Air-curing enhances the hardness and strength of metals through slow oxidation at ambient temperatures, improving surface toughness without compromising the core material. Case hardening involves heating the metal and introducing carbon or nitrogen to create a hardened outer layer while preserving a ductile interior, ideal for components requiring wear resistance and impact absorption.

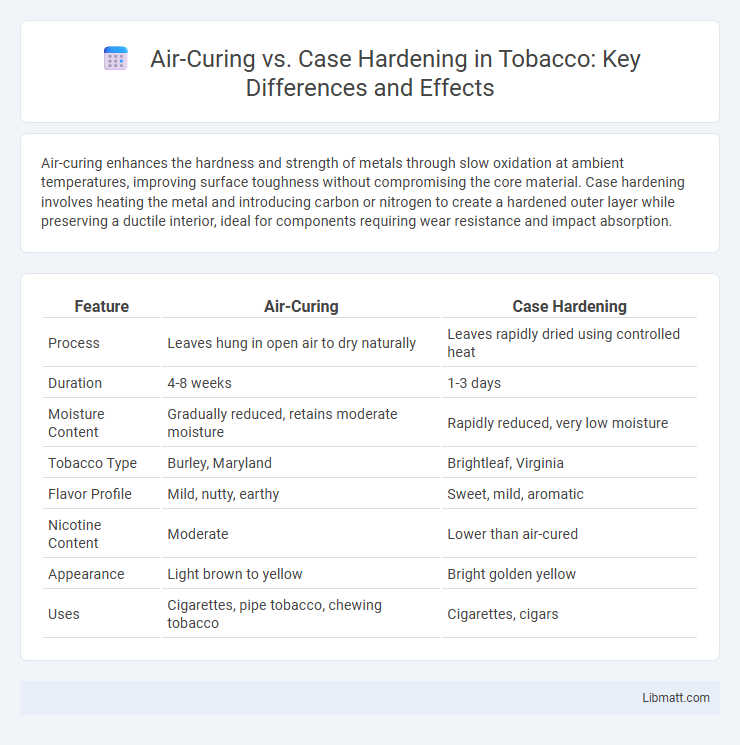

Table of Comparison

| Feature | Air-Curing | Case Hardening |

|---|---|---|

| Process | Leaves hung in open air to dry naturally | Leaves rapidly dried using controlled heat |

| Duration | 4-8 weeks | 1-3 days |

| Moisture Content | Gradually reduced, retains moderate moisture | Rapidly reduced, very low moisture |

| Tobacco Type | Burley, Maryland | Brightleaf, Virginia |

| Flavor Profile | Mild, nutty, earthy | Sweet, mild, aromatic |

| Nicotine Content | Moderate | Lower than air-cured |

| Appearance | Light brown to yellow | Bright golden yellow |

| Uses | Cigarettes, pipe tobacco, chewing tobacco | Cigarettes, cigars |

Introduction to Air-Curing and Case Hardening

Air-curing involves slowly hardening steel or iron components by exposing them to air, enhancing surface strength without altering the core properties. Case hardening, also known as surface hardening, introduces carbon or nitrogen to the metal's exterior, creating a tough, wear-resistant outer layer while maintaining a softer, ductile interior. You can choose air-curing for uniform hardness or case hardening for improved surface durability in applications like gears and bearings.

Defining Air-Curing: Process and Applications

Air-curing is a metal treatment process where steel is cooled slowly in ambient air after heating, allowing internal stresses to reduce and improving toughness without altering the core hardness significantly. This method is commonly applied in manufacturing components requiring balanced strength and ductility, such as in automotive parts and structural steelworks. Understanding your product's performance needs helps determine if air-curing is the suitable choice for enhancing durability and wear resistance.

Understanding Case Hardening: Techniques and Uses

Case hardening involves surface hardening techniques such as carburizing, nitriding, and cyaniding to enhance the wear resistance of steel components by infusing carbon or nitrogen into the outer layer while maintaining a softer core. Unlike air-curing, which relies on slow oxidation or drying processes to harden materials over time, case hardening rapidly strengthens metal surfaces for applications requiring increased durability and fatigue resistance, including gears, cams, and crankshafts. This method is critical in manufacturing industries where components demand high surface hardness without compromising overall toughness.

Key Differences Between Air-Curing and Case Hardening

Air-curing involves slowly drying materials, primarily tobacco or wood, exposing them to ambient air to reduce moisture content without altering surface hardness. Case hardening is a heat treatment process that increases surface hardness of steel parts by infusing elements like carbon or nitrogen, creating a hard outer layer while maintaining a ductile core. Key differences include the materials processed, the purpose--moisture reduction versus surface hardness enhancement--and the mechanisms, with air-curing relying on natural drying and case hardening using controlled chemical reactions and heat.

Material Compatibility: Optimal Choices for Each Method

Air-curing is best suited for ferrous alloys like steel and cast iron, where gradual cooling prevents cracking and preserves toughness. Case hardening is ideal for low-carbon steels, enhancing surface hardness while maintaining a ductile core. Your material choice directly impacts the effectiveness of each method, ensuring optimal performance and durability.

Effects on Mechanical Properties and Durability

Air-curing enhances the toughness and ductility of steel by allowing slower cooling, which results in a more uniform microstructure and improved resistance to cracking. Case hardening significantly increases surface hardness and wear resistance by creating a hardened outer layer while maintaining a tough, ductile core, thereby extending the component's durability under stress. Your choice depends on the required balance between surface hardness and overall mechanical robustness for specific applications.

Industry Applications: Where Each Method Excels

Air-curing excels in the manufacturing of high-strength steel components and automotive parts where uniform hardness and wear resistance are critical, especially in environments requiring minimal distortion. Case hardening is preferred in the production of gears, camshafts, and crankshafts, providing a tough core with a hard, wear-resistant surface ideal for components subjected to heavy surface stress and fatigue. Both methods optimize performance and durability across aerospace, automotive, and heavy machinery industries by enhancing mechanical properties suited to specific operational demands.

Environmental and Cost Considerations

Air-curing offers a more environmentally friendly process by eliminating the need for hazardous chemicals and reducing energy consumption compared to case hardening, which often involves toxic carburizing gases and higher operational costs. Your choice of air-curing can significantly lower both environmental impact and overall expenses, making it a cost-effective solution for sustainable metal treatment. Case hardening, while providing superior surface hardness, incurs higher costs due to specialized equipment and chemical management, which may not align with eco-conscious production goals.

Quality Control and Testing Requirements

Air-curing steels demand rigorous quality control involving dimensional stability checks and metallographic examinations to ensure uniform hardness and minimal distortion. Case hardening requires stringent testing protocols such as microhardness testing across the case depth and non-destructive evaluation to verify surface hardness and case integrity. Your quality control program must adapt to these differing requirements to achieve optimal material performance and longevity.

Choosing the Right Method: Factors to Consider

Choosing the right method between air-curing and case hardening depends on factors such as the desired surface hardness, corrosion resistance, and application environment. Air-curing is ideal for materials requiring uniform hardness and long-term durability, while case hardening enhances wear resistance by creating a hard outer layer on softer metals. Your selection should align with the mechanical properties needed and the specific performance requirements of the finished product.

air-curing vs case hardening Infographic

libmatt.com

libmatt.com