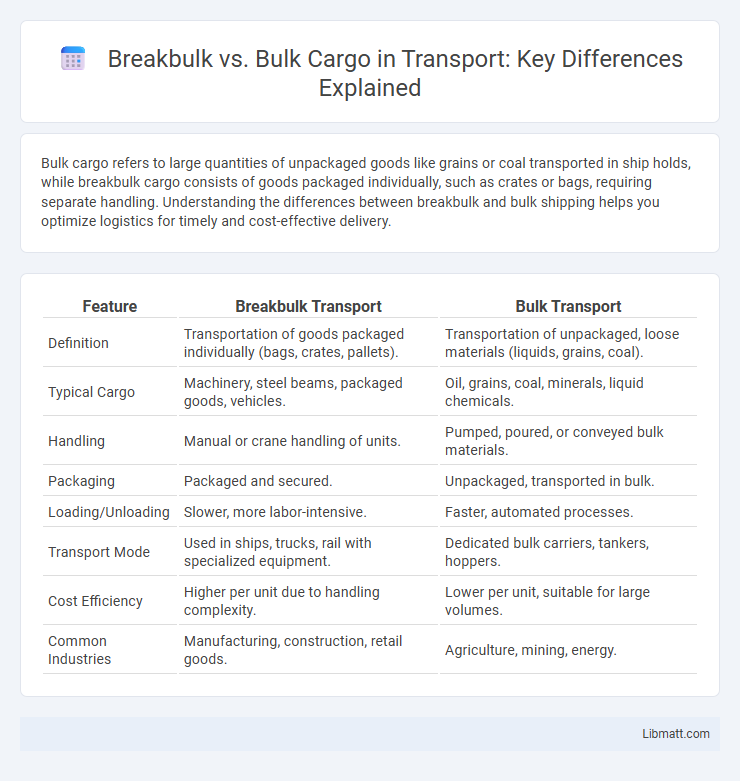

Bulk cargo refers to large quantities of unpackaged goods like grains or coal transported in ship holds, while breakbulk cargo consists of goods packaged individually, such as crates or bags, requiring separate handling. Understanding the differences between breakbulk and bulk shipping helps you optimize logistics for timely and cost-effective delivery.

Table of Comparison

| Feature | Breakbulk Transport | Bulk Transport |

|---|---|---|

| Definition | Transportation of goods packaged individually (bags, crates, pallets). | Transportation of unpackaged, loose materials (liquids, grains, coal). |

| Typical Cargo | Machinery, steel beams, packaged goods, vehicles. | Oil, grains, coal, minerals, liquid chemicals. |

| Handling | Manual or crane handling of units. | Pumped, poured, or conveyed bulk materials. |

| Packaging | Packaged and secured. | Unpackaged, transported in bulk. |

| Loading/Unloading | Slower, more labor-intensive. | Faster, automated processes. |

| Transport Mode | Used in ships, trucks, rail with specialized equipment. | Dedicated bulk carriers, tankers, hoppers. |

| Cost Efficiency | Higher per unit due to handling complexity. | Lower per unit, suitable for large volumes. |

| Common Industries | Manufacturing, construction, retail goods. | Agriculture, mining, energy. |

Understanding Breakbulk and Bulk Cargo

Breakbulk cargo consists of goods transported in individual units such as crates, bags, or barrels that require manual handling and separate loading, while bulk cargo refers to large quantities of unpackaged materials like grains, coal, or liquids transported in specialized containers or tanks. Understanding the differences between breakbulk and bulk cargo is essential for optimizing your shipping strategy, as breakbulk offers flexibility for varied cargo types but involves higher handling costs compared to the efficiency and lower expense of bulk shipments. Choosing the appropriate cargo method impacts logistics, storage requirements, and overall transportation efficiency.

Key Differences Between Breakbulk and Bulk Shipping

Breakbulk shipping involves transporting goods packaged in bags, boxes, crates, or drums, handled individually during loading and unloading, while bulk shipping refers to the transportation of unpackaged commodities like coal, grain, or oil in large quantities. Breakbulk cargo is typically moved via containers or pallets, requiring specialized handling equipment, whereas bulk cargo is loaded directly into the ship's hold using conveyor belts, grabs, or pipelines. The main differences lie in cargo packaging, handling methods, and port infrastructure, influencing shipping costs, transit times, and risk of damage.

