Double stack containers maximize shipping efficiency by allowing two layers of containers to be stacked, effectively doubling cargo capacity on trains or ships within the same footprint, whereas single stack containers are limited to one layer, reducing space utilization. Choosing double stack containers can lower transportation costs and improve your supply chain's productivity by enabling higher volume shipment with less infrastructure.

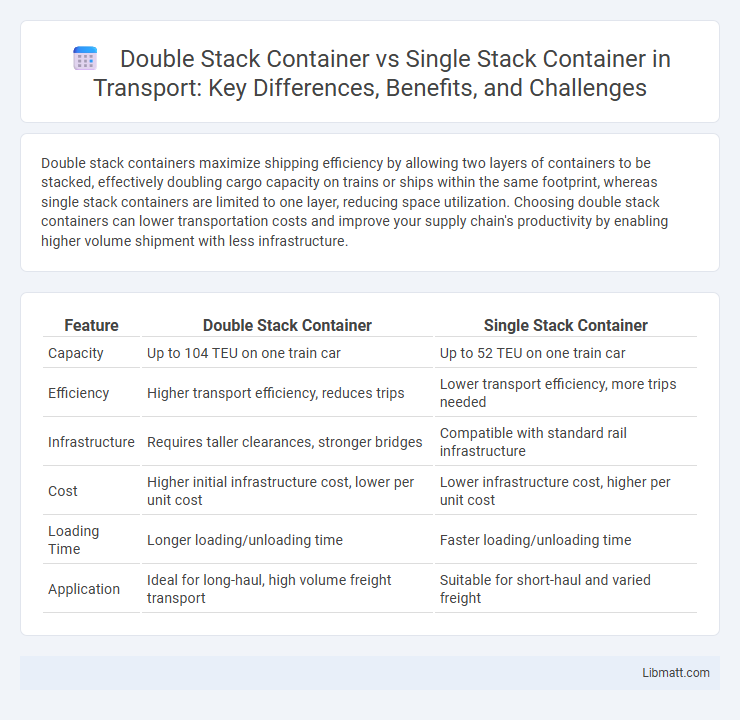

Table of Comparison

| Feature | Double Stack Container | Single Stack Container |

|---|---|---|

| Capacity | Up to 104 TEU on one train car | Up to 52 TEU on one train car |

| Efficiency | Higher transport efficiency, reduces trips | Lower transport efficiency, more trips needed |

| Infrastructure | Requires taller clearances, stronger bridges | Compatible with standard rail infrastructure |

| Cost | Higher initial infrastructure cost, lower per unit cost | Lower infrastructure cost, higher per unit cost |

| Loading Time | Longer loading/unloading time | Faster loading/unloading time |

| Application | Ideal for long-haul, high volume freight transport | Suitable for short-haul and varied freight |

Introduction to Double Stack vs Single Stack Containers

Double stack containers optimize space utilization by stacking two containers vertically on a single railcar, effectively doubling freight capacity compared to single stack containers, which are placed one per railcar. This method reduces transportation costs and increases efficiency in intermodal shipping, making it ideal for long-haul routes with appropriate infrastructure clearance. Your choice between double stack and single stack containers depends on factors like route restrictions, cargo type, and terminal facilities.

Key Differences Between Double and Single Stack Containers

Double stack containers maximize railcar efficiency by allowing two standard containers to be stacked vertically, doubling cargo capacity compared to single stack containers, which only carry one container per railcar. Single stack containers offer simpler loading and unloading processes, reducing handling time and minimizing risk of container damage. Structural requirements and railcar design differ significantly, with double stack trains requiring specialized railcars and clearances to accommodate the increased height.

Space Efficiency and Capacity Comparisons

Double stack containers maximize space efficiency by allowing two containers to be stacked vertically, effectively doubling the carrying capacity on the same railcar or trailer footprint compared to single stack containers. This configuration significantly enhances cargo volume per trip, optimizing transport logistics and reducing costs. However, double stack systems require specialized infrastructure like taller railcars and clearances, limiting their use in certain regions.

Impact on Transportation Costs

Double stack containers significantly reduce transportation costs by maximizing railcar and ship capacity, allowing more containers to be moved per trip compared to single stack containers. This efficient use of space leads to lower fuel consumption and decreased per-unit shipping expenses. Your logistics operations benefit from higher volume shipments at reduced costs, improving overall supply chain efficiency.

Infrastructure Requirements and Compatibility

Double stack container systems require specialized railcars and higher clearance infrastructure, including elevated bridges, taller tunnels, and reinforced tracks, to safely accommodate the stacked containers. In contrast, single stack container operations demand less stringent clearance and structural modifications, making them compatible with more existing rail and road networks. Infrastructure investments for double stack setups can be substantial but dramatically increase cargo capacity and efficiency on key transportation corridors.

Loading and Unloading Processes

Double stack containers significantly improve loading and unloading efficiency by allowing two containers to be stacked vertically on railcars or specialized trailers, maximizing space utilization and reducing the number of trips required. This method requires specialized equipment and careful planning to ensure stability and safety during handling, while single stack containers offer simpler logistics but demand more time and resources for the same volume. Optimizing your supply chain with double stacking can lead to faster turnaround times and lower transportation costs.

Safety Considerations and Risk Management

Double stack containers improve operational efficiency but require enhanced safety measures due to increased load height and weight, demanding stronger securing systems and rigorous inspection protocols. Single stack containers reduce the risk of toppling and facilitate easier handling, lowering the likelihood of accidents and structural failures during transport. Effective risk management in double stacking involves thorough training, precise weight distribution, and continuous monitoring to prevent instability and ensure compliance with regulatory standards.

Environmental Impact and Sustainability

Double stack containers significantly reduce transportation emissions by maximizing cargo volume per trip, thereby lowering fuel consumption and greenhouse gas output compared to single stack containers. This increased efficiency supports sustainable logistics by minimizing the carbon footprint associated with shipping operations. Your choice of double stack container usage promotes environmentally responsible supply chain practices through enhanced resource optimization.

Industry Applications and Use Cases

Double stack containers are extensively used in the rail and shipping industries for maximizing cargo capacity and reducing transportation costs, especially for bulk goods and intermodal freight. Single stack containers remain prevalent in industries requiring quick and frequent loading and unloading, such as retail and perishables, where accessibility and speed are prioritized over volume. Both container types support global supply chains, with double stack enhancing long-haul efficiency while single stack offers flexibility for short-haul and urban delivery routes.

Choosing the Right Container Solution

Selecting between double stack and single stack containers depends on your shipping volume, port infrastructure, and cost-efficiency priorities. Double stack containers maximize cargo capacity by allowing two containers to be stacked on railcars or trucks, significantly reducing transportation costs per unit. Your optimal container solution balances operational needs, route limitations, and handling equipment compatibility to enhance logistical efficiency.

double stack container vs single stack container Infographic

libmatt.com

libmatt.com