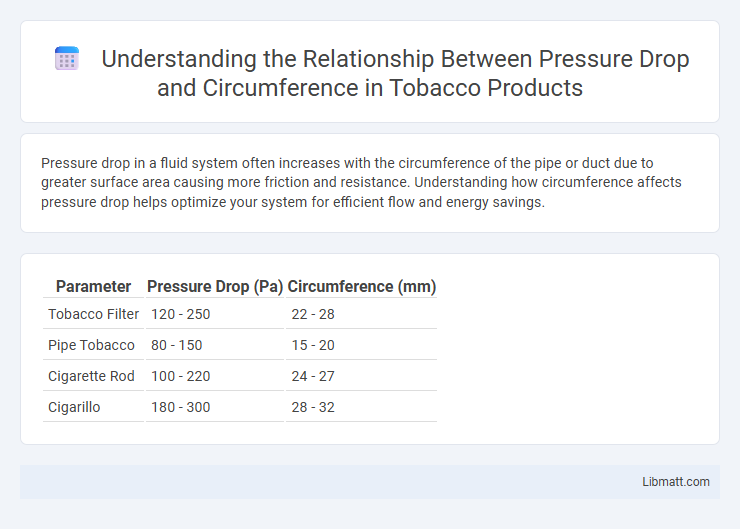

Pressure drop in a fluid system often increases with the circumference of the pipe or duct due to greater surface area causing more friction and resistance. Understanding how circumference affects pressure drop helps optimize your system for efficient flow and energy savings.

Table of Comparison

| Parameter | Pressure Drop (Pa) | Circumference (mm) |

|---|---|---|

| Tobacco Filter | 120 - 250 | 22 - 28 |

| Pipe Tobacco | 80 - 150 | 15 - 20 |

| Cigarette Rod | 100 - 220 | 24 - 27 |

| Cigarillo | 180 - 300 | 28 - 32 |

Understanding Pressure Drop: Key Concepts

Pressure drop refers to the reduction in fluid pressure as it flows through a pipe or duct, primarily influenced by the circumference due to frictional forces acting along the inner surface. Larger circumferences generally decrease pressure drop by providing a greater flow area, reducing velocity and friction losses according to the Darcy-Weisbach equation. Accurately calculating pressure drop relative to circumference is essential for optimizing fluid transport systems and ensuring efficient pump and compressor performance.

The Role of Circumference in Fluid Dynamics

Pressure drop in fluid dynamics is directly influenced by the circumference of the flow pathway, where larger circumferences tend to reduce resistance and lower pressure loss due to increased flow area. The interaction between circumference and fluid velocity affects turbulence levels, with smaller circumferences causing higher velocity and greater pressure drop from frictional forces. Understanding how the circumference impacts pressure drop helps optimize pipe and duct designs to improve your system's efficiency and minimize energy consumption.

Mathematical Relationship: Pressure Drop vs Circumference

The pressure drop across a cylindrical conduit is mathematically related to its circumference through fluid friction factors and flow dynamics, often modeled by the Darcy-Weisbach equation where the hydraulic diameter incorporates circumference measurements. As circumference increases, the wetted perimeter affects the friction factor, influencing the velocity profile and subsequently altering the pressure drop. Understanding this relationship helps you optimize pipe design to minimize energy loss in fluid transport systems.

Factors Affecting Pressure Drop in Pipes and Tubes

Pressure drop in pipes and tubes is primarily influenced by the circumference, which affects fluid velocity and frictional resistance along the flow path. Factors such as pipe diameter, surface roughness, fluid viscosity, and flow rate interact with the circumference to determine the magnitude of pressure loss. Turbulence and pipe length further amplify these effects, leading to increased energy consumption in fluid transport systems.

Circumference Impact on Flow Resistance

Increasing the circumference of a pipe directly influences flow resistance by altering the pressure drop characteristics. Larger circumferences typically reduce velocity for a given flow rate, thereby decreasing pressure drop and enhancing flow efficiency. This relationship is critical in optimizing pipe design for minimizing energy losses in fluid transport systems.

Comparative Analysis: Large vs Small Circumference Systems

Pressure drop in fluid systems significantly varies with circumference size due to changes in flow dynamics and frictional forces. Large circumference systems typically exhibit lower pressure drop per unit length compared to small circumference systems, as the increased cross-sectional area reduces velocity and turbulence. Understanding your system's circumference allows for optimized design, minimizing energy losses and enhancing overall performance.

Design Considerations: Optimizing Circumference to Minimize Pressure Drop

Optimizing the circumference in fluid flow systems is critical to minimizing pressure drop by balancing cross-sectional area and flow velocity. A larger circumference increases the pipe diameter, reducing fluid velocity and frictional losses, which directly lowers pressure drop. Design considerations must include material constraints and spatial limitations to effectively tailor circumference for optimal hydraulic performance.

Real-World Applications: Pressure Drop and Circumference in Engineering

Pressure drop in engineering systems is directly influenced by the circumference of pipes or ducts, as larger circumferences typically reduce flow velocity and minimize energy loss. In real-world applications such as HVAC systems and fluid transport pipelines, optimizing the circumference helps maintain efficient pressure levels and reduces operational costs. Understanding this relationship allows you to design systems that balance material usage with performance requirements effectively.

Experimental Methods for Measuring Pressure Drop Related to Circumference

Experimental methods for measuring pressure drop related to circumference typically involve the use of differential pressure sensors calibrated along various points of a pipe or duct circumference. High-precision manometers or Pitot tubes capture pressure readings at multiple angular positions, enabling detailed mapping of localized pressure losses caused by geometric factors. Data acquisition systems compile these measurements to analyze the correlation between pipe circumference irregularities and resulting pressure drop, providing crucial insights for fluid dynamics optimization.

Innovations and Future Trends in Managing Pressure Drop through Circumference Control

Innovations in managing pressure drop through circumference control include advanced materials and precision machining techniques that optimize pipe and duct diameters to minimize resistance. Future trends involve the integration of smart sensor technologies and AI-driven adaptive systems to dynamically adjust circumference and maintain optimal flow conditions in real time. These advancements aim to enhance energy efficiency and reduce operational costs in fluid transport systems.

Pressure drop vs circumference Infographic

libmatt.com

libmatt.com