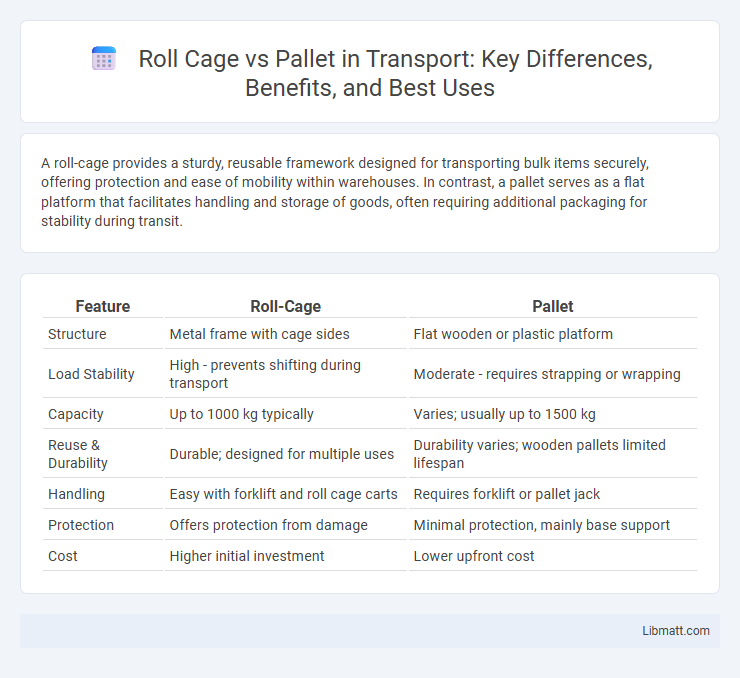

A roll-cage provides a sturdy, reusable framework designed for transporting bulk items securely, offering protection and ease of mobility within warehouses. In contrast, a pallet serves as a flat platform that facilitates handling and storage of goods, often requiring additional packaging for stability during transit.

Table of Comparison

| Feature | Roll-Cage | Pallet |

|---|---|---|

| Structure | Metal frame with cage sides | Flat wooden or plastic platform |

| Load Stability | High - prevents shifting during transport | Moderate - requires strapping or wrapping |

| Capacity | Up to 1000 kg typically | Varies; usually up to 1500 kg |

| Reuse & Durability | Durable; designed for multiple uses | Durability varies; wooden pallets limited lifespan |

| Handling | Easy with forklift and roll cage carts | Requires forklift or pallet jack |

| Protection | Offers protection from damage | Minimal protection, mainly base support |

| Cost | Higher initial investment | Lower upfront cost |

Introduction to Roll-Cages and Pallets

Roll-cages are wheeled metal containers designed for secure and efficient transport of goods within warehouses and retail environments, providing mobility and protection. Pallets are flat transport structures, typically made of wood or plastic, used to support and stabilize goods during shipping and storage through forklifts or pallet jacks. Both roll-cages and pallets enhance material handling by optimizing space utilization and improving logistics efficiency.

Overview of Material Handling Solutions

Roll-cages provide secure, enclosed transport for goods, reducing damage and improving stackability, while pallets offer a flat, sturdy base essential for forklift and pallet jack handling across warehouses. Roll-cages are typically made of metal frames with mesh panels, enhancing visibility and ventilation, whereas pallets are commonly constructed from wood, plastic, or metal to support heavy loads. Selecting between roll-cage and pallet depends on product protection requirements, storage space efficiency, and handling equipment compatibility.

Structural Design: Roll-Cage vs Pallet

Roll-cages feature a reinforced steel frame designed to provide maximum protection and structural integrity during transport and storage, while pallets typically consist of flat, wooden or plastic platforms engineered for stability and load distribution. The roll-cage's vertical and horizontal bars enhance load containment and prevent shifting, unlike pallets which rely on the stacking ability without inherent side protection. When choosing between the two, your decision should consider whether structural strength and item security or simple base support and ease of handling align better with operational needs.

Key Applications and Use Cases

Roll-cages are primarily used in retail, distribution centers, and logistics for transporting goods securely while enabling easy access and mobility. Pallets are fundamental in manufacturing, warehousing, and shipping, offering a stable base for stacking, storing, and moving heavy or bulk items with forklifts or pallet jacks. Both solutions optimize supply chain efficiency but serve distinct roles: roll-cages for secure, organized transport of smaller or loose items, pallets for handling larger, bulk loads.

Load Capacity and Stability Comparison

Roll cages offer higher load capacity and enhanced stability compared to pallets, supporting weights typically up to 1,000 kg or more while securely containing items during transport. Pallets generally have a lower load capacity, ranging from 500 to 1,200 kg depending on material and design, but lack built-in containment, risking load shifting. Choosing a roll cage ensures greater safety and stability for your heavy or delicate goods during handling and storage operations.

Space Efficiency and Storage Optimization

Roll-cages maximize space efficiency by providing stacked, vertical storage options that significantly reduce floor footprint compared to flat pallets. Their open and cage-like design allows for easy visibility and access, enabling better organization and optimized storage density in warehouses. Pallets, while suitable for bulk stacking, often require additional handling equipment and result in less flexible storage arrangements, limiting space optimization in tight or high-density environments.

Handling, Mobility, and Ergonomics

Roll-cages offer superior mobility with their sturdy wheels and swivel casters, enabling smoother maneuvering in tight spaces compared to static pallets. Their enclosed structure enhances safe handling by securely containing goods, reducing the risk of product damage or spillage during transport. Ergonomically, roll-cages minimize manual lifting and bending by allowing easy loading and unloading at waist height, improving worker comfort and reducing injury risk.

Durability and Maintenance Requirements

Roll-cages offer superior durability with reinforced steel frames designed to withstand heavy loads and frequent handling, reducing the risk of deformation and damage over time. Pallets, typically made from wood or plastic, may require more frequent maintenance due to wear, splintering, or exposure to environmental factors. Maintenance for roll-cages involves periodic inspections and repairs of welds and casters, whereas pallets often need regular replacement and treatment to prevent rot or infestation.

Cost Analysis: Roll-Cage vs Pallet

Roll-cages typically incur higher initial costs compared to pallets due to their durable metal construction and design for reusable transport and storage within industries such as retail and logistics. Pallets, often made from wood or plastic, offer a more cost-effective option, especially when considering single-use or bulk shipments, with lower purchase and maintenance expenses. Evaluating the total cost of ownership requires factoring in lifespan, repair, and operational efficiency, where roll-cages excel in long-term savings despite upfront investment, while pallets provide affordability and flexibility for diverse shipping needs.

Choosing the Right Solution for Your Business

Selecting between roll-cages and pallets depends on your business's specific logistics and storage needs. Roll-cages offer enhanced security and mobility for fragile or high-value items, while pallets provide versatility and compatibility with standard forklifts for bulk or heavy goods. Evaluating factors like product type, handling frequency, and warehouse space will help you determine the optimal solution for efficient and safe material handling.

roll-cage vs pallet Infographic

libmatt.com

libmatt.com