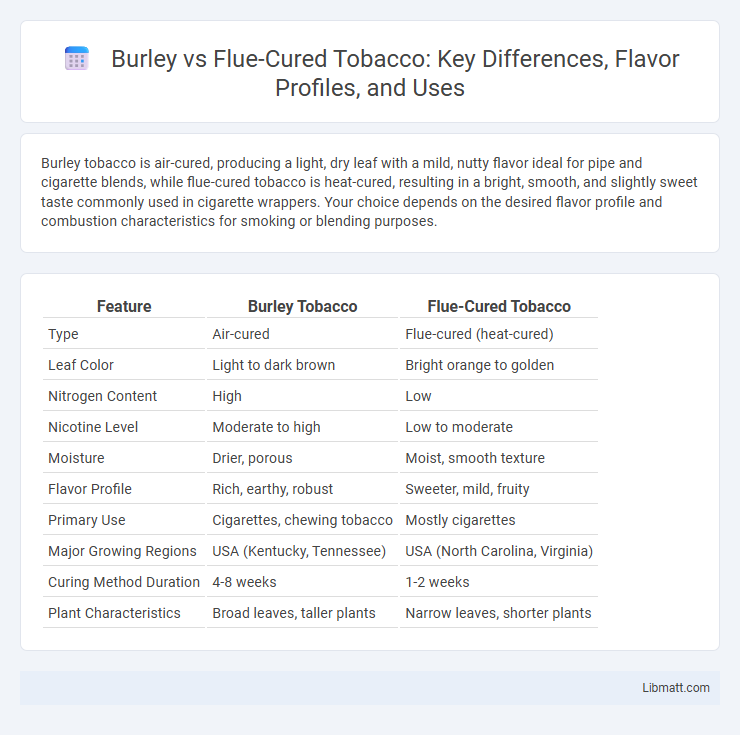

Burley tobacco is air-cured, producing a light, dry leaf with a mild, nutty flavor ideal for pipe and cigarette blends, while flue-cured tobacco is heat-cured, resulting in a bright, smooth, and slightly sweet taste commonly used in cigarette wrappers. Your choice depends on the desired flavor profile and combustion characteristics for smoking or blending purposes.

Table of Comparison

| Feature | Burley Tobacco | Flue-Cured Tobacco |

|---|---|---|

| Type | Air-cured | Flue-cured (heat-cured) |

| Leaf Color | Light to dark brown | Bright orange to golden |

| Nitrogen Content | High | Low |

| Nicotine Level | Moderate to high | Low to moderate |

| Moisture | Drier, porous | Moist, smooth texture |

| Flavor Profile | Rich, earthy, robust | Sweeter, mild, fruity |

| Primary Use | Cigarettes, chewing tobacco | Mostly cigarettes |

| Major Growing Regions | USA (Kentucky, Tennessee) | USA (North Carolina, Virginia) |

| Curing Method Duration | 4-8 weeks | 1-2 weeks |

| Plant Characteristics | Broad leaves, taller plants | Narrow leaves, shorter plants |

Introduction to Burley and Flue-Cured Tobacco

Burley tobacco, known for its light air-cured leaves, is primarily grown in Kentucky and Tennessee, producing a mild flavor suited for cigarettes and pipe tobacco. Flue-cured tobacco, predominantly cultivated in North Carolina, undergoes heat-curing with controlled temperatures to develop a bright, sweet flavor essential for many cigarette blends. Both types play crucial roles in the tobacco industry, offering distinct taste profiles and curing methods that influence their end use.

Historical Background of Burley and Flue-Cured Varieties

Burley tobacco, originating in the mid-19th century in the United States, was developed for its air-cured properties, producing a light, low-nicotine leaf ideal for blending and cigarettes. Flue-cured tobacco, with roots dating back to the colonial era, is characterized by its bright, high-sugar leaves cured through controlled heat, popular in American-type cigarettes. Understanding the historical background of these varieties helps you appreciate their distinct curing processes and flavor profiles essential to tobacco production and consumption.

