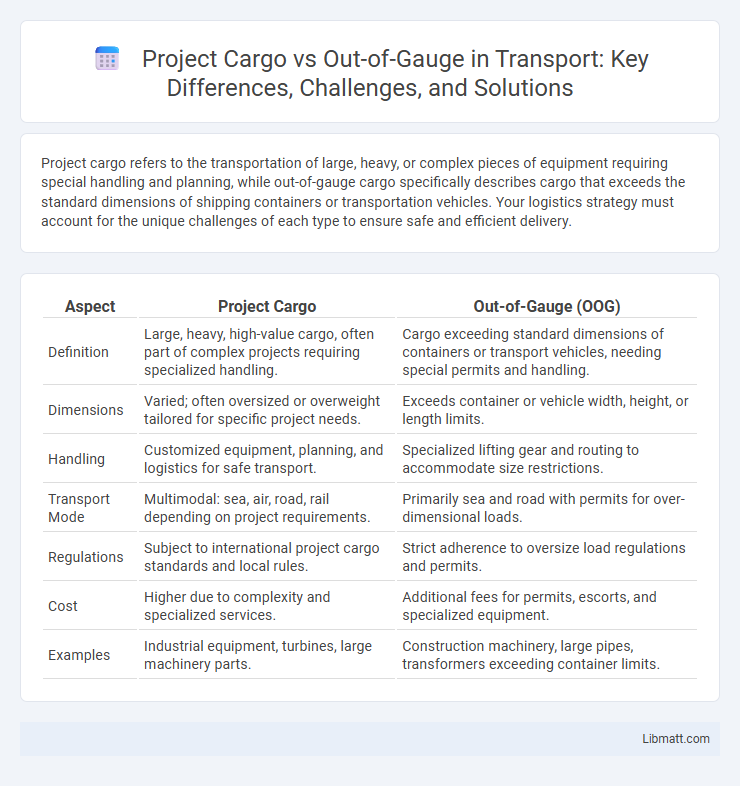

Project cargo refers to the transportation of large, heavy, or complex pieces of equipment requiring special handling and planning, while out-of-gauge cargo specifically describes cargo that exceeds the standard dimensions of shipping containers or transportation vehicles. Your logistics strategy must account for the unique challenges of each type to ensure safe and efficient delivery.

Table of Comparison

| Aspect | Project Cargo | Out-of-Gauge (OOG) |

|---|---|---|

| Definition | Large, heavy, high-value cargo, often part of complex projects requiring specialized handling. | Cargo exceeding standard dimensions of containers or transport vehicles, needing special permits and handling. |

| Dimensions | Varied; often oversized or overweight tailored for specific project needs. | Exceeds container or vehicle width, height, or length limits. |

| Handling | Customized equipment, planning, and logistics for safe transport. | Specialized lifting gear and routing to accommodate size restrictions. |

| Transport Mode | Multimodal: sea, air, road, rail depending on project requirements. | Primarily sea and road with permits for over-dimensional loads. |

| Regulations | Subject to international project cargo standards and local rules. | Strict adherence to oversize load regulations and permits. |

| Cost | Higher due to complexity and specialized services. | Additional fees for permits, escorts, and specialized equipment. |

| Examples | Industrial equipment, turbines, large machinery parts. | Construction machinery, large pipes, transformers exceeding container limits. |

Understanding Project Cargo: Definition and Scope

Project cargo refers to the transportation of large, heavy, high-value, or critical pieces of equipment essential for complex industrial projects, often requiring specialized handling and logistics solutions. It encompasses oversized and overweight cargo that cannot be disassembled, distinguishing it from standard freight by its unique challenges in planning, packaging, and route assessment. Out-of-gauge cargo, a subset of project cargo, specifically describes shipments exceeding the dimensions of standard containers or transport vehicles, necessitating custom transport arrangements to ensure safety and compliance.

What is Out-of-Gauge (OOG) Cargo?

