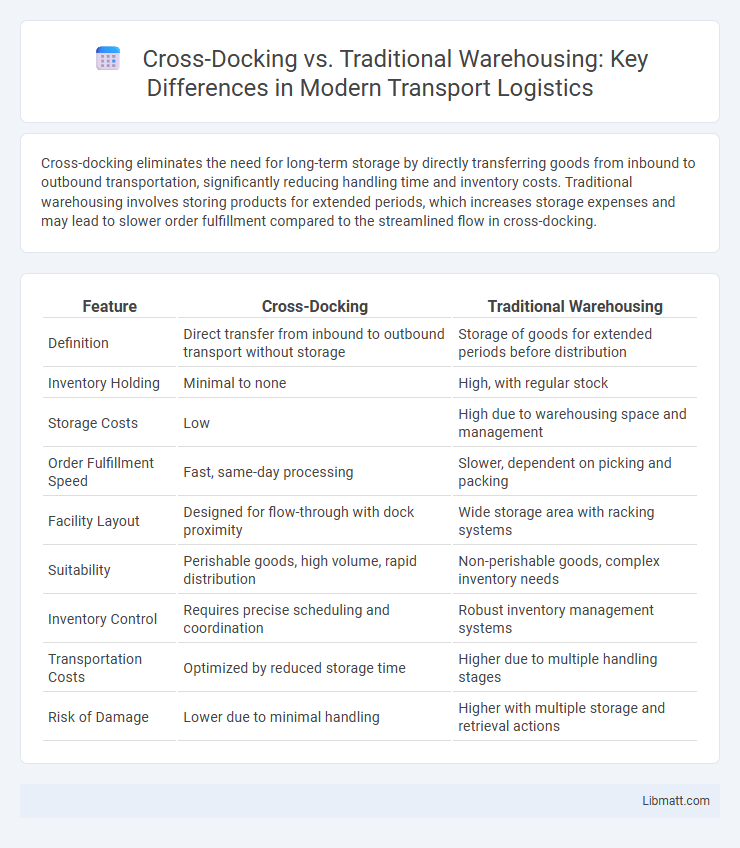

Cross-docking eliminates the need for long-term storage by directly transferring goods from inbound to outbound transportation, significantly reducing handling time and inventory costs. Traditional warehousing involves storing products for extended periods, which increases storage expenses and may lead to slower order fulfillment compared to the streamlined flow in cross-docking.

Table of Comparison

| Feature | Cross-Docking | Traditional Warehousing |

|---|---|---|

| Definition | Direct transfer from inbound to outbound transport without storage | Storage of goods for extended periods before distribution |

| Inventory Holding | Minimal to none | High, with regular stock |

| Storage Costs | Low | High due to warehousing space and management |

| Order Fulfillment Speed | Fast, same-day processing | Slower, dependent on picking and packing |

| Facility Layout | Designed for flow-through with dock proximity | Wide storage area with racking systems |

| Suitability | Perishable goods, high volume, rapid distribution | Non-perishable goods, complex inventory needs |

| Inventory Control | Requires precise scheduling and coordination | Robust inventory management systems |

| Transportation Costs | Optimized by reduced storage time | Higher due to multiple handling stages |

| Risk of Damage | Lower due to minimal handling | Higher with multiple storage and retrieval actions |

Introduction to Cross-Docking and Traditional Warehousing

Cross-docking streamlines supply chains by transferring goods directly from inbound to outbound transportation with minimal or no storage, reducing inventory holding costs and cycle times. Traditional warehousing involves storing products for extended periods, allowing for inventory accumulation, order fulfillment, and demand buffering. Cross-docking optimizes efficiency and responsiveness, while traditional warehousing supports inventory management and demand variability.

Key Differences Between Cross-Docking and Traditional Warehousing

Cross-docking minimizes inventory storage by directly transferring goods from inbound to outbound transportation, significantly reducing handling time and storage costs compared to traditional warehousing that relies on prolonged inventory holding. Traditional warehousing focuses on stockpiling products for future demand, enabling bulk purchasing and safety stock maintenance, while cross-docking emphasizes rapid throughput and real-time order fulfillment. Operational complexity in cross-docking requires precise coordination and advanced logistics technology, whereas traditional warehouses employ systematic inventory management with extensive storage space.

How Cross-Docking Works

Cross-docking streamlines supply chain efficiency by transferring products directly from inbound to outbound transportation with minimal to no storage time. This method reduces warehousing costs and speeds up order fulfillment by eliminating the need for long-term inventory holding. Your business benefits from faster delivery times and decreased handling, making cross-docking ideal for perishable goods and high-demand products.

How Traditional Warehousing Operates

Traditional warehousing involves storing goods in a facility for extended periods, where inventory is received, stored, and managed until orders are fulfilled. This method requires substantial space, labor for handling, and complex inventory management systems to track stock levels and movement. The process ensures product availability but often leads to higher storage costs and longer lead times compared to cross-docking.

Benefits of Cross-Docking

Cross-docking reduces inventory holding costs by minimizing storage time, enabling faster order fulfillment and improved supply chain efficiency. This method streamlines product flow from suppliers to customers, cutting down handling and transportation expenses significantly. By leveraging cross-docking, Your operations benefit from enhanced delivery speed, reduced warehouse space requirements, and lower risk of stock obsolescence.

Advantages of Traditional Warehousing

Traditional warehousing offers significant advantages including enhanced inventory control, allowing businesses to store large quantities of products securely and manage stock levels efficiently. It provides the flexibility to handle seasonal fluctuations and bulk storage, supporting order fulfillment and reducing stockouts. Additionally, traditional warehousing facilitates value-added services such as packaging, labeling, and quality inspection, improving overall supply chain responsiveness.

When to Use Cross-Docking vs Traditional Warehousing

Cross-docking is ideal for businesses needing rapid inventory turnover and reduced storage costs, especially with perishable goods or high-demand items requiring minimal handling. Traditional warehousing suits companies requiring long-term storage, complex inventory management, and order customization, allowing greater control over stock levels. Your choice depends on factors like product type, delivery speed, and inventory complexity to optimize supply chain efficiency.

Cost Comparison: Cross-Docking vs Traditional Warehousing

Cross-docking significantly reduces inventory holding costs by minimizing storage time and handling fees, resulting in lower operational expenses compared to traditional warehousing. Traditional warehousing incurs higher costs due to prolonged storage, increased labor for inventory management, and larger space requirements. Companies leveraging cross-docking can achieve faster turnover and reduced overhead, ultimately enhancing cost efficiency in supply chain management.

Challenges and Limitations of Each Method

Cross-docking faces challenges such as high dependency on precise timing and coordination, leading to risks of delays and limited buffer storage options. Traditional warehousing encounters limitations like increased inventory holding costs, longer order fulfillment cycles, and potential inefficiencies in space utilization. Your choice between methods should consider these factors to optimize supply chain effectiveness.

Future Trends in Warehousing and Distribution

Future trends in warehousing and distribution emphasize the rise of cross-docking due to its ability to reduce inventory holding costs and accelerate order fulfillment. Advanced technologies such as AI-driven automation, real-time data analytics, and IoT integration are enhancing cross-docking efficiency by optimizing shipment coordination and improving supply chain visibility. Traditional warehousing still plays a crucial role in inventory management but is increasingly integrated with dynamic cross-docking systems to meet evolving demands for speed and flexibility in logistics operations.

cross-docking vs traditional warehousing Infographic

libmatt.com

libmatt.com