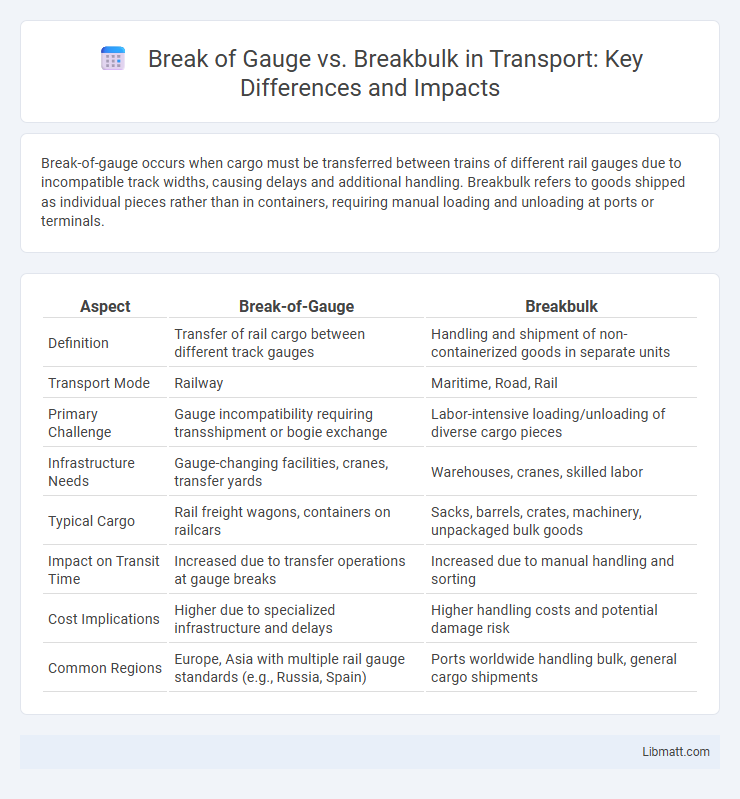

Break-of-gauge occurs when cargo must be transferred between trains of different rail gauges due to incompatible track widths, causing delays and additional handling. Breakbulk refers to goods shipped as individual pieces rather than in containers, requiring manual loading and unloading at ports or terminals.

Table of Comparison

| Aspect | Break-of-Gauge | Breakbulk |

|---|---|---|

| Definition | Transfer of rail cargo between different track gauges | Handling and shipment of non-containerized goods in separate units |

| Transport Mode | Railway | Maritime, Road, Rail |

| Primary Challenge | Gauge incompatibility requiring transshipment or bogie exchange | Labor-intensive loading/unloading of diverse cargo pieces |

| Infrastructure Needs | Gauge-changing facilities, cranes, transfer yards | Warehouses, cranes, skilled labor |

| Typical Cargo | Rail freight wagons, containers on railcars | Sacks, barrels, crates, machinery, unpackaged bulk goods |

| Impact on Transit Time | Increased due to transfer operations at gauge breaks | Increased due to manual handling and sorting |

| Cost Implications | Higher due to specialized infrastructure and delays | Higher handling costs and potential damage risk |

| Common Regions | Europe, Asia with multiple rail gauge standards (e.g., Russia, Spain) | Ports worldwide handling bulk, general cargo shipments |

Introduction to Break-of-Gauge and Breakbulk

Break-of-gauge occurs when rail transport requires transferring goods between different railway gauges, causing delays and increased handling costs. Breakbulk refers to cargo that is loaded and unloaded as individual pieces instead of being containerized, increasing labor and transit times. Both logistics challenges impact supply chain efficiency by requiring additional processes to move goods across incompatible transport modes or packaging types.

Defining Break-of-Gauge in Rail Transportation

Break-of-gauge in rail transportation refers to the point where railway tracks of different gauges meet, requiring the transfer of cargo between trains due to incompatible rail sizes. This transfer creates logistical challenges and often increases handling time and costs compared to breakbulk, which involves manual unloading and reloading of goods without gauge issues. Understanding break-of-gauge is essential for optimizing your rail freight operations across regions with varying track standards.