Types of Breakbulk Cargo

Breakbulk cargo consists of individually loaded units such as bags, boxes, crates, drums, or pallets, each requiring separate handling during shipping. Common types of breakbulk cargo include steel coils, machinery, timber, and packaged goods that cannot be containerized due to size or shape. Understanding your cargo type helps optimize logistics for breakbulk shipping, ensuring safer transport and reducing handling costs compared to bulk cargo, which moves unpackaged in large quantities like grains or coal.

Types of Bulk Cargo

Bulk cargo is primarily categorized into dry bulk and liquid bulk, each with distinct handling and transportation methods. Dry bulk includes commodities such as grains, coal, ores, and cement, typically transported loose in ship holds. Liquid bulk cargo covers substances like crude oil, chemicals, and liquefied natural gas, requiring specialized tankers designed to prevent contamination and spillage.

Common Industries Utilizing Breakbulk vs Bulk

Common industries utilizing breakbulk cargo include construction, machinery, and steel production, where large, heavy items like pipes, machinery parts, and steel coils require specialized handling. Bulk cargo transportation is prevalent in agriculture, mining, and energy sectors, moving commodities such as grain, coal, and crude oil in large quantities without packaging. Breakbulk shipping supports projects needing custom loads, while bulk shipping focuses on high-volume, homogeneous goods for processing and consumption.

Handling and Logistics Challenges

Breakbulk cargo requires specialized handling equipment and labor-intensive processes due to its non-containerized, varied-sized units, increasing loading and unloading times. Bulk cargo, often consisting of homogeneous materials like grains or minerals, necessitates specialized conveyance systems such as conveyor belts or pumps, posing challenges related to spillage and contamination. Both cargo types demand tailored logistics strategies to optimize storage, transportation, and risk management in port and shipping operations.

Cost Comparison: Breakbulk vs Bulk Shipping

Breakbulk shipping generally incurs higher costs compared to bulk shipping due to more complex handling, packaging, and labor requirements for individual cargo pieces. Bulk shipping benefits from economies of scale by transporting large quantities of unpackaged goods like grains or minerals, reducing per-unit expenses significantly. Your choice between breakbulk and bulk shipping directly impacts overall transportation cost efficiency depending on cargo type and shipment size.

Environmental Impact and Safety Considerations

Breakbulk cargo, typically shipped in smaller units such as crates or pallets, tends to generate more packaging waste and requires more handling, increasing environmental impact and risk of damage. Bulk cargo, transported unpackaged in large quantities like grains or minerals, minimizes packaging waste but poses higher risks of spillage, dust emissions, and challenging containment, affecting both environmental safety and worker health. Safety considerations for breakbulk involve managing numerous handling points to reduce accidents, whereas bulk transport demands strict controls to prevent hazardous material leaks and ensure vessel stability.

Technology and Equipment Used in Each Method

Breakbulk cargo handling relies on cranes, forklifts, and pallet jacks to manage individually packaged items, optimizing flexibility for diverse shipment sizes and shapes. Bulk cargo transport employs specialized conveyor systems, pneumatic equipment, and large-scale hoppers designed for efficient loading and unloading of loose materials like grains, coal, or minerals. Your choice between breakbulk and bulk methods depends on the compatibility of your cargo with these tailored technologies and equipment efficiencies.

Choosing the Right Shipping Method: Factors to Consider

Choosing the right shipping method between breakbulk and bulk cargo depends on factors such as cargo type, size, and handling requirements. Breakbulk shipping suits oversized or irregular goods requiring individual handling, while bulk shipping is ideal for large quantities of homogeneous commodities like grains or coal. Consider port infrastructure, cost efficiency, and delivery timelines to optimize logistics and ensure safe, timely transportation.

breakbulk vs bulk Infographic

libmatt.com

libmatt.com