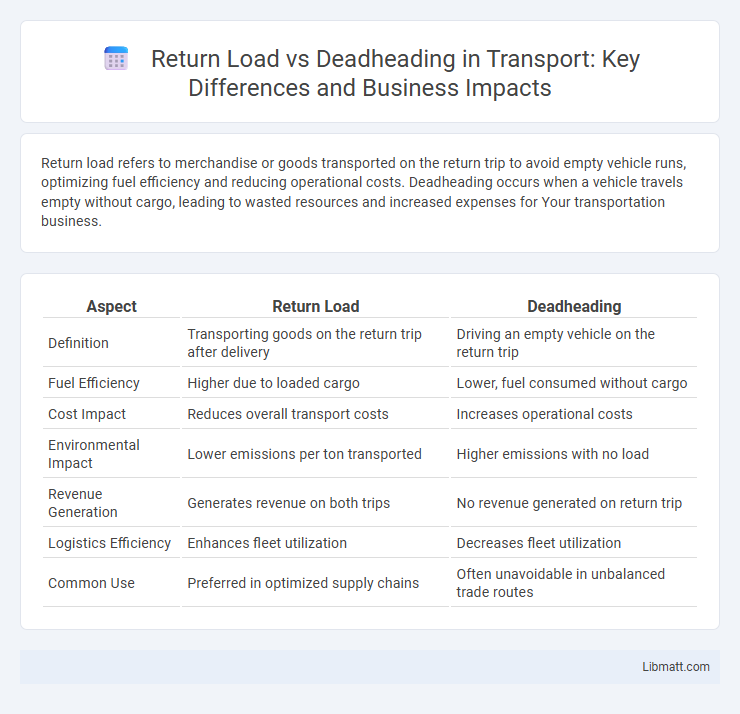

Return load refers to merchandise or goods transported on the return trip to avoid empty vehicle runs, optimizing fuel efficiency and reducing operational costs. Deadheading occurs when a vehicle travels empty without cargo, leading to wasted resources and increased expenses for Your transportation business.

Table of Comparison

| Aspect | Return Load | Deadheading |

|---|---|---|

| Definition | Transporting goods on the return trip after delivery | Driving an empty vehicle on the return trip |

| Fuel Efficiency | Higher due to loaded cargo | Lower, fuel consumed without cargo |

| Cost Impact | Reduces overall transport costs | Increases operational costs |

| Environmental Impact | Lower emissions per ton transported | Higher emissions with no load |

| Revenue Generation | Generates revenue on both trips | No revenue generated on return trip |

| Logistics Efficiency | Enhances fleet utilization | Decreases fleet utilization |

| Common Use | Preferred in optimized supply chains | Often unavoidable in unbalanced trade routes |

Understanding Return Load and Deadheading

Return load refers to the cargo transported back to the original location after completing a delivery, optimizing vehicle utilization and reducing empty miles. Deadheading occurs when a truck or vehicle travels empty without any cargo, incurring costs without generating revenue, impacting your overall logistics efficiency. Properly managing return loads minimizes deadheading, improving profitability and environmental sustainability in freight operations.

Key Differences Between Return Load and Deadheading

Return load involves transporting cargo on the return trip of a vehicle after making a delivery, maximizing efficiency and reducing operational costs. Deadheading occurs when a vehicle travels empty without any cargo, leading to wasted fuel and increased expenses. Understanding these differences helps you optimize logistics and improve overall fleet productivity.

The Impact of Return Load on Operational Efficiency

Return load significantly enhances operational efficiency by maximizing truck utilization and reducing empty miles. Unlike deadheading, where trucks travel without cargo, carrying a return load lowers fuel consumption and operational costs while improving profit margins. Efficient management of return loads contributes to smoother supply chain flows and increased sustainability in logistics operations.

Costs Associated with Deadheading in Transport

Deadheading in transport generates significant costs due to unused fuel consumption, increased labor expenses, and accelerated vehicle wear and tear during empty return trips. These inefficiencies reduce overall fleet productivity and increase operational expenditures, negatively impacting your logistics budget. Optimizing routes to minimize return loads can effectively lower deadheading costs and improve transport profitability.

Environmental Implications: Return Load vs Deadheading

Return load reduces environmental impact by optimizing vehicle capacity and minimizing empty miles, thereby lowering fuel consumption and greenhouse gas emissions. Deadheading, the practice of driving empty trucks or trailers, leads to increased carbon footprint and inefficient resource use in freight transportation. Implementing return load strategies supports sustainable logistics by enhancing operational efficiency and reducing the carbon intensity of supply chains.

Strategies to Reduce Deadheading Miles

Implementing route optimization software significantly reduces deadheading miles by calculating the most efficient paths for return loads. Utilizing freight matching platforms connects carriers with available loads near the delivery point, maximizing vehicle utilization on return trips. Coordinating backhaul agreements with consistent shippers ensures steady return cargo, minimizing empty miles and enhancing overall operational efficiency.

Leveraging Technology for Return Load Optimization

Leveraging technology for return load optimization significantly reduces deadheading, which is the empty miles traveled without cargo. Advanced route planning software and load-matching platforms enable you to identify profitable return loads, increasing fleet efficiency and cutting transportation costs. Real-time data analytics enhance decision-making by predicting demand patterns and matching shipments to available capacity, minimizing wasteful empty runs.

Real-World Case Studies: Successful Return Load Management

Return load management significantly reduces transportation costs and improves fleet utilization by avoiding deadheading, which wastes fuel and time on empty runs. In a notable case study, a logistics company achieved a 25% reduction in operational costs by implementing real-time load matching technology, optimizing return loads, and minimizing deadhead miles. Your business can gain a competitive edge by leveraging data-driven strategies that align shipments with available return trips, enhancing efficiency and sustainability.

Challenges in Achieving High Return Load Ratios

Achieving high return load ratios faces significant challenges due to imbalanced freight flows and geographic disparities between origin and destination points. Deadheading, or moving trucks empty, leads to increased operational costs, wasted fuel, and reduced efficiency in logistics networks. You must optimize route planning and freight matching technology to minimize empty miles and improve load utilization.

Future Trends: Minimizing Deadheading in Logistics

Future trends in logistics emphasize advanced route optimization technologies and AI-driven demand forecasting to minimize deadheading, reducing empty return loads that waste fuel and increase operational costs. Electric and autonomous vehicles are being integrated to enhance efficiency while supporting sustainable practices, further curbing unnecessary mileage. You can expect logistics companies to adopt these innovations to streamline return loads, improve resource utilization, and lower environmental impact.

return load vs deadheading Infographic

libmatt.com

libmatt.com