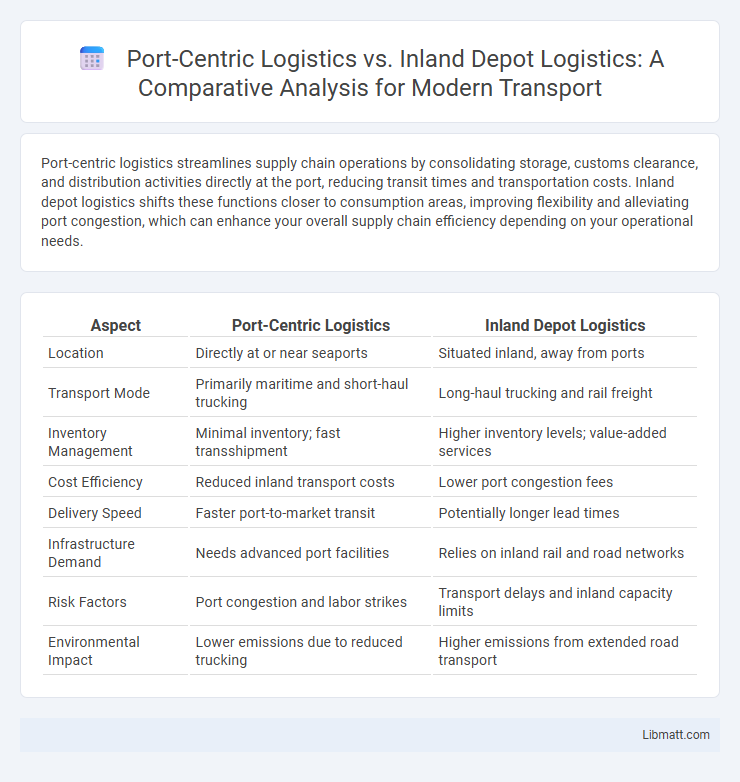

Port-centric logistics streamlines supply chain operations by consolidating storage, customs clearance, and distribution activities directly at the port, reducing transit times and transportation costs. Inland depot logistics shifts these functions closer to consumption areas, improving flexibility and alleviating port congestion, which can enhance your overall supply chain efficiency depending on your operational needs.

Table of Comparison

| Aspect | Port-Centric Logistics | Inland Depot Logistics |

|---|---|---|

| Location | Directly at or near seaports | Situated inland, away from ports |

| Transport Mode | Primarily maritime and short-haul trucking | Long-haul trucking and rail freight |

| Inventory Management | Minimal inventory; fast transshipment | Higher inventory levels; value-added services |

| Cost Efficiency | Reduced inland transport costs | Lower port congestion fees |

| Delivery Speed | Faster port-to-market transit | Potentially longer lead times |

| Infrastructure Demand | Needs advanced port facilities | Relies on inland rail and road networks |

| Risk Factors | Port congestion and labor strikes | Transport delays and inland capacity limits |

| Environmental Impact | Lower emissions due to reduced trucking | Higher emissions from extended road transport |

Introduction to Port-Centric and Inland Depot Logistics

Port-centric logistics centralizes cargo handling and distribution directly at or near the seaport, reducing inland transportation costs and improving supply chain efficiency. Inland depot logistics involves transferring goods from ports to strategically located inland facilities, facilitating decongestion at ports and enhancing regional distribution networks. Both models optimize different stages of freight movement, with port-centric focusing on immediate port area operations and inland depots enabling extended reach into the hinterland.

Defining Port-Centric Logistics

Port-centric logistics centers on the consolidation and distribution of goods directly at or near seaports, streamlining supply chains by reducing inland transportation costs and transit times. Unlike inland depot logistics, which involves moving cargo to remote inland facilities for sorting and storage, port-centric logistics integrates warehousing, customs, and transportation services within the port area itself. This approach enhances supply chain efficiency, allowing you to optimize inventory management and accelerate delivery in global trade networks.

Understanding Inland Depot Logistics

Inland depot logistics involves the strategic use of facilities located away from port terminals to handle cargo consolidation, customs clearance, and storage, reducing congestion at ports and improving supply chain efficiency. These inland depots serve as critical nodes for multimodal transport, linking sea, rail, and road networks to streamline cargo movement closer to consumption centers. Understanding inland depot logistics helps you optimize inventory management, lower transportation costs, and enhance overall responsiveness in global trade operations.

Key Differences Between Port-Centric and Inland Depot Logistics

Port-centric logistics centralizes freight handling and distribution at or near the port, reducing transportation costs and transit times with direct access to shipping vessels. Inland depot logistics involves moving containers to inland locations away from the port, enabling congestion relief at the port and providing regional distribution hubs for last-mile delivery. The key differences lie in the location of cargo handling, impact on transportation costs, and the role of supply chain connectivity between maritime ports and inland distribution centers.

Advantages of Port-Centric Logistics

Port-centric logistics centralizes cargo handling and distribution directly at the port, significantly reducing transportation costs and transit times. This approach enhances supply chain efficiency by minimizing inland trucking, lowering carbon emissions, and improving inventory visibility and control. Your business benefits from faster turnaround, reduced congestion in urban areas, and streamlined customs processing.

Benefits of Inland Depot Logistics

Inland depot logistics offers significant benefits, including reduced congestion and lower handling costs at busy seaports by shifting cargo processing inland. These depots enhance supply chain efficiency by providing more flexible storage, customs clearance, and value-added services closer to your final destination. Utilizing inland depots can lead to faster turnaround times, improved cargo security, and decreased transportation costs compared to traditional port-centric logistics.

Cost Considerations and Efficiency

Port-centric logistics often reduce overall transportation costs by consolidating cargo handling directly at the port, minimizing inland freight expenses and transit times. Inland depot logistics can offer lower storage costs and flexible inventory management but may increase last-mile transportation expenses and handling complexity. Your choice depends on balancing direct port efficiency with inland depot flexibility to optimize supply chain cost and speed.

Environmental Impact Comparison

Port-centric logistics reduces carbon emissions by minimizing cargo movement between ports and inland depots, leading to fewer truck trips and lower fuel consumption. Inland depot logistics often involve extended transportation routes, increasing greenhouse gas emissions and environmental pollution. Optimizing Your supply chain with port-centric solutions enhances sustainability by leveraging proximity to maritime terminals for efficient cargo handling and reduced ecological footprint.

Choosing the Right Logistics Model

Selecting the right logistics model depends on your supply chain priorities, whether emphasizing port-centric logistics for faster turnaround and reduced transportation costs or inland depot logistics for improved inventory management and regional distribution efficiency. Port-centric logistics centralize operations near the port, minimizing lead times and optimizing container handling, while inland depots offer flexibility by moving storage closer to demand centers. Evaluating factors like shipment volume, transit time, and cost implications ensures your logistics strategy aligns with operational goals.

Future Trends in Logistics Strategies

Future trends in logistics strategies emphasize the growing integration of port-centric logistics, which streamlines cargo handling by consolidating shipment processes directly at ports, reducing transit times and costs. Inland depot logistics are evolving with advanced intermodal facilities and digital platforms that enhance cargo tracking and distribution efficiency inland, supporting just-in-time delivery systems. Your supply chain can benefit from hybrid models that leverage both port-centric and inland depot logistics to optimize flexibility and responsiveness in global trade networks.

port-centric logistics vs inland depot logistics Infographic

libmatt.com

libmatt.com