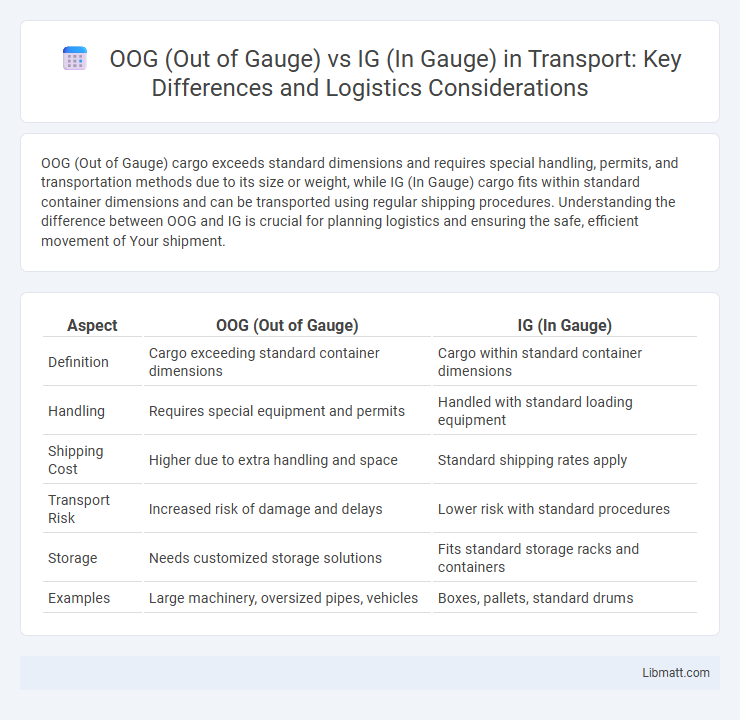

OOG (Out of Gauge) cargo exceeds standard dimensions and requires special handling, permits, and transportation methods due to its size or weight, while IG (In Gauge) cargo fits within standard container dimensions and can be transported using regular shipping procedures. Understanding the difference between OOG and IG is crucial for planning logistics and ensuring the safe, efficient movement of Your shipment.

Table of Comparison

| Aspect | OOG (Out of Gauge) | IG (In Gauge) |

|---|---|---|

| Definition | Cargo exceeding standard container dimensions | Cargo within standard container dimensions |

| Handling | Requires special equipment and permits | Handled with standard loading equipment |

| Shipping Cost | Higher due to extra handling and space | Standard shipping rates apply |

| Transport Risk | Increased risk of damage and delays | Lower risk with standard procedures |

| Storage | Needs customized storage solutions | Fits standard storage racks and containers |

| Examples | Large machinery, oversized pipes, vehicles | Boxes, pallets, standard drums |

Understanding OOG (Out of Gauge) Cargo

OOG (Out of Gauge) cargo refers to goods that exceed the standard dimensions or weight limits for container shipping, requiring special handling, equipment, or permits. Unlike IG (In Gauge) cargo, which fits within standardized container sizes and is easier to load and secure, OOG cargo demands precise planning to ensure safe transport and compliance with regulations. Effective management of OOG shipments involves customized logistics solutions such as flat racks, open-top containers, or breakbulk methods to accommodate oversized or heavy freight.

Defining IG (In Gauge) Cargo

IG (In Gauge) cargo refers to shipments that fit within the standard dimensions of a container or transport vehicle, allowing for straightforward loading and secure stowage. Your IG cargo typically adheres to the height, width, and length limits specified by shipping containers, ensuring efficient handling and cost-effective transportation. This type of cargo contrasts with OOG (Out of Gauge), which requires special handling due to oversized or irregular dimensions.

Key Differences Between OOG and IG Shipments

OOG (Out of Gauge) shipments refer to cargo that exceeds the standard dimensions of a shipping container, requiring special handling, equipment, and routes, while IG (In Gauge) shipments conform to container size limits and are transported using regular containers. OOG cargo often includes heavy machinery, vehicles, or oversized equipment that cannot be disassembled, leading to higher transportation costs and longer transit times due to complex logistics. In contrast, IG shipments benefit from streamlined loading, standardized handling procedures, and cost-effective transport, making them the preferred option for most commodities.

