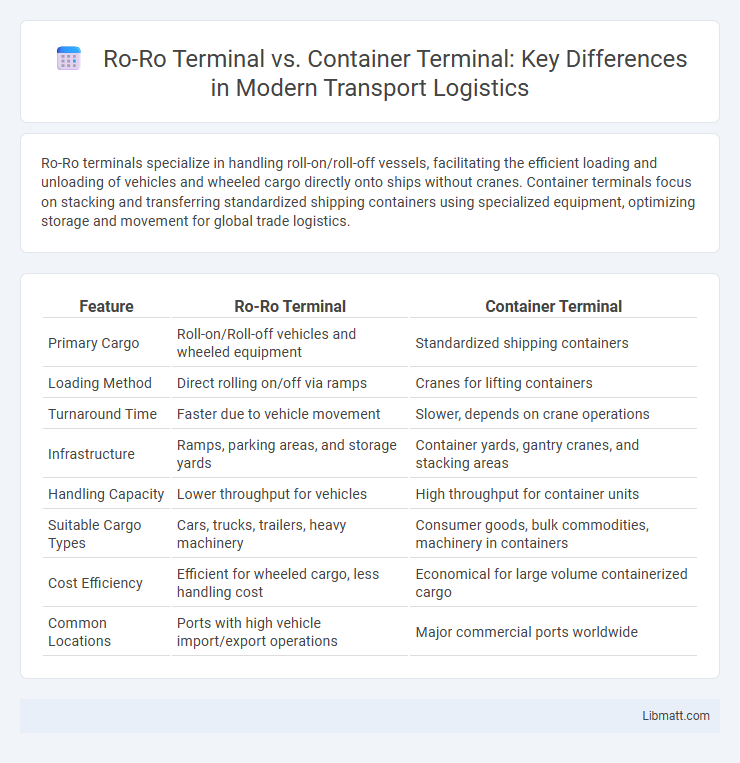

Ro-Ro terminals specialize in handling roll-on/roll-off vessels, facilitating the efficient loading and unloading of vehicles and wheeled cargo directly onto ships without cranes. Container terminals focus on stacking and transferring standardized shipping containers using specialized equipment, optimizing storage and movement for global trade logistics.

Table of Comparison

| Feature | Ro-Ro Terminal | Container Terminal |

|---|---|---|

| Primary Cargo | Roll-on/Roll-off vehicles and wheeled equipment | Standardized shipping containers |

| Loading Method | Direct rolling on/off via ramps | Cranes for lifting containers |

| Turnaround Time | Faster due to vehicle movement | Slower, depends on crane operations |

| Infrastructure | Ramps, parking areas, and storage yards | Container yards, gantry cranes, and stacking areas |

| Handling Capacity | Lower throughput for vehicles | High throughput for container units |

| Suitable Cargo Types | Cars, trucks, trailers, heavy machinery | Consumer goods, bulk commodities, machinery in containers |

| Cost Efficiency | Efficient for wheeled cargo, less handling cost | Economical for large volume containerized cargo |

| Common Locations | Ports with high vehicle import/export operations | Major commercial ports worldwide |

Introduction to Ro-Ro and Container Terminals

Ro-Ro terminals specialize in handling roll-on/roll-off cargo, primarily vehicles and wheeled equipment, using ramps for direct loading and unloading. Container terminals focus on the storage, transfer, and management of standardized shipping containers, employing cranes and automated systems for efficient handling. Both terminal types are essential in global logistics, facilitating the smooth flow of goods across maritime transport networks.

Key Differences Between Ro-Ro and Container Terminals

Ro-Ro terminals primarily handle wheeled cargo such as cars, trucks, and trailers that are driven on and off vessels, while container terminals specialize in the transfer and storage of standardized shipping containers using cranes and specialized equipment. Your logistics planning should account for Ro-Ro terminals' focus on fast, vehicle-based loading processes compared to the highly mechanized, container stacking operations at container terminals. Operational efficiency at Ro-Ro terminals depends on ramp design and vehicle flow management, whereas container terminals prioritize container yard organization, crane productivity, and intermodal connections.

