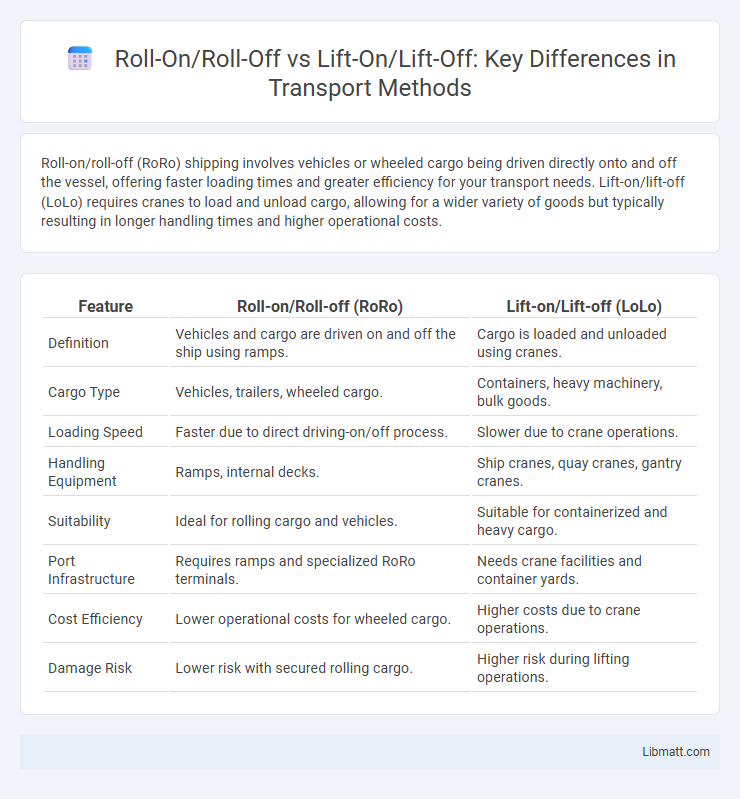

Roll-on/roll-off (RoRo) shipping involves vehicles or wheeled cargo being driven directly onto and off the vessel, offering faster loading times and greater efficiency for your transport needs. Lift-on/lift-off (LoLo) requires cranes to load and unload cargo, allowing for a wider variety of goods but typically resulting in longer handling times and higher operational costs.

Table of Comparison

| Feature | Roll-on/Roll-off (RoRo) | Lift-on/Lift-off (LoLo) |

|---|---|---|

| Definition | Vehicles and cargo are driven on and off the ship using ramps. | Cargo is loaded and unloaded using cranes. |

| Cargo Type | Vehicles, trailers, wheeled cargo. | Containers, heavy machinery, bulk goods. |

| Loading Speed | Faster due to direct driving-on/off process. | Slower due to crane operations. |

| Handling Equipment | Ramps, internal decks. | Ship cranes, quay cranes, gantry cranes. |

| Suitability | Ideal for rolling cargo and vehicles. | Suitable for containerized and heavy cargo. |

| Port Infrastructure | Requires ramps and specialized RoRo terminals. | Needs crane facilities and container yards. |

| Cost Efficiency | Lower operational costs for wheeled cargo. | Higher costs due to crane operations. |

| Damage Risk | Lower risk with secured rolling cargo. | Higher risk during lifting operations. |

Introduction to Roll-On/Roll-Off (RoRo) and Lift-On/Lift-Off (LoLo) Shipping

Roll-On/Roll-Off (RoRo) shipping involves vessels designed to carry wheeled cargo such as cars, trucks, and trailers that are driven directly on and off the ship via ramps, enabling fast and efficient loading and unloading. Lift-On/Lift-Off (LoLo) shipping relies on cranes to load and unload cargo containers or heavy goods, offering versatility for various types of freight but requiring port equipment. Your choice between RoRo and LoLo depends on the nature of your cargo and infrastructure at origin and destination ports.

Key Differences Between RoRo and LoLo Operations

RoRo (Roll-on/Roll-off) operations involve vehicles rolling directly on and off the vessel via ramps, enabling faster loading and unloading compared to LoLo (Lift-on/Lift-off) operations, which require cranes to lift cargo containers or heavy equipment on and off the ship. RoRo is ideal for wheeled cargo such as cars, trucks, and trailers, reducing cargo handling damage and turnaround time, while LoLo is suited for containerized and irregularly shaped cargo requiring precise placement. The infrastructure requirements also differ significantly: RoRo ports need specialized ramps and parking decks, whereas LoLo ports require gantry cranes and extensive container yards for efficient handling.