Key Differences in Cultivation Practices

Burley tobacco requires a longer curing process, typically air curing, which involves hanging the leaves in well-ventilated barns to dry slowly, while flue-cured tobacco undergoes a faster, heated curing method using flues to control temperature. Burley plants are more tolerant of lower soil fertility and are often grown in shaded or less sunny areas, whereas flue-cured tobacco thrives in well-drained, sandy soils with ample sunlight. Your choice between burley and flue-cured cultivation will impact labor intensity, curing time, and field management techniques due to these fundamental agricultural differences.

Curing Methods: Air-Curing vs. Flue-Curing

Burley tobacco undergoes air-curing, a natural process where leaves are hung in well-ventilated barns to dry slowly, enhancing its light, mellow flavor with lower sugar content. In contrast, flue-cured tobacco is dried using indirect heat in enclosed barns, a method that intensifies its sweetness and produces a brighter, more aromatic leaf. Understanding these curing differences helps you choose the tobacco style that best suits your flavor preferences and smoking experience.

Distinctive Chemical and Physical Properties

Burley tobacco contains lower sugar content and higher nicotine levels compared to flue-cured tobacco, resulting in a drier, air-cured leaf with a light brown color and a more robust, earthy flavor profile. Flue-cured tobacco, primarily Virginia tobacco, has higher sugar content, which contributes to its sweeter taste and bright orange to reddish-brown color due to the flue-curing process that uses controlled heat without smoke. Your choice between burley and flue-cured tobacco influences the chemical composition and moisture content, directly affecting the burning characteristics and overall smoking experience.

Usage in Different Tobacco Products

Burley tobacco is primarily used in cigarette blends for its light, porous leaf that absorbs flavors well, making it ideal for flavored and additive-enhanced tobacco products. Flue-cured tobacco, known for its sweet, mild taste and high sugar content, is predominantly used in cigarettes like American blends for its smooth smoke and aromatic qualities. Both Burley and flue-cured tobaccos are essential in crafting diverse cigarette profiles, with Burley contributing body and strength, while flue-cured adds sweetness and aroma.

Flavor Profiles and Smoking Experience

Burley tobacco offers a mild, nutty flavor with a natural sweetness, providing a smooth and slow-burning smoking experience that enhances flavor complexity over time. Flue-cured tobacco delivers a bright, crisp taste with hints of citrus and a slightly sweet finish, resulting in a cleaner and more immediate smoking sensation. These distinct flavor profiles influence personal preference, with burley favored for its rich depth and flue-cured chosen for its vibrant and lighter character.

Economic Impact on Tobacco Markets

Burley tobacco typically commands lower market prices than flue-cured tobacco due to differences in curing processes and flavor profiles, influencing growers' profit margins and regional cultivation choices. Flue-cured tobacco, preferred for its mild flavor and higher nicotine content, drives stronger demand in premium markets, bolstering economic returns for producers in states like North Carolina. Market volatility in burley tobacco often affects wholesale prices and contract stability, impacting small-scale farmers more significantly compared to the relatively stable flue-cured segment.

Major Growing Regions Worldwide

Burley tobacco is predominantly cultivated in the United States, particularly in Kentucky, Tennessee, and North Carolina, as well as in parts of Malawi and Zimbabwe, where its air-cured process suits the humid climates. Flue-cured tobacco thrives mainly in the southeastern United States, especially North Carolina and South Carolina, with significant production also in countries like Brazil, Zimbabwe, and China, benefiting from warmer, dryer conditions needed for its bright, cured leaves. These distinct growing regions reflect the crop's adaptation to environmental factors critical for producing the specific characteristics of burley and flue-cured tobacco.

Health Considerations and Regulatory Issues

Burley and flue-cured tobaccos differ significantly in nitrogen and sugar content, impacting the levels of harmful compounds such as tar and nicotine in smoke. Health considerations include varying risks of addiction and respiratory issues due to these chemical differences, with flue-cured tobacco typically producing higher sugar-related toxins. Regulatory issues also diverge, as some regions impose stricter limits on nitrosamine levels more prominent in burley tobacco, affecting cultivation and product labeling standards that may influence your tobacco choices.

burley vs flue-cured Infographic

libmatt.com

libmatt.com