Drag resistance measures the frictional force opposing motion through a fluid, while the dilution index quantifies the spread or concentration of a solute within a medium. Understanding the relationship between drag resistance and dilution index helps optimize fluid dynamics in applications such as chemical mixing or environmental dispersion, improving Your system's efficiency and performance.

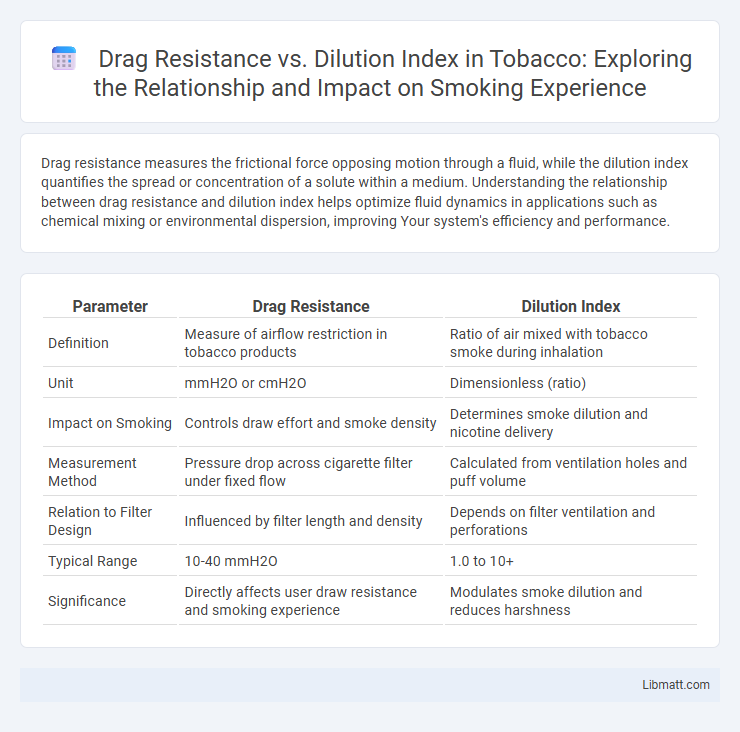

Table of Comparison

| Parameter | Drag Resistance | Dilution Index |

|---|---|---|

| Definition | Measure of airflow restriction in tobacco products | Ratio of air mixed with tobacco smoke during inhalation |

| Unit | mmH2O or cmH2O | Dimensionless (ratio) |

| Impact on Smoking | Controls draw effort and smoke density | Determines smoke dilution and nicotine delivery |

| Measurement Method | Pressure drop across cigarette filter under fixed flow | Calculated from ventilation holes and puff volume |

| Relation to Filter Design | Influenced by filter length and density | Depends on filter ventilation and perforations |

| Typical Range | 10-40 mmH2O | 1.0 to 10+ |

| Significance | Directly affects user draw resistance and smoking experience | Modulates smoke dilution and reduces harshness |

Introduction to Drag Resistance and Dilution Index

Drag resistance measures the force opposing motion in fluids, critical for optimizing aerodynamic and hydrodynamic performance. Dilution index quantifies the degree of mixing between a pollutant and ambient fluid, essential in environmental engineering and fluid dynamics. Understanding the interaction between drag resistance and dilution index enhances system efficiency and pollutant dispersion predictions.

Understanding Drag Resistance: Definition and Significance

Drag resistance measures the frictional force opposing the motion of a fluid through a medium, directly impacting the efficiency of fluid flow systems. Its significance lies in optimizing designs to reduce energy consumption and improve performance in applications such as aerodynamics, pipelines, and filtration processes. Understanding drag resistance is essential for accurately predicting flow behavior and enhancing system durability and operation.

Exploring the Dilution Index: Core Concepts

The Dilution Index quantifies the reduction in drag resistance caused by the interaction between fluid layers in turbulent flow. It measures how dilution of velocity gradients decreases the overall drag force experienced by surfaces in fluid dynamics applications. Understanding the Dilution Index enables precise control of drag reduction techniques in engineering designs such as pipeline transport and aerodynamic surfaces.

Key Differences Between Drag Resistance and Dilution Index

Drag resistance measures the force opposing an object's motion through a fluid, primarily influenced by shape, surface roughness, and velocity, whereas dilution index quantifies the extent of mixing or concentration decrease of a substance in a solvent. Drag resistance is expressed in units of force or drag coefficient, reflecting physical interactions with fluid dynamics, while dilution index is a dimensionless ratio emphasizing concentration gradients in chemical or environmental processes. Understanding drag resistance is crucial for optimizing aerodynamics and hydrodynamics, whereas dilution index informs dilution efficiency and pollutant dispersion.

Factors Influencing Drag Resistance in Fluids

Drag resistance in fluids is primarily influenced by viscosity, velocity, surface roughness, and fluid density. Higher viscosity or increased velocity usually leads to greater drag resistance, while surface texture and turbulence can alter the flow regime, affecting overall resistance. Understanding these factors is crucial for optimizing the dilution index and improving fluid dynamics in various engineering applications.

Determinants of the Dilution Index in Various Systems

The Dilution Index in various systems is primarily influenced by factors such as fluid velocity, temperature, and the physical properties of the medium, including viscosity and density. Drag resistance plays a crucial role by affecting how fluid flows around particles or within channels, thereby altering mixing efficiency and dilution rates. Understanding these determinants helps optimize your system's performance by balancing drag forces and dilution to achieve desired outcomes.

Measurement Techniques: Drag Resistance vs Dilution Index

Drag resistance measurement techniques typically involve wind tunnel testing and computational fluid dynamics (CFD) simulations to evaluate aerodynamic performance by quantifying the force opposing motion. Dilution index, often assessed through tracer gas methods or optical sensors in fluid dynamics, measures mixing efficiency and concentration gradients within a flow field. Both techniques rely on precise instrumentation and data analysis to optimize designs in automotive, aerospace, and environmental engineering applications.

Impact on System Performance: A Comparative Analysis

Drag resistance significantly influences system efficiency by increasing energy consumption and reducing flow rates, while the dilution index measures the extent of mixing, affecting overall process optimization. High drag resistance can slow down system performance, causing bottlenecks, whereas an optimal dilution index ensures thorough blending without excessive turbulence that might impair stability. Understanding the balance between drag resistance and dilution index helps you optimize system design for maximum operational efficiency and minimal energy loss.

Applications Across Industries: Where Each Metric Matters

Drag resistance is crucial in automotive and aerospace industries for optimizing fuel efficiency and vehicle aerodynamics, while the dilution index is essential in chemical and environmental engineering to assess mixing efficiency and pollutant dispersion. In manufacturing, drag resistance helps in designing conveyor systems and fluid transport, whereas dilution index guides wastewater treatment and industrial emissions control. Both metrics drive innovation by enhancing performance and sustainability across diverse engineering applications.

Future Trends in Drag Resistance and Dilution Index Research

Future trends in drag resistance and dilution index research emphasize advanced computational modeling and real-time monitoring technologies to enhance prediction accuracy in pipeline and fluid flow systems. Researchers are increasingly integrating machine learning algorithms to optimize drag reduction strategies and improve dilution index measurements under varying operational conditions. Your ability to leverage these innovations will lead to more efficient industrial processes and reduced energy consumption.

Drag resistance vs dilution index Infographic

libmatt.com

libmatt.com