Types of Cargo Handled

Ro-Ro terminals specialize in handling roll-on/roll-off cargo, primarily vehicles such as cars, trucks, trailers, and heavy machinery that can be driven on and off ships. Container terminals manage standardized intermodal containers used for a wide variety of goods, from consumer products to industrial equipment, enabling efficient stacking, storage, and transfer. The distinction in cargo types dictates the infrastructure and equipment requirements specific to each terminal's operations.

Terminal Design and Infrastructure

Ro-Ro terminals are designed with large, reinforced ramps and extensive parking areas to facilitate the efficient loading and unloading of wheeled cargo, such as cars, trucks, and trailers, whereas container terminals prioritize heavy-duty cranes, stacking yards, and modular berths to handle standardized shipping containers. Ro-Ro infrastructure demands spacious vehicle marshalling zones and robust linkspans to accommodate roll-on/roll-off vessels, while container terminals require advanced gantry cranes, automated guided vehicles (AGVs), and container yards for optimized container storage and movement. The structural layout of Ro-Ro terminals emphasizes streamlining vehicle movement, contrasting with container terminals where space optimization and multi-tier container stacking are critical for throughput efficiency.

Operational Processes and Workflow

Ro-Ro terminals specialize in the efficient handling of wheeled cargo such as cars, trucks, and trailers, using ramps for direct roll-on/roll-off operations that minimize loading and unloading times. Container terminals rely on cranes and specialized equipment to stack and transfer standardized containers, focusing on precise container placement and truck scheduling to optimize space and reduce dwell time. The workflow in Ro-Ro terminals emphasizes vehicle inspection and secure stowage, while container terminals prioritize container tracking systems and intermodal connectivity to streamline cargo movement.

Equipment and Technology Used

Ro-Ro terminals utilize specialized equipment such as ramps, linkspans, and automated guided vehicles (AGVs) designed to facilitate the efficient loading and unloading of wheeled cargo including cars, trucks, and trailers. Container terminals rely heavily on gantry cranes, straddle carriers, and automated stacking cranes (ASCs) equipped with advanced tracking systems for precise container handling and storage management. Your choice between Ro-Ro and container terminals should consider the specific technological capabilities and equipment tailored to the type of cargo being handled to optimize operational efficiency.

Advantages and Disadvantages

Ro-Ro terminals offer efficient handling of wheeled cargo, enabling faster loading and unloading processes compared to container terminals, which excel in standardized cargo transportation through containerization. Ro-Ro facilities reduce cargo damage risks due to direct vehicle movement but face limitations in cargo variety and volume handling, whereas container terminals provide greater versatility for diverse goods but involve longer processing times and higher infrastructure costs. Your choice depends on specific cargo needs, balancing rapid transit advantages of Ro-Ro with the scalability and security of container terminals.

Environmental Impact Considerations

Ro-Ro terminals typically produce lower emissions compared to container terminals due to fewer handling operations and less reliance on heavy machinery, reducing their environmental footprint. Container terminals often generate more air and noise pollution because of extensive crane use and container transport vehicles, increasing energy consumption and greenhouse gas emissions. You can minimize environmental impacts by selecting terminals with efficient logistics and adopting green technologies tailored to their operational characteristics.

Cost and Efficiency Comparison

Ro-Ro terminals typically offer lower handling costs and faster turnaround times for wheeled cargo due to minimal need for cargo re-stowing and specialized equipment, enhancing operational efficiency. Container terminals, while requiring higher investment in cranes and storage infrastructure, benefit from standardized container handling that supports large-scale, automated operations and efficient space utilization. Cost-efficiency depends on cargo type and volume; Ro-Ro excels with vehicles and rolling stock, whereas container terminals optimize containerized cargo throughput.

Future Trends in Terminal Development

Ro-Ro terminals are evolving with increased automation and enhanced digital tracking systems to handle rising vehicle volumes efficiently, while container terminals prioritize smart cranes and AI-driven logistics for faster container turnover. Both terminal types invest heavily in sustainability technologies, such as electrification and eco-friendly infrastructure, to meet global environmental regulations and reduce carbon footprints. Your operations can benefit from integrating IoT solutions and predictive analytics to optimize cargo flow and anticipate future demand shifts in terminal development.

Ro-Ro Terminal vs Container Terminal Infographic

libmatt.com

libmatt.com