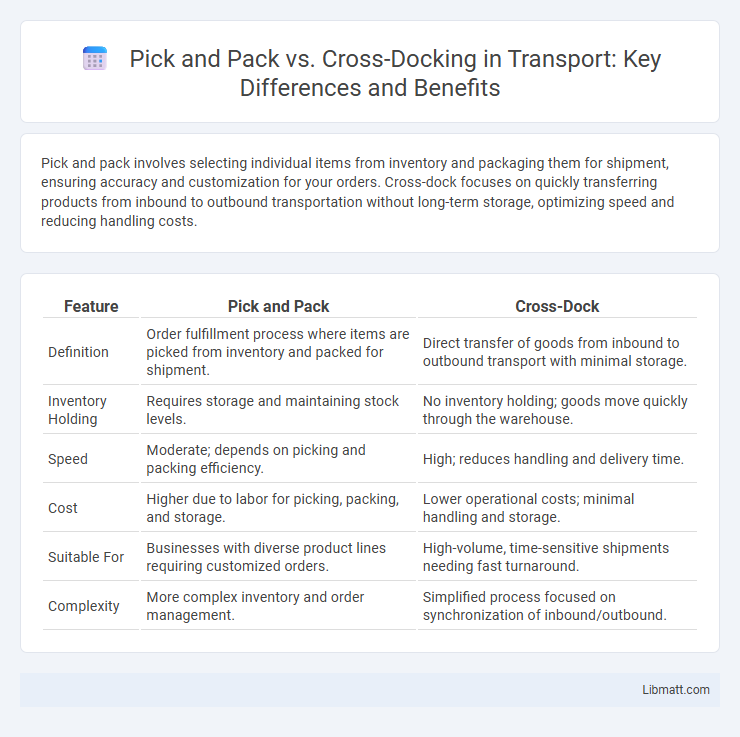

Pick and pack involves selecting individual items from inventory and packaging them for shipment, ensuring accuracy and customization for your orders. Cross-dock focuses on quickly transferring products from inbound to outbound transportation without long-term storage, optimizing speed and reducing handling costs.

Table of Comparison

| Feature | Pick and Pack | Cross-Dock |

|---|---|---|

| Definition | Order fulfillment process where items are picked from inventory and packed for shipment. | Direct transfer of goods from inbound to outbound transport with minimal storage. |

| Inventory Holding | Requires storage and maintaining stock levels. | No inventory holding; goods move quickly through the warehouse. |

| Speed | Moderate; depends on picking and packing efficiency. | High; reduces handling and delivery time. |

| Cost | Higher due to labor for picking, packing, and storage. | Lower operational costs; minimal handling and storage. |

| Suitable For | Businesses with diverse product lines requiring customized orders. | High-volume, time-sensitive shipments needing fast turnaround. |

| Complexity | More complex inventory and order management. | Simplified process focused on synchronization of inbound/outbound. |

Understanding Pick and Pack: Definition and Process

Pick and pack is a crucial order fulfillment process where items are selected from inventory (picking) and then packaged for shipping (packing). Efficient pick and pack operations ensure accuracy and speed by organizing inventory locations and using technology like barcode scanners or warehouse management systems. Your ability to optimize pick and pack processes directly impacts delivery times and customer satisfaction in e-commerce and retail distribution.

Exploring Cross-Docking: How It Works

Cross-docking streamlines supply chain operations by directly transferring products from inbound to outbound transportation without long-term storage, reducing handling and storage costs. This method minimizes inventory holding times and accelerates order fulfillment compared to traditional pick and pack systems that require detailed item selection and packing. Your business can achieve faster delivery times and lower operational expenses by implementing efficient cross-docking processes.

Key Differences Between Pick and Pack and Cross-Docking

Pick and pack involves selecting individual items from inventory and packaging them for shipment, optimizing order accuracy and customization. Cross-docking focuses on the rapid transfer of goods from inbound to outbound transportation with minimal storage, reducing handling time and inventory holding costs. Your choice depends on whether you prioritize order personalization through pick and pack or speed and efficiency through cross-docking.

Advantages of Pick and Pack in Modern Warehousing

Pick and pack offers precise order fulfillment by allowing warehouses to customize shipments per customer needs, enhancing accuracy and reducing errors. It improves inventory control through detailed tracking of individual items, enabling real-time stock visibility and faster response to demand fluctuations. This method also supports scalability in e-commerce operations by efficiently handling diverse product assortments and high order volumes.

Benefits of Cross-Docking for Supply Chain Efficiency

Cross-docking minimizes inventory holding costs by transferring products directly from inbound to outbound transportation, reducing storage time and handling. This process accelerates order fulfillment, leading to faster delivery and improved customer satisfaction. Enhanced supply chain efficiency is achieved through streamlined workflows, reduced labor expenses, and optimized warehouse space utilization.

Suitable Use Cases for Pick and Pack vs Cross-Docking

Pick and pack is ideal for e-commerce businesses handling customized orders, allowing precise selection and packaging of individual items before shipping. Cross-docking suits high-volume, fast-moving goods with minimal storage needs, enabling rapid transfer from inbound to outbound trucks to reduce holding costs. Understanding your supply chain's demand variability and order complexity helps determine whether pick and pack or cross-docking optimizes efficiency and delivery speed.

Cost Implications: Pick and Pack vs Cross-Dock

Pick and pack operations often incur higher labor and storage costs due to individual order processing and inventory holding requirements. Cross-dock logistics minimize warehousing expenses by transferring goods directly from inbound to outbound transportation, reducing handling time and associated costs. Understanding these cost implications can help you optimize supply chain efficiency and reduce overall operational expenses.

Impact on Delivery Speed and Customer Satisfaction

Pick and pack processes involve individually selecting and packaging items, which can extend handling time but ensures order accuracy and customization, directly enhancing customer satisfaction. Cross-dock strategies minimize storage time by unloading inbound products directly onto outbound shipments, significantly boosting delivery speed and reducing lead times. Your choice between these methods influences the balance between rapid delivery and precise order fulfillment, impacting overall customer experience.

Technology and Automation in Pick and Pack and Cross-Dock

Pick and pack operations leverage advanced warehouse management systems (WMS) and automated picking technologies such as robotics and barcode scanning to increase accuracy and efficiency in order fulfillment. Cross-dock facilities utilize real-time inventory tracking and conveyor systems to facilitate rapid sorting and direct transfer of goods, minimizing storage time and handling costs. Both methods benefit from integrated automation that streamlines workflow, reduces manual labor, and accelerates supply chain responsiveness.

Choosing the Right Fulfillment Strategy for Your Business

Pick and pack fulfillment involves selecting and packaging products from inventory to fulfill specific customer orders, making it ideal for businesses with diverse SKUs and customized orders. Cross-docking streamlines operations by unloading incoming goods directly onto outbound shipments, minimizing storage time and reducing handling costs, which suits high-volume, fast-moving products. Your choice between these strategies depends on your order complexity, inventory turnover rate, and shipping speed requirements to optimize supply chain efficiency.

pick and pack vs cross-dock Infographic

libmatt.com

libmatt.com