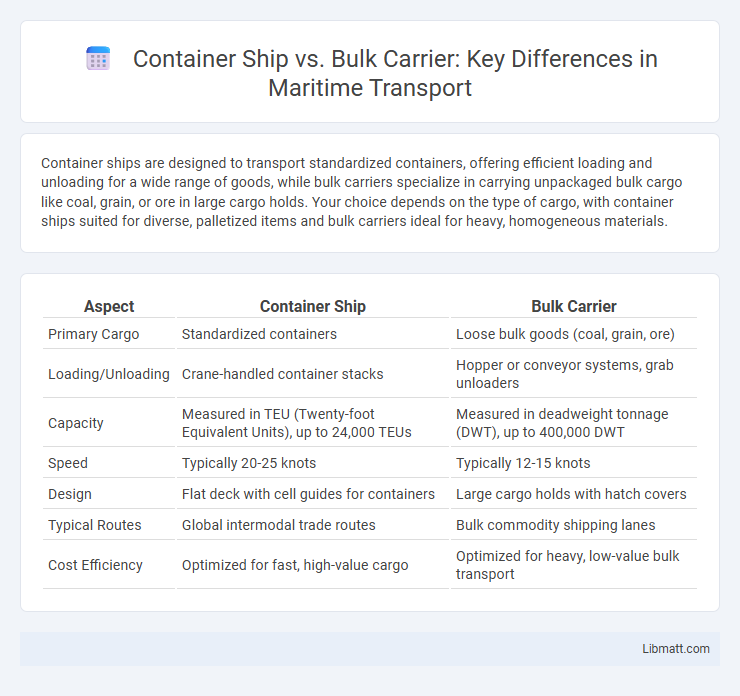

Container ships are designed to transport standardized containers, offering efficient loading and unloading for a wide range of goods, while bulk carriers specialize in carrying unpackaged bulk cargo like coal, grain, or ore in large cargo holds. Your choice depends on the type of cargo, with container ships suited for diverse, palletized items and bulk carriers ideal for heavy, homogeneous materials.

Table of Comparison

| Aspect | Container Ship | Bulk Carrier |

|---|---|---|

| Primary Cargo | Standardized containers | Loose bulk goods (coal, grain, ore) |

| Loading/Unloading | Crane-handled container stacks | Hopper or conveyor systems, grab unloaders |

| Capacity | Measured in TEU (Twenty-foot Equivalent Units), up to 24,000 TEUs | Measured in deadweight tonnage (DWT), up to 400,000 DWT |

| Speed | Typically 20-25 knots | Typically 12-15 knots |

| Design | Flat deck with cell guides for containers | Large cargo holds with hatch covers |

| Typical Routes | Global intermodal trade routes | Bulk commodity shipping lanes |

| Cost Efficiency | Optimized for fast, high-value cargo | Optimized for heavy, low-value bulk transport |

Introduction to Container Ships and Bulk Carriers

Container ships are specialized vessels designed to transport standardized cargo containers efficiently across oceans, featuring a large hull space optimized for stacking containers securely. Bulk carriers, in contrast, are engineered to carry unpackaged bulk commodities such as coal, grain, and ore in large cargo holds with minimal structural divisions. The fundamental difference lies in cargo type and handling methods, with container ships facilitating faster loading and unloading using cranes, while bulk carriers rely on cranes or conveyor systems suited for bulk materials.

Key Differences in Ship Design

Container ships feature a cellular structure with large open holds and standardized rectangular bays designed to stack containers efficiently, whereas bulk carriers have large, unobstructed cargo holds to transport unpackaged bulk commodities like coal, grain, or ore. The hull of container ships is optimized for speed and stability during container loading and unloading, while bulk carriers prioritize structural reinforcement to handle heavy, dense cargo. Your choice between these vessels depends on the cargo type, with container ships suitable for packaged goods and bulk carriers designed for raw materials.

Cargo Types and Handling Methods

Container ships transport standardized containers filled with manufactured goods, electronics, and perishable items, enabling efficient loading and unloading through crane systems and straddle carriers. Bulk carriers handle unpackaged bulk commodities such as coal, grain, ore, and cement, relying on specialized conveyor belts, grabs, or pneumatic systems for cargo handling. Your choice between these vessels depends on the cargo type and the loading facilities available at the port.

Loading and Unloading Mechanisms

Container ships utilize gantry cranes and specialized container handling equipment enabling fast and efficient loading and unloading of standardized containers stacked in rows. Bulk carriers rely on conveyor belts, grabs, and cranes designed to handle loose cargo like coal, grain, or ore, which requires more time-consuming and labor-intensive processes. The standardized container system of container ships allows for quicker turnaround times compared to the often slower bulk cargo handling methods on bulk carriers.

Operational Efficiency and Speed

Container ships typically achieve higher operational efficiency and faster transit speeds due to their streamlined loading and unloading processes using standardized containers, allowing rapid turnaround times at ports. Bulk carriers, designed for transporting unpackaged bulk cargo such as coal or grain, generally operate at slower speeds because of heavier cargo loads and less automated handling, resulting in longer port stays and slower voyage speeds. The speed advantage of container ships often translates into shorter delivery times and improved supply chain reliability compared to bulk carriers.

Cost Comparison and Economics

Container ships generally have higher initial construction costs due to advanced loading technology and container handling systems, but they benefit from faster turnaround times and greater operational efficiency. Bulk carriers typically incur lower capital expenses and simplified maintenance costs but face higher per-unit shipping expenses because of slower loading and unloading processes. Economies of scale favor container ships for high-value, time-sensitive cargo, while bulk carriers remain cost-effective for transporting large volumes of homogeneous commodities like coal, grain, or ore.

Global Trade Routes and Deployment

Container ships dominate major global trade routes such as the Asia-Europe and trans-Pacific corridors, efficiently transporting manufactured goods in standardized containers designed for rapid loading and unloading. Bulk carriers primarily navigate resource-rich regions like Australia, Brazil, and West Africa, transporting raw materials such as coal, iron ore, and grain along long-haul trade routes to industrial hubs. Your choice between container ships and bulk carriers depends on the type of cargo and the strategic deployment across key maritime corridors shaping global supply chains.

Environmental Impact and Sustainability

Container ships and bulk carriers differ significantly in environmental impact and sustainability, with container ships typically having higher fuel consumption due to faster speeds and frequent port calls, increasing greenhouse gas emissions. Bulk carriers operate at slower speeds and carry dense cargoes like coal, iron ore, and grains, leading to relatively lower emissions per ton-mile but still contributing to air and water pollution through ballast water discharge and structural corrosion. To improve your environmental footprint, selecting ships with advanced emission control technologies and participating in sustainable shipping practices is essential.

Safety Considerations and Risks

Container ships face unique safety considerations due to the risk of container loss overboard and fire hazards within stacked containers, necessitating stringent securing and monitoring protocols. Bulk carriers encounter risks related to cargo shifting, structural stress, and potential liquefaction of certain bulk materials, which can compromise vessel stability. Both vessel types require rigorous maintenance and adherence to international safety regulations such as SOLAS and MARPOL to mitigate navigational and environmental hazards.

Future Trends in Shipping Industry

Container ships are increasingly adopting digitalization and automation technologies, driving efficiency and reducing environmental impact through alternative fuels like LNG and hydrogen. Bulk carriers are also evolving with enhanced cargo handling systems and eco-friendly designs to meet stringent emission regulations and growing demand for sustainable shipping. Both vessel types are crucial in the shift toward smart shipping solutions and decarbonization strategies in the global maritime industry.

container ship vs bulk carrier Infographic

libmatt.com

libmatt.com