Out-of-Gauge (OOG) cargo refers to shipments that exceed the standard dimensions and weight limits of regular shipping containers, requiring special handling and transportation methods. This type of cargo often involves oversized or irregularly shaped items that cannot be accommodated by conventional containers, necessitating custom solutions such as flat racks or multi-modal transport. Understanding OOG cargo is essential for optimizing logistics and ensuring your shipments are safely and efficiently managed.

Key Differences Between Project Cargo and OOG Cargo

Project cargo involves transporting large, heavy, or complex equipment often requiring specialized handling and planning, whereas out-of-gauge (OOG) cargo specifically refers to shipments exceeding standard container dimensions. Project cargo focuses on precision logistics for oversized or heavy items, while OOG cargo primarily concerns the physical dimensions that prevent standard container use. Your choice between project cargo and OOG transport depends on whether the shipment's complexity or size governs the logistics requirements.

Types of Goods Handled in Project Cargo vs. OOG

Project cargo typically involves transporting large, heavy, or complex equipment such as machinery, industrial components, and construction materials, often requiring specialized handling and logistics. Out-of-gauge (OOG) cargo refers to goods that exceed the standard dimensions or weight limits of shipping containers, including oversized vehicles, large pipes, and wind turbine blades. Your choice between project cargo and OOG handling depends on the specific requirements of the cargo's size, shape, and transportation constraints.

Transportation Methods for Project and OOG Cargo

Transportation methods for project cargo and out-of-gauge (OOG) cargo often involve specialized equipment such as flat racks, extendable trailers, and heavy-duty lowboys designed to handle oversized and heavy loads. Multimodal transport combining sea, rail, and road offers flexibility for navigating complex routes while ensuring cargo integrity. Advanced planning incorporates route surveys, load calculations, and permits to accommodate dimensions exceeding standard shipping container sizes.

Packaging and Handling Requirements

Project cargo typically involves customized packaging solutions designed to secure oversized and heavy equipment during transport, requiring reinforced crates and specialized supports. Out-of-gauge cargo demands packaging that accommodates dimensions exceeding standard container limits, often utilizing flat racks or open-top containers to ensure safe handling. Proper handling for both categories includes the use of heavy-lift cranes, specialized rigging, and adherence to strict weight distribution protocols to prevent damage and maintain cargo integrity.

Documentation and Compliance Considerations

Project cargo shipments require extensive documentation including detailed route surveys, weight certifications, and engineering plans to ensure compliance with transport regulations and safety standards. Out-of-gauge cargo demands specialized permits and precise dimensional declarations to meet legal and customs requirements due to its non-standard size exceeding container limits. Both types of cargo necessitate rigorous adherence to international and local regulations to avoid delays and penalties during transit.

Challenges in Shipping Project Cargo vs. OOG

Shipping project cargo involves handling oversized, heavy, and complex equipment that demands specialized planning, route surveys, and lifting techniques to avoid damage and ensure safety. Out-of-gauge (OOG) shipments, characterized by cargo exceeding standard container dimensions, pose challenges such as securing permits, selecting appropriate transport modes, and navigating infrastructure constraints like low bridges or narrow roads. Your logistics strategy must address these unique challenges to optimize transport efficiency and mitigate risks in both project cargo and OOG shipments.

Cost Factors and Budgeting for Both Cargo Types

Project cargo involves large, heavy, or complex shipments requiring specialized equipment, leading to higher transportation, handling, and insurance costs compared to standard freight. Out-of-gauge cargo, defined by its dimensions exceeding standard container sizes, demands customized packaging and route planning, often increasing logistics expenses due to permits and escorts. Understanding these cost factors helps you budget accurately, ensuring adequate allocation for permits, specialized handling, and potential route modifications.

Choosing the Right Logistics Partner for Specialized Cargo

Selecting the right logistics partner for project cargo and out-of-gauge shipments ensures the safe handling, specialized equipment use, and compliance with regulatory requirements essential for oversized or heavy loads. Expertise in route planning, customs clearance, and risk management is crucial to prevent delays and damages during transport. You benefit from streamlined operations and reduced costs when working with a provider experienced in managing complex logistics challenges unique to project and out-of-gauge cargo.

project cargo vs out-of-gauge Infographic

libmatt.com

libmatt.com