ensuring environmental protection and operational integrity. Watertight bulkheads are designed to contain water ingress, maintaining buoyancy and stability during hull breaches. Selecting the appropriate bulkhead depends on the vessel's specific risk profile, cargo type, and regulatory requirements, with oil-tight bulkheads suited for oil tankers and watertight bulkheads critical for passenger ships and cargo vessels.

Oil-tight bulkhead vs watertight bulkhead Infographic

libmatt.com

libmatt.com