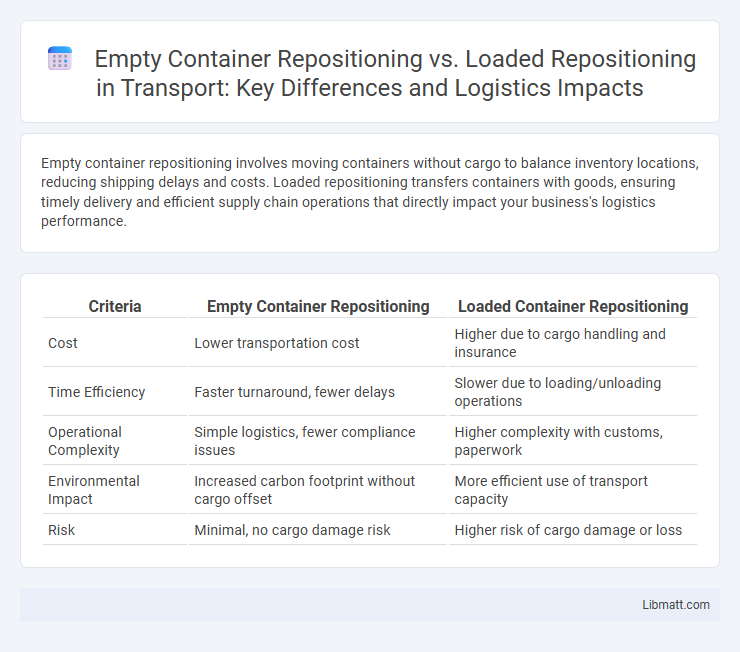

Empty container repositioning involves moving containers without cargo to balance inventory locations, reducing shipping delays and costs. Loaded repositioning transfers containers with goods, ensuring timely delivery and efficient supply chain operations that directly impact your business's logistics performance.

Table of Comparison

| Criteria | Empty Container Repositioning | Loaded Container Repositioning |

|---|---|---|

| Cost | Lower transportation cost | Higher due to cargo handling and insurance |

| Time Efficiency | Faster turnaround, fewer delays | Slower due to loading/unloading operations |

| Operational Complexity | Simple logistics, fewer compliance issues | Higher complexity with customs, paperwork |

| Environmental Impact | Increased carbon footprint without cargo offset | More efficient use of transport capacity |

| Risk | Minimal, no cargo damage risk | Higher risk of cargo damage or loss |

Introduction to Container Repositioning

Container repositioning involves moving shipping containers to locations where they are in demand, essential for maintaining global supply chain efficiency. Empty container repositioning specifically addresses the challenge of relocating unused containers to ports with high export volume, reducing imbalances caused by trade flow discrepancies. Loaded container repositioning focuses on transporting cargo-filled containers to meet import demand while optimizing fleet utilization and minimizing costs.

Understanding Empty Container Repositioning

Empty container repositioning involves transporting vacant shipping containers to locations with high demand, optimizing logistics to reduce demurrage costs and improve asset utilization. Unlike loaded repositioning, which moves containers with cargo, empty repositioning requires strategic planning to balance supply and demand across global ports, minimizing unnecessary transport expenses. Effective empty container repositioning leverages real-time data and predictive analytics to streamline operations and enhance global supply chain efficiency.

Overview of Loaded Container Repositioning

Loaded container repositioning involves transporting containers with cargo from one location to another, optimizing supply chain efficiency by aligning container availability with actual demand. This process reduces empty miles and improves cost-effectiveness by maximizing revenue-generating trips, as opposed to moving empty containers without cargo. Understanding your logistics needs can help determine when loaded repositioning is the most strategic choice to enhance operational productivity.

Key Differences between Empty and Loaded Repositioning

Empty container repositioning involves relocating vacant containers to locations with high demand to optimize asset utilization and reduce storage costs, whereas loaded repositioning deals with moving cargo-filled containers, prioritizing delivery schedules and cargo safety. The operational challenges for empty repositioning focus on cost efficiency and inventory management, while loaded repositioning requires strict adherence to transit timelines and handling regulations. Furthermore, empty repositioning typically allows more flexibility in routing compared to the rigid schedules essential for loaded container transport.

Cost Implications: Empty vs Loaded Moves

Empty container repositioning incurs higher per-unit costs due to transportation inefficiencies, as vessels or trucks carry non-revenue-generating assets. Loaded repositioning maximizes operational efficiency by transporting goods and generating freight revenue, reducing the overall cost impact on your supply chain. Understanding these cost implications helps optimize logistics strategies and improve profitability.

Operational Efficiency in Repositioning

Empty container repositioning requires precise planning to minimize unnecessary moves and storage costs, directly impacting operational efficiency by reducing idle container time. Loaded repositioning demands careful coordination to optimize route planning and cargo scheduling, ensuring timely deliveries and maximizing asset utilization. Your operational efficiency improves when both repositioning strategies integrate real-time data analytics and predictive modeling to streamline container flow.

Environmental Impact Comparison

Empty container repositioning generates higher environmental impact due to increased fuel consumption and greenhouse gas emissions per unit transported compared to loaded repositioning, which maximizes cargo capacity utilization. Shipping companies implementing efficient loaded repositioning strategies reduce carbon footprints by minimizing unnecessary voyages and optimizing container logistics. Your supply chain's sustainability improves significantly when prioritizing loaded container movements over empty repositioning.

Technological Solutions for Repositioning

Technological solutions for empty container repositioning leverage advanced tracking systems, predictive analytics, and automated logistics platforms to optimize the movement and availability of containers based on real-time demand and supply data. Loaded repositioning technologies incorporate IoT sensors, blockchain for transparency, and AI-driven route optimization to enhance efficiency by minimizing transit times and ensuring container utilization while in active shipment. Both approaches utilize integrated digital ecosystems to improve operational visibility, reduce costs, and support just-in-time container management across global supply chains.

Challenges and Solutions in Container Repositioning

Empty container repositioning faces challenges such as increased operational costs, underutilized transport capacity, and imbalanced trade routes resulting in inefficient logistics. Loaded container repositioning encounters complexities tied to customs regulations, cargo security, and scheduling conflicts that impact timely deliveries. Solutions emphasize advanced data analytics for route optimization, intermodal transport integration, and collaborative platforms to enhance asset utilization and reduce repositioning costs.

Future Trends in Container Repositioning

Future trends in container repositioning emphasize advanced digital platforms leveraging AI and big data to optimize both empty container repositioning and loaded container repositioning, reducing operational costs and carbon emissions. Blockchain technology is expected to enhance transparency and traceability, improving the efficiency of global supply chains by streamlining documentation for cargo movement. You can anticipate increased automation in port facilities and growth in sustainable practices, ensuring smarter and greener container logistics.

empty container repositioning vs loaded repositioning Infographic

libmatt.com

libmatt.com