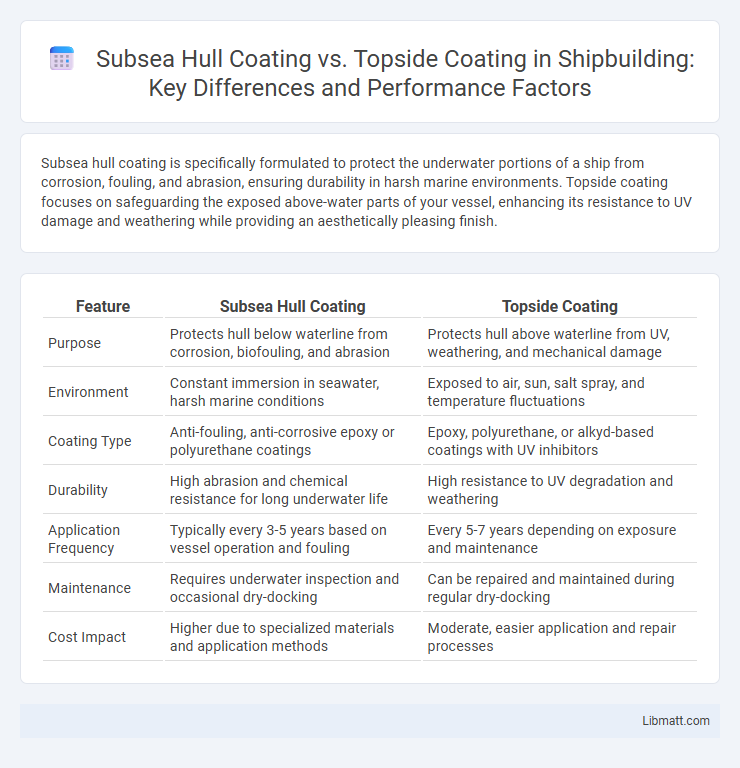

Subsea hull coating is specifically formulated to protect the underwater portions of a ship from corrosion, fouling, and abrasion, ensuring durability in harsh marine environments. Topside coating focuses on safeguarding the exposed above-water parts of your vessel, enhancing its resistance to UV damage and weathering while providing an aesthetically pleasing finish.

Table of Comparison

| Feature | Subsea Hull Coating | Topside Coating |

|---|---|---|

| Purpose | Protects hull below waterline from corrosion, biofouling, and abrasion | Protects hull above waterline from UV, weathering, and mechanical damage |

| Environment | Constant immersion in seawater, harsh marine conditions | Exposed to air, sun, salt spray, and temperature fluctuations |

| Coating Type | Anti-fouling, anti-corrosive epoxy or polyurethane coatings | Epoxy, polyurethane, or alkyd-based coatings with UV inhibitors |

| Durability | High abrasion and chemical resistance for long underwater life | High resistance to UV degradation and weathering |

| Application Frequency | Typically every 3-5 years based on vessel operation and fouling | Every 5-7 years depending on exposure and maintenance |

| Maintenance | Requires underwater inspection and occasional dry-docking | Can be repaired and maintained during regular dry-docking |

| Cost Impact | Higher due to specialized materials and application methods | Moderate, easier application and repair processes |

Introduction to Marine Coatings

Marine coatings are specialized protective layers applied to vessels' surfaces to prevent corrosion and biofouling in harsh marine environments. Subsea hull coatings are formulated to withstand prolonged underwater exposure, providing resistance to saltwater, abrasion, and marine growth, while topside coatings protect exposed areas above the waterline from UV damage, weathering, and mechanical wear. Your choice of coating impacts ship longevity, fuel efficiency, and maintenance costs, making the selection between subsea and topside coatings critical for optimal vessel performance.

What is Subsea Hull Coating?

Subsea hull coating is a specialized protective layer applied to the underwater portions of a vessel's hull to prevent corrosion, biofouling, and marine growth, enhancing the vessel's operational efficiency and longevity. These coatings are engineered to withstand harsh subsea conditions such as saltwater exposure, pressure variations, and abrasion from debris or marine organisms. Unlike topside coatings, which protect exposed areas above the waterline from UV radiation and weathering, subsea hull coatings use anti-fouling technology and durable materials to maintain a smooth surface below the water for reduced drag and fuel consumption.

What is Topside Coating?