Advantages of Roll-On/Roll-Off Transport

Roll-On/Roll-Off (RoRo) transport offers significant advantages, including faster loading and unloading processes since vehicles can be driven directly onto and off the vessel, reducing turnaround times. This method minimizes the need for heavy lifting equipment, lowering operational costs and enhancing safety during cargo handling. You benefit from increased efficiency and reliability, especially when transporting wheeled cargo such as cars, trucks, and trailers.

Benefits of Lift-On/Lift-Off Shipping

Lift-on/lift-off (LoLo) shipping offers significant flexibility by allowing cargo to be loaded and unloaded using cranes, making it ideal for heavy, oversized, or non-containerized goods. This method enhances port accessibility, enabling your shipments to reach terminals without specialized roll-on/roll-off (RoRo) ramps. The precision and control in handling reduce damage risks and improve the safety and security of valuable cargo during transit.

Cargo Types Suited for RoRo vs LoLo

Roll-on/roll-off (RoRo) vessels are ideal for wheeled cargo such as cars, trucks, trailers, and heavy machinery that can be driven on and off the ship, offering efficient handling for vehicles and rolling stock. Lift-on/lift-off (LoLo) ships accommodate containerized, breakbulk, and project cargo that require cranes for loading and unloading, making them suitable for diverse freight including steel, timber, and large equipment. Your choice between RoRo and LoLo depends on whether your cargo is primarily self-propelled or requires crane handling to ensure optimal transport efficiency.

Infrastructure and Equipment Requirements

Roll-on/roll-off (RoRo) terminals require specialized ramps and extensive parking areas to facilitate the direct driving of vehicles on and off the vessel, optimizing the loading and unloading process for wheeled cargo. Lift-on/lift-off (LoLo) terminals depend heavily on cranes and container-handling equipment, demanding strong dock infrastructure and substantial yard space for stacking and moving containers. Your choice between RoRo and LoLo should consider the availability of suitable infrastructure, equipment investment, and operational efficiency for the specific cargo type.

Environmental Impact: RoRo vs LoLo

Roll-on/roll-off (RoRo) shipping typically generates lower emissions per ton-mile due to its faster loading and unloading processes, reducing ship idling time and fuel consumption compared to lift-on/lift-off (LoLo) methods. LoLo operations often require additional handling equipment like cranes, increasing energy use and emissions during cargo transfers, impacting environmental efficiency. Optimizing port logistics and equipment in both methods can further mitigate the environmental footprint by minimizing congestion and enhancing fuel efficiency.

Cost Considerations and Efficiency

Roll-on/roll-off (RoRo) shipping significantly reduces labor and equipment costs by allowing vehicles and wheeled cargo to be driven directly onto and off the vessel, minimizing loading times and enhancing turnaround efficiency. Lift-on/lift-off (LoLo) operations require cranes and additional handling, resulting in higher operational expenses and longer port stays due to manual loading and unloading processes. Your choice between RoRo and LoLo should weigh cargo type and frequency against cost savings and loading efficiency for optimal supply chain management.

Safety and Security in RoRo and LoLo Shipping

Safety and security in Roll-on/Roll-off (RoRo) shipping emphasize the secure fastening of wheeled cargo to prevent shifting during transit, reducing the risk of accidents and damage. Lift-on/Lift-off (LoLo) shipping prioritizes container stacking protocols and crane operation safety, ensuring cargo integrity through standardized handling procedures. Both methods implement advanced tracking systems and compliance with international maritime safety regulations to enhance security throughout the shipping process.

Future Trends in Maritime Cargo Handling

Future trends in maritime cargo handling emphasize increased automation and digitalization for both roll-on/roll-off (RoRo) and lift-on/lift-off (LoLo) operations, enhancing efficiency and safety. Innovations such as autonomous cranes and AI-powered logistics are set to optimize cargo flow and reduce turnaround times at ports. Your shipping strategy can benefit by integrating smart technologies that cater to the specific handling requirements of RoRo and LoLo cargo, ensuring competitive advantage in evolving global trade environments.

roll-on/roll-off vs lift-on/lift-off Infographic

libmatt.com

libmatt.com