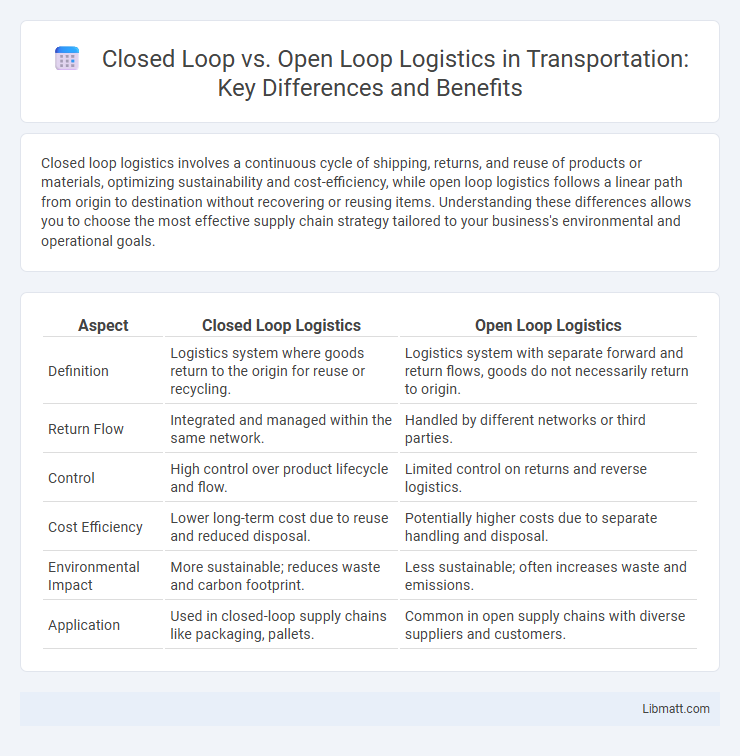

Closed loop logistics involves a continuous cycle of shipping, returns, and reuse of products or materials, optimizing sustainability and cost-efficiency, while open loop logistics follows a linear path from origin to destination without recovering or reusing items. Understanding these differences allows you to choose the most effective supply chain strategy tailored to your business's environmental and operational goals.

Table of Comparison

| Aspect | Closed Loop Logistics | Open Loop Logistics |

|---|---|---|

| Definition | Logistics system where goods return to the origin for reuse or recycling. | Logistics system with separate forward and return flows, goods do not necessarily return to origin. |

| Return Flow | Integrated and managed within the same network. | Handled by different networks or third parties. |

| Control | High control over product lifecycle and flow. | Limited control on returns and reverse logistics. |

| Cost Efficiency | Lower long-term cost due to reuse and reduced disposal. | Potentially higher costs due to separate handling and disposal. |

| Environmental Impact | More sustainable; reduces waste and carbon footprint. | Less sustainable; often increases waste and emissions. |

| Application | Used in closed-loop supply chains like packaging, pallets. | Common in open supply chains with diverse suppliers and customers. |

Introduction to Open Loop and Closed Loop Logistics

Open loop logistics involves a one-way flow of products from manufacturers to consumers without capturing or reusing returned items, emphasizing efficiency in distribution and delivery. Closed loop logistics integrates reverse logistics processes to recover, refurbish, or recycle products, minimizing waste and maximizing sustainability across the supply chain. Your business can enhance operational efficiency and environmental responsibility by understanding the distinctions and applications of both open loop and closed loop logistics systems.

Key Differences Between Open and Closed Loop Logistics

Open loop logistics involve products moving from manufacturer to consumer without return, focusing on one-way supply chain efficiency. Closed loop logistics emphasize product return, reuse, or recycling, integrating reverse logistics to minimize waste and maximize sustainability. Key differences include asset recovery processes, environmental impact, and cost structures associated with handling returned goods.

How Open Loop Logistics Operate

Open loop logistics operate by moving products from the manufacturer to the end consumer without the need for returning packaging or containers to the point of origin, enabling flexibility across multiple locations and participants. This system optimizes supply chains by leveraging third-party logistics providers who manage distribution, reverse logistics, and waste disposal independently. Efficient data tracking and inventory management software enhance transparency and reduce costs in open loop logistics operations.

Understanding the Closed Loop Logistics Model

Closed loop logistics integrates product return, refurbishment, and recycling processes to optimize resource efficiency and reduce environmental impact, contrasting with open loop logistics that primarily focuses on one-way distribution. Understanding the closed loop logistics model is essential for businesses aiming to enhance sustainability through continuous material flow and reduced waste. Your supply chain can benefit from lower costs and improved brand reputation by implementing closed loop strategies that align with circular economy principles.

Advantages of Closed Loop Logistics

Closed loop logistics enhances sustainability by maximizing resource reuse and reducing waste through efficient product returns and recycling processes. This system improves cost savings by lowering raw material expenses and minimizing disposal fees, while increasing supply chain transparency and control. Your business benefits from stronger customer loyalty and regulatory compliance by implementing closed loop logistics for more responsible environmental practices.

Benefits and Limitations of Open Loop Logistics

Open loop logistics offers the benefit of greater scalability and flexibility, allowing supply chains to operate across diverse, geographically dispersed networks without the constraints of product return flows. This system enhances product availability and can reduce inventory holding costs by leveraging multiple distribution points, but it often lacks the sustainability advantages present in closed loop logistics due to limited reuse or recycling opportunities. Your business may face challenges such as increased waste and environmental impact when relying solely on open loop logistics without integrating reverse logistics processes.

Environmental Impact: Closed vs. Open Loop Systems

Closed loop logistics significantly reduces environmental impact by enabling the reuse, recycling, and remanufacturing of materials, which minimizes waste and lowers carbon emissions compared to open loop systems. Open loop logistics often leads to increased landfill waste and higher resource consumption since products are discarded after use instead of being reintegrated into the supply chain. Emphasizing closed loop logistics supports sustainable supply chain management and contributes to achieving circular economy goals.

Cost Efficiency Comparison in Logistics Loops

Closed loop logistics often outperforms open loop systems in cost efficiency by reducing waste and enabling reuse of materials throughout the supply chain. By integrating reverse logistics and product lifecycle management, closed loop models lower overall transportation and disposal expenses, leading to significant savings. Optimizing Your logistics with a closed loop approach can maximize resource utilization and minimize operational costs compared to traditional open loop frameworks.

Technological Innovations in Closed and Open Loop Logistics

Technological innovations in closed loop logistics leverage advanced tracking systems, IoT devices, and AI-driven analytics to enhance product lifecycle management and optimize reverse logistics processes. Open loop logistics integrate real-time data sharing platforms and blockchain technology to improve transparency and coordination among multiple independent stakeholders across the supply chain. Your business can harness these technologies to increase efficiency, reduce costs, and promote sustainability in both closed and open loop logistics systems.

Future Trends in Logistics Loop Systems

Future trends in logistics loop systems emphasize the integration of closed loop logistics to enhance sustainability by maximizing resource reuse and minimizing waste. Advanced technologies like IoT, AI, and blockchain are driving more efficient tracking, real-time data analytics, and automated returns processing within closed loop frameworks. You can expect increased adoption of circular economy principles, where open loop logistics gradually transitions to more regenerative, closed loop models to reduce environmental impact and operational costs.

closed loop vs open loop logistics Infographic

libmatt.com

libmatt.com