Advantages of Shipping In Gauge Cargo

Shipping In Gauge (IG) cargo ensures compatibility with standard container dimensions, enabling efficient stacking, handling, and transport across global logistics networks. IG cargo minimizes the risk of additional loading charges, delays, and special equipment requirements often associated with Out of Gauge (OOG) shipments. This results in streamlined customs clearance, reduced freight costs, and enhanced overall supply chain reliability.

Challenges with Out of Gauge Shipping

Out of Gauge (OOG) shipping involves transporting cargo that exceeds standard container dimensions, presenting significant logistical challenges such as securing oversized loads, ensuring transportation route compatibility, and adhering to regulatory restrictions. Unlike In Gauge (IG) cargo, which fits within container limits and benefits from standardized handling and stacking procedures, OOG shipments require specialized equipment like flat racks or open-top containers and often demand custom permits. Your supply chain may face increased costs, delays, and complexity due to these factors, necessitating thorough planning and coordination with freight forwarders experienced in OOG logistics.

Equipment Used for OOG vs IG Cargo

OOG (Out of Gauge) cargo requires specialized equipment such as flat racks, open-top containers, extendable trailers, and heavy-duty cranes designed to handle oversized and irregularly shaped loads safely. In contrast, IG (In Gauge) cargo typically utilizes standard shipping containers like 20-foot or 40-foot dry containers, along with conventional forklifts, pallet jacks, and reach stackers suitable for uniform and stackable goods. Selecting the appropriate equipment directly impacts the efficiency and safety of loading, transporting, and unloading cargo based on its dimensional requirements.

Cost Implications: OOG vs IG Cargo

OOG (Out of Gauge) cargo incurs significantly higher transportation costs compared to IG (In Gauge) cargo due to its non-standard dimensions requiring specialized handling, permits, and often escort vehicles. IG cargo fits within standard container dimensions, enabling streamlined loading, stacking, and shipping, which reduces overall freight and insurance expenses. The complexity and regulatory compliance associated with OOG cargo lead to increased operational costs, delays, and potential surcharges, making it essential for logistics planning and budgeting.

Documentation and Compliance Requirements

OOG (Out of Gauge) shipments require extensive documentation including special permits, detailed dimensions, and route surveys to ensure compliance with transportation regulations, whereas IG (In Gauge) cargo follows standard documentation protocols such as bills of lading and packing lists. Compliance for OOG cargo involves adherence to legal restrictions on size, weight, and handling procedures enforced by transport authorities to prevent safety hazards and infrastructure damage. Your accuracy in preparing and submitting all necessary OOG compliance documents directly impacts the smooth approval and transit of oversized cargo shipments.

Safety Considerations in OOG and IG Transport

OOG (Out of Gauge) cargo requires specialized handling and transport equipment due to its oversized dimensions, posing increased safety risks such as load instability and route obstructions, necessitating rigorous risk assessments and compliance with strict regulatory standards. IG (In Gauge) cargo benefits from standardized container dimensions that facilitate safer stacking, easier securing, and smoother handling processes, significantly reducing the likelihood of accidents during transport. Effective safety considerations for OOG include route planning to avoid low bridges and narrow passages, use of escort vehicles, and enhanced securing methods, whereas IG transport emphasizes proper load distribution within standardized containers to maintain stability.

Choosing the Right Shipping Solution: OOG or IG

Choosing the right shipping solution depends on whether your cargo is Out of Gauge (OOG) or In Gauge (IG), as OOG cargo exceeds standard container dimensions and requires specialized handling, equipment, and route planning. IG cargo fits within standard container sizes, allowing for more straightforward loading, cost-effective shipping, and compatibility with most transportation networks. Assessing your shipment's dimensions and weight ensures you select the optimal method, minimizing delays and extra costs.

OOG (out of gauge) vs IG (in gauge) Infographic

libmatt.com

libmatt.com