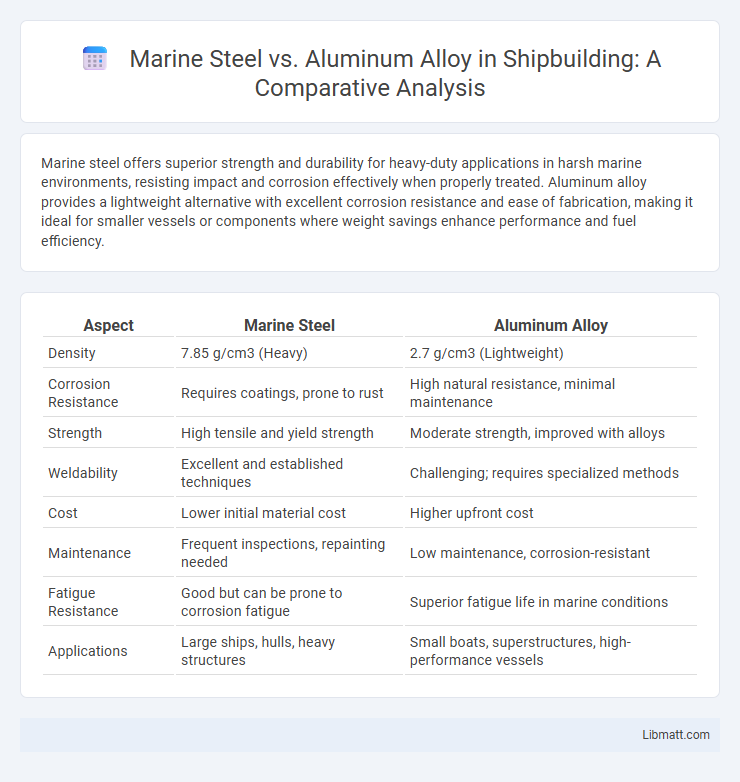

Marine steel offers superior strength and durability for heavy-duty applications in harsh marine environments, resisting impact and corrosion effectively when properly treated. Aluminum alloy provides a lightweight alternative with excellent corrosion resistance and ease of fabrication, making it ideal for smaller vessels or components where weight savings enhance performance and fuel efficiency.

Table of Comparison

| Aspect | Marine Steel | Aluminum Alloy |

|---|---|---|

| Density | 7.85 g/cm3 (Heavy) | 2.7 g/cm3 (Lightweight) |

| Corrosion Resistance | Requires coatings, prone to rust | High natural resistance, minimal maintenance |

| Strength | High tensile and yield strength | Moderate strength, improved with alloys |

| Weldability | Excellent and established techniques | Challenging; requires specialized methods |

| Cost | Lower initial material cost | Higher upfront cost |

| Maintenance | Frequent inspections, repainting needed | Low maintenance, corrosion-resistant |

| Fatigue Resistance | Good but can be prone to corrosion fatigue | Superior fatigue life in marine conditions |

| Applications | Large ships, hulls, heavy structures | Small boats, superstructures, high-performance vessels |

Overview: Marine Steel vs Aluminum Alloy

Marine steel offers superior strength and corrosion resistance, making it ideal for heavy-duty shipbuilding and offshore structures. Aluminum alloy provides lightweight durability and excellent resistance to marine corrosion, favored in high-speed vessels and luxury yachts. Both materials balance structural integrity and longevity, with steel excelling in toughness and aluminum in weight efficiency.

Material Composition and Properties

Marine steel is primarily composed of iron with small amounts of carbon and alloying elements like manganese and nickel, providing high tensile strength and excellent corrosion resistance when properly treated. Aluminum alloy used in marine environments typically contains varying percentages of aluminum mixed with elements such as copper, magnesium, and zinc, offering superior corrosion resistance, lighter weight, and good strength-to-weight ratio. The choice between marine steel and aluminum alloy depends on the specific balance of durability, weight, and corrosion resistance required for shipbuilding and offshore applications.

Weight Comparison: Steel vs Aluminum

Marine steel typically weighs about 7,850 kg/m3, making it significantly heavier than aluminum alloy, which averages around 2,700 kg/m3. This weight difference allows aluminum boats to achieve better fuel efficiency and faster speeds due to reduced overall mass. Despite aluminum's lighter weight, steel offers superior strength and durability, often requiring thicker construction for comparable performance.

Corrosion Resistance in Marine Environments

Marine steel offers strong structural integrity but requires regular maintenance due to its susceptibility to rust and corrosion in saltwater environments. Aluminum alloy provides superior corrosion resistance because of its natural oxide layer that protects against saltwater degradation, making it ideal for harsh marine conditions. Your choice between the two materials should consider long-term durability and maintenance needs in marine applications.

Strength and Structural Performance

Marine steel offers superior strength and durability, making it ideal for heavy-duty structural applications where high load-bearing capacity is critical. Aluminum alloy provides excellent corrosion resistance and lighter weight, enhancing vessel speed and fuel efficiency while maintaining adequate strength for moderate structural demands. Your choice between these materials should consider the balance between required strength, structural performance, and vessel design priorities.

Maintenance and Longevity

Marine steel offers exceptional durability and requires regular maintenance to prevent rust and corrosion, often involving frequent inspections and protective coatings. Aluminum alloy, while lighter and corrosion-resistant, demands less upkeep but may be more prone to fatigue and impact damage over time. Choosing the right material for your vessel depends on balancing maintenance efforts with the expected lifespan and environmental exposure.

Cost Analysis: Initial and Lifetime Expenses

Marine steel typically has a lower initial cost than aluminum alloy, making it a budget-friendly option for hull construction. However, steel requires more maintenance due to corrosion risks, leading to higher lifetime expenses compared to aluminum alloy, which offers superior corrosion resistance and reduced upkeep costs. Over the vessel's lifespan, aluminum alloy can provide better cost efficiency despite its higher upfront price, especially in saltwater environments.

Fabrication and Repair Considerations

Marine steel offers superior strength and durability, making it easier to weld and repair with standard techniques, ideal for heavy-duty applications that require frequent maintenance. Aluminum alloy provides lightweight advantages and corrosion resistance but demands specialized welding equipment and skilled labor to avoid damage during fabrication and repairs. Your choice depends on balancing fabrication complexity with long-term maintenance requirements in marine environments.

Environmental Impact and Sustainability

Marine steel exhibits a higher carbon footprint due to intensive mining and energy-consuming production processes, while aluminum alloy benefits from improved recyclability and lower life-cycle emissions. The sustainable use of aluminum in marine applications is supported by its corrosion resistance, which prolongs vessel lifespan and reduces material replacement frequency. Steel's heavier weight increases fuel consumption, contributing to higher greenhouse gas emissions compared to lightweight aluminum alloys, which promote energy efficiency in marine transportation.

Application Suitability: Best Uses for Each Material

Marine steel is ideal for heavy-duty applications such as ship hulls, offshore platforms, and structural components due to its exceptional strength, durability, and resistance to impact. Aluminum alloy is best suited for smaller vessels, yacht superstructures, and components requiring lightweight properties combined with corrosion resistance, enhancing fuel efficiency and maneuverability. Choosing between marine steel and aluminum alloy depends on factors like load-bearing requirements, weight constraints, and environmental exposure.

Marine steel vs aluminum alloy Infographic

libmatt.com

libmatt.com