Topside coating refers to the protective paint system applied to the above-water sections of offshore structures, such as oil rigs and ships, designed to withstand harsh environmental conditions like UV exposure, salt spray, and temperature fluctuations. These coatings prioritize resistance to corrosion, weathering, and abrasion, ensuring structural integrity and aesthetic maintenance. Understanding topside coating helps you select the right materials to protect assets exposed to atmospheric elements effectively.

Key Differences: Subsea vs Topside Coatings

Subsea hull coatings are specifically formulated to withstand prolonged exposure to harsh underwater environments, providing superior resistance to biofouling, corrosion, and abrasion, whereas topside coatings prioritize UV resistance, weather durability, and aesthetics for above-water surfaces. Subsea coatings often contain specialized antifouling agents and have enhanced adhesion properties to prevent marine growth and structural degradation below the waterline, while topside coatings focus on protecting against UV radiation, salt spray, and temperature fluctuations. Your choice between subsea and topside coatings should consider environmental conditions, substrate type, and maintenance needs to optimize vessel performance and longevity.

Environmental Challenges for Subsea and Topside Surfaces

Subsea hull coatings must withstand extreme pressures, low temperatures, and biofouling caused by marine organisms, which accelerate corrosion and reduce operational efficiency. Topside coatings face challenges from UV radiation, salt spray, temperature fluctuations, and chemical exposure, requiring high resistance to oxidation and abrasion. Both environments demand specialized anticorrosive and antifouling materials to ensure structural integrity and prolong service life in harsh offshore conditions.

Material Composition and Coating Formulations

Subsea hull coatings primarily utilize epoxy and polyurethane formulations designed for underwater corrosion resistance and biofouling prevention, featuring high adhesion and chemical stability in saline environments. Topside coatings are formulated with advanced alkyd and acrylic resins optimized for UV resistance, weather durability, and impact protection against harsh atmospheric conditions. The material composition differences reflect the distinct environmental stresses each coating must withstand, with subsea coatings emphasizing water impermeability and topside coatings focusing on abrasion resistance and color retention.

Application Methods: Subsea vs Topside

Subsea hull coating application involves specialized underwater techniques such as diver-applied coatings or remotely operated vehicles (ROVs) using abrasive blasting and epoxy-based paints designed to withstand high pressure and corrosive saltwater environments. Topside coatings are typically applied using spray, brush, or roller methods in controlled environments, focusing on UV resistance and weather durability for exposed areas above the waterline. Your choice of coating and application method must consider the distinct environmental conditions and maintenance accessibility to ensure maximum protection and longevity of the vessel's hull.

Performance and Durability Under Marine Conditions

Subsea hull coatings exhibit superior performance and enhanced durability under harsh marine conditions due to their resistance to biofouling, corrosion, and high hydrostatic pressure, which are prevalent in submerged environments. Topside coatings prioritize UV resistance, impact tolerance, and weatherproofing to withstand exposure to sunlight, salt spray, and atmospheric corrosion on above-water surfaces. Advanced formulations in subsea coatings incorporate antifouling technologies that reduce marine growth and improve fuel efficiency, whereas topside coatings focus on maintaining structural integrity and aesthetic appearance under fluctuating temperature and humidity.

Maintenance and Lifespan Considerations

Subsea hull coatings prioritize corrosion resistance and biofouling prevention to extend the lifespan of underwater vessel surfaces, reducing maintenance frequency due to harsh marine environments. Topside coatings emphasize UV resistance and mechanical durability against weather and operational wear, enabling easier maintenance and touch-ups during routine inspections. Selecting appropriate coatings based on environment-specific stressors significantly improves vessel asset longevity and cost-efficiency in maintenance cycles.

Choosing the Right Coating: Factors and Recommendations

Selecting the appropriate coating for subsea hulls versus topside surfaces hinges on environmental exposure, material compatibility, and operational conditions. Subsea hull coatings require superior antifouling properties, corrosion resistance, and durability against constant seawater immersion, while topside coatings must withstand UV radiation, temperature fluctuations, and mechanical wear. Recommendations emphasize using specialized epoxy or polyurethane systems for submerged sections and UV-resistant polyurethane or fluoropolymer coatings for topside areas to optimize asset longevity and performance.

Subsea hull coating vs topside coating Infographic

libmatt.com

libmatt.com