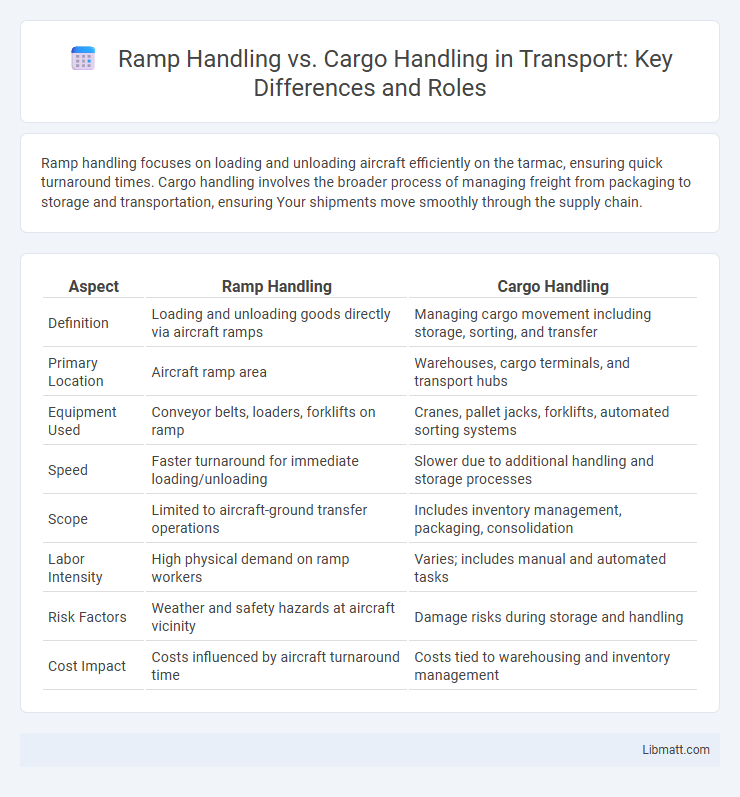

Ramp handling focuses on loading and unloading aircraft efficiently on the tarmac, ensuring quick turnaround times. Cargo handling involves the broader process of managing freight from packaging to storage and transportation, ensuring Your shipments move smoothly through the supply chain.

Table of Comparison

| Aspect | Ramp Handling | Cargo Handling |

|---|---|---|

| Definition | Loading and unloading goods directly via aircraft ramps | Managing cargo movement including storage, sorting, and transfer |

| Primary Location | Aircraft ramp area | Warehouses, cargo terminals, and transport hubs |

| Equipment Used | Conveyor belts, loaders, forklifts on ramp | Cranes, pallet jacks, forklifts, automated sorting systems |

| Speed | Faster turnaround for immediate loading/unloading | Slower due to additional handling and storage processes |

| Scope | Limited to aircraft-ground transfer operations | Includes inventory management, packaging, consolidation |

| Labor Intensity | High physical demand on ramp workers | Varies; includes manual and automated tasks |

| Risk Factors | Weather and safety hazards at aircraft vicinity | Damage risks during storage and handling |

| Cost Impact | Costs influenced by aircraft turnaround time | Costs tied to warehousing and inventory management |

Overview of Ramp Handling and Cargo Handling

Ramp handling primarily involves the management of aircraft ground services such as loading and unloading baggage, aircraft marshaling, and refueling, ensuring efficient turnaround times. Cargo handling focuses on the processing, storage, and transportation of freight, including sorting, documentation, and secure loading of goods onto aircraft. Both functions are critical components of airport ground operations, optimizing airline efficiency and safety through specialized equipment and trained personnel.

Key Responsibilities in Ramp Handling

Ramp handling involves the efficient loading and unloading of aircraft, including baggage transfer, aircraft marshaling, and ground support equipment operation. Key responsibilities include ensuring timely turnaround by managing cargo positioning, passenger boarding bridges, aircraft refueling coordination, and safety compliance on the ramp area. Effective ramp handling minimizes aircraft downtime and enhances overall airport operational efficiency.

Primary Functions of Cargo Handling

Cargo handling primarily involves the loading, unloading, storage, and movement of goods within warehouses, ships, trucks, or containers, ensuring efficient and safe transfer of products. It includes inventory management, packaging, and documentation to maintain accuracy and traceability throughout the supply chain. Unlike ramp handling, which focuses on aircraft-related tasks like baggage and fueling, cargo handling optimizes the overall logistics and distribution process of freight.

Equipment Used in Ramp and Cargo Operations

Ramp handling employs specialized equipment such as aircraft tugs, belt loaders, and ground power units to facilitate aircraft movement, baggage loading, and maintenance support on the ramp. Cargo handling relies heavily on forklifts, container loaders, pallet jacks, and conveyor systems to efficiently load, unload, and transport freight within cargo terminals. Both operations integrate high-tech tracking and scanning devices to ensure accuracy, safety, and timely processing of goods and luggage.

Safety Protocols: Ramp vs Cargo Handling

Safety protocols in ramp handling emphasize vehicle and aircraft movement coordination, ensuring ground support equipment operates without interfering with aircraft operations to prevent accidents. Cargo handling safety focuses on proper lifting techniques, secure packaging, and load distribution to protect workers and prevent damage to goods during transit. Understanding these distinct safety measures helps you maintain compliance and reduce risks in both ramp and cargo operations.

Staff Training and Qualifications Required

Ramp handling requires staff to be trained in aircraft marshaling, baggage loading, and ground support equipment operation, emphasizing safety and efficiency around active aircraft. Cargo handling staff must possess specialized knowledge in cargo securing, hazardous material regulations, and documentation processes to ensure compliance and accurate shipment management. Both roles demand certifications and ongoing training to meet aviation industry standards and maintain operational safety.

Common Challenges in Ramp and Cargo Handling

Ramp handling and cargo handling face common challenges such as time constraints, ensuring safety compliance, and managing environmental factors like weather conditions. Both processes require precise coordination to prevent damage and delays, with staff needing specialized training to handle diverse cargo types and varying aircraft configurations. Efficient communication and use of technology are critical to overcoming obstacles related to equipment malfunctions and logistical bottlenecks.

Efficiency and Time Management Comparison

Ramp handling streamlines aircraft turnaround by focusing on quick ground services such as fueling, baggage loading, and aircraft towing, significantly reducing idle time on the tarmac. Cargo handling prioritizes the sorting, storage, and secure loading of freight, emphasizing accuracy and organization to minimize delays in shipment processing. Ramp handling generally offers faster turnaround times due to its direct impact on flight schedules, while cargo handling's efficiency is measured by its ability to process large volumes swiftly without compromising shipment integrity.

Impact on Airline Operations and Turnaround Times

Ramp handling directly influences airline operations by ensuring timely aircraft servicing, including refueling, baggage loading, and pushback, which minimizes delays and supports efficient turnaround times. Cargo handling, while focused on accurate and secure loading and unloading of freight, affects overall scheduling as any bottlenecks can extend ground time and impact flight departures. Efficient coordination between ramp and cargo handling teams is essential to optimize turnaround performance and maintain airline punctuality.

Technological Innovations in Ramp and Cargo Handling

Technological innovations in ramp handling include automated baggage loaders, real-time tracking systems, and electric ground support equipment that enhance efficiency and safety during aircraft turnaround. Cargo handling advancements feature AI-powered sorting systems, blockchain for secure shipment tracking, and robotics for load optimization, significantly reducing processing time and errors. You can benefit from these innovations through improved operational speed, accuracy, and reduced environmental impact in both ramp and cargo operations.

ramp handling vs cargo handling Infographic

libmatt.com

libmatt.com