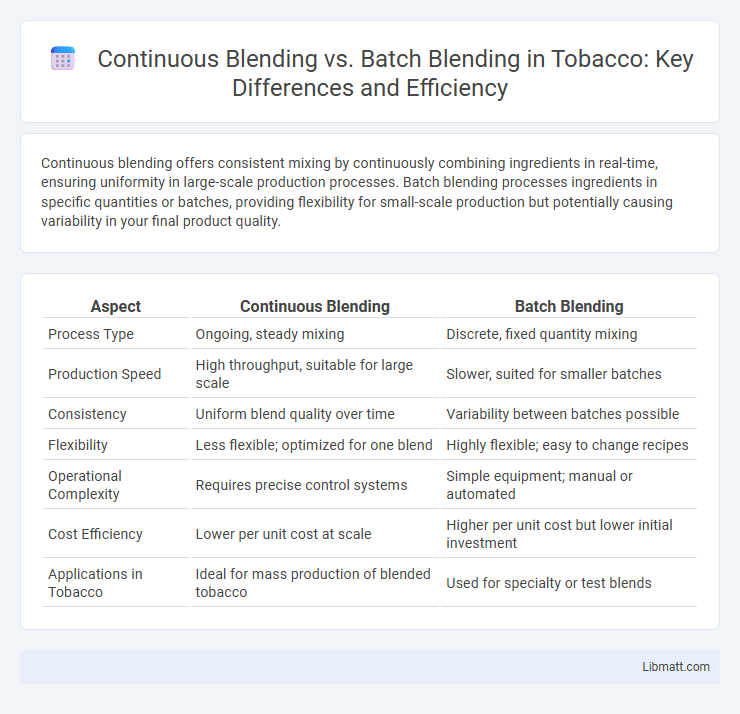

Continuous blending offers consistent mixing by continuously combining ingredients in real-time, ensuring uniformity in large-scale production processes. Batch blending processes ingredients in specific quantities or batches, providing flexibility for small-scale production but potentially causing variability in your final product quality.

Table of Comparison

| Aspect | Continuous Blending | Batch Blending |

|---|---|---|

| Process Type | Ongoing, steady mixing | Discrete, fixed quantity mixing |

| Production Speed | High throughput, suitable for large scale | Slower, suited for smaller batches |

| Consistency | Uniform blend quality over time | Variability between batches possible |

| Flexibility | Less flexible; optimized for one blend | Highly flexible; easy to change recipes |

| Operational Complexity | Requires precise control systems | Simple equipment; manual or automated |

| Cost Efficiency | Lower per unit cost at scale | Higher per unit cost but lower initial investment |

| Applications in Tobacco | Ideal for mass production of blended tobacco | Used for specialty or test blends |

Introduction to Blending Methods

Continuous blending involves the constant combination of raw materials through automated systems, ensuring uniform product quality and increased production efficiency in industries like food, pharmaceuticals, and chemicals. Batch blending processes materials in set quantities, offering flexibility for smaller production runs and easy adjustments to formulations. Choosing between continuous and batch blending depends on factors such as production volume, product consistency requirements, and operational costs.

What is Continuous Blending?

Continuous blending is a manufacturing process where raw materials are continuously fed into a blending system, producing a homogeneous mixture without interruption. This method ensures consistent product quality and uniformity by maintaining steady flow rates and precise proportions of ingredients throughout the operation. It is widely used in industries such as pharmaceuticals, food production, and chemicals to optimize efficiency and reduce production time compared to batch blending.

What is Batch Blending?

Batch blending is a manufacturing process where ingredients are mixed in fixed, separate quantities to create a specific formulation at one time. This method allows precise control over each batch's composition, ensuring consistency and quality for products such as pharmaceuticals, food, and chemicals. Your choice between batch and continuous blending depends on production volume, flexibility needs, and quality requirements.

Key Differences Between Continuous and Batch Blending

Continuous blending processes operate non-stop, allowing for a constant mix of materials, ideal for large-scale production with consistent composition. Batch blending involves mixing fixed quantities of materials in separate lots, offering flexibility and precise control over individual blend formulations. Key differences include processing time, scalability, product consistency, and operational flexibility tailored to varying production needs.

Advantages of Continuous Blending

Continuous blending offers enhanced efficiency by providing a steady, uninterrupted mixing process that minimizes downtime and reduces labor costs. This method ensures consistent product quality with precise control over ingredient ratios, improving overall reliability and reducing waste compared to batch blending. Your production line benefits from greater scalability and faster throughput, making continuous blending ideal for high-volume manufacturing.

Advantages of Batch Blending

Batch blending offers precise control over ingredient proportions, ensuring consistent product quality and formulation accuracy. It allows for easier adjustments and flexibility in producing varying product sizes and formulations, making it ideal for customized or small-scale production. Batch processes also facilitate thorough quality checks at each stage, reducing the risk of contamination and product variation.

Choosing the Right Blending Method

Choosing the right blending method depends on the production scale, consistency requirements, and ingredient characteristics. Continuous blending offers precise control and uniform mixing ideal for large-scale operations with consistent formulations, while batch blending provides flexibility for small-scale production and multiple recipe variations. Factors like processing speed, cost efficiency, and quality control must guide the decision between continuous and batch blending systems.

Industry Applications for Continuous Blending

Continuous blending excels in industries requiring high-throughput and consistent product quality, such as pharmaceuticals, food processing, and chemical manufacturing, by enabling precise real-time ingredient mixing. Its application in large-scale production lines enhances efficiency and reduces downtime compared to traditional batch blending methods. Industries benefit from continuous blending's ability to maintain homogeneous mixtures while supporting automation and scalable processes.

Industry Applications for Batch Blending

Batch blending is widely used in industries requiring precise formulation and product customization, such as pharmaceuticals, food processing, and specialty chemicals. This method allows for flexible recipe adjustments and quality control by handling discrete quantities of raw materials in each batch. Batch blending is ideal for sectors where traceability and consistency in small to medium production runs are critical.

Summary: Which Blending Method is Best?

Continuous blending offers superior consistency and efficiency by maintaining a steady mixing process, ideal for large-scale production with uniform ingredient flow. Batch blending provides flexibility for small to medium volumes and allows customization but may suffer from variability and longer processing times. For highly consistent quality and high throughput, continuous blending is generally the best choice; batch blending suits applications requiring frequent recipe changes or smaller production runs.

continuous blending vs batch blending Infographic

libmatt.com

libmatt.com