Understanding Breakbulk Cargo Operations

Breakbulk cargo operations involve handling goods that are loaded individually rather than in containers, requiring specialized equipment and careful coordination at ports. Break-of-gauge refers to the transfer of cargo between different railway track gauges, necessitating transshipment facilities to accommodate incompatible rail systems. Understanding the differences ensures Your logistics planning optimizes efficiency between sea and rail transport modalities.

Key Differences Between Break-of-Gauge and Breakbulk

Break-of-gauge refers to the transfer of cargo between trains of different rail gauges, requiring specialized equipment to handle the gauge change, while breakbulk involves the shipment of goods in individual units such as bags, boxes, or crates rather than in containers. Break-of-gauge processes primarily occur in rail transport due to incompatible track widths, whereas breakbulk applies to maritime and land freight handling where cargo is not containerized. The key difference lies in break-of-gauge addressing infrastructure incompatibilities in railways, contrasting with breakbulk focusing on non-containerized cargo handling across various transport modes.

Challenges Faced in Break-of-Gauge Transshipments

Break-of-gauge transshipments involve transferring cargo between trains of different track gauges, leading to significant logistical challenges such as increased handling time, risk of cargo damage, and higher labor costs. These transshipments require specialized equipment and facilities to efficiently manage the gauge differences, complicating supply chain coordination and reducing overall transit speed. Your operations may face delays and increased expenses compared to breakbulk shipping, which typically handles cargo without such infrastructure constraints.

Common Issues with Breakbulk Cargo Handling

Breakbulk cargo handling often faces challenges such as increased risk of damage due to multiple handling points and inefficient loading methods. Delays in transit may occur because breakbulk shipments require personalized handling and careful coordination of various cargo pieces. Ensuring your logistics team addresses these issues can minimize loss and improve overall shipping efficiency.

Solutions for Efficient Break-of-Gauge Management

Efficient break-of-gauge management relies on advanced transshipment facilities and automated container handling systems to minimize delays and costs associated with transferring cargo between incompatible rail gauges. Implementing standardized loading units and agile logistics software enhances coordination and tracking, ensuring smooth transitions without compromising cargo integrity. Your supply chain benefits from integrated solutions like gauge-changing flatcars and modular cargo designs that streamline operations in break-of-gauge scenarios.

Technologies Advancing Breakbulk Operations

Technologies advancing breakbulk operations include automated cargo handling systems, real-time tracking with IoT sensors, and AI-driven logistics platforms that optimize loading and unloading processes. These innovations enhance efficiency by reducing manual labor and minimizing delays traditionally associated with breakbulk cargo transfer at break-of-gauge points. Your supply chain benefits from improved accuracy and faster turnaround times, crucial for managing complex shipments where standard containerization is not feasible.

Economic Impact of Break-of-Gauge vs Breakbulk

Break-of-gauge significantly increases transportation costs due to the need for transshipment, specialized infrastructure, and potential delays, impacting supply chain efficiency and competitiveness. Breakbulk cargo, while labor-intensive and time-consuming, offers flexibility in handling non-containerized goods but incurs higher labor costs and risks of damage. Economically, break-of-gauge challenges often require substantial investment in intermodal terminals and equipment, whereas breakbulk handling affects port throughput and labor market dynamics, influencing overall trade cost structures.

Future Trends in Freight Logistics: Break-of-Gauge and Breakbulk

Break-of-gauge and breakbulk logistics face transformation driven by automation and digital integration, enhancing efficiency and reducing transit times in freight transport. Advanced tracking systems and AI-powered handling solutions optimize the transshipment process, addressing challenges inherent in gauge differences and bulk cargo handling. Your supply chain stands to benefit from these innovations through increased reliability and cost-effectiveness in multimodal freight operations.

break-of-gauge vs breakbulk Infographic

libmatt.com

libmatt.com