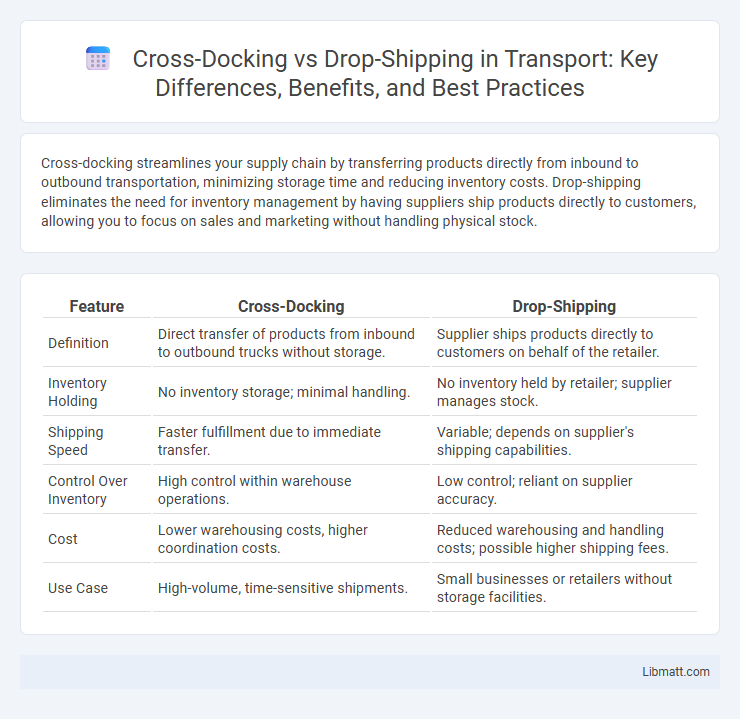

Cross-docking streamlines your supply chain by transferring products directly from inbound to outbound transportation, minimizing storage time and reducing inventory costs. Drop-shipping eliminates the need for inventory management by having suppliers ship products directly to customers, allowing you to focus on sales and marketing without handling physical stock.

Table of Comparison

| Feature | Cross-Docking | Drop-Shipping |

|---|---|---|

| Definition | Direct transfer of products from inbound to outbound trucks without storage. | Supplier ships products directly to customers on behalf of the retailer. |

| Inventory Holding | No inventory storage; minimal handling. | No inventory held by retailer; supplier manages stock. |

| Shipping Speed | Faster fulfillment due to immediate transfer. | Variable; depends on supplier's shipping capabilities. |

| Control Over Inventory | High control within warehouse operations. | Low control; reliant on supplier accuracy. |

| Cost | Lower warehousing costs, higher coordination costs. | Reduced warehousing and handling costs; possible higher shipping fees. |

| Use Case | High-volume, time-sensitive shipments. | Small businesses or retailers without storage facilities. |

Introduction to Cross-Docking and Drop-Shipping

Cross-docking is a logistics strategy where products are directly transferred from inbound to outbound transportation with minimal or no storage time, optimizing inventory flow and reducing handling costs. Drop-shipping involves retailers selling products without holding inventory, with suppliers shipping items directly to customers, minimizing upfront investment and warehousing expenses. Both methods improve supply chain efficiency but differ significantly in inventory management and fulfillment processes.

How Cross-Docking Works

Cross-docking streamlines supply chain operations by receiving products from suppliers and immediately transferring them to outbound trucks without long-term storage, reducing inventory costs and delivery times. This method relies on precise coordination and real-time data to ensure efficient handling and quick turnaround in distribution centers. Your business benefits from faster order fulfillment and reduced warehousing expenses by implementing effective cross-docking strategies.

How Drop-Shipping Works

Drop-shipping operates by allowing retailers to sell products without holding inventory; when a customer places an order, the retailer forwards the purchase details to a third-party supplier who ships the item directly to the customer. This method reduces inventory costs and minimizes warehousing needs since products move straight from supplier to end-user. The retailer earns by marking up the supplier's price, handling sales and customer service while relying on suppliers for inventory management and shipping logistics.

Key Differences Between Cross-Docking and Drop-Shipping

Cross-docking involves transferring products directly from inbound to outbound transportation with minimal storage, optimizing warehouse efficiency and reducing handling costs. Drop-shipping eliminates the need for inventory management by having suppliers ship products directly to customers, which lowers upfront investment and inventory risks. Your choice between cross-docking and drop-shipping depends on factors like control over inventory, delivery speed, and cost management within your supply chain strategy.

Advantages of Cross-Docking

Cross-docking significantly reduces inventory holding costs by minimizing storage time and enabling faster turnover of goods. This logistics strategy enhances supply chain efficiency, leading to shorter delivery times and improved customer satisfaction. Your business benefits from streamlined operations and lower handling expenses when using cross-docking instead of traditional warehousing or drop-shipping.

Advantages of Drop-Shipping

Drop-shipping offers significant advantages such as reduced inventory costs and minimized warehousing needs, enabling retailers to operate with lower upfront investment. It provides scalability and flexibility by allowing sellers to quickly add or remove products without managing stock directly. This model also speeds up order fulfillment by shipping products directly from suppliers to customers, enhancing overall efficiency in the supply chain.

Challenges and Limitations of Both Models

Cross-docking faces challenges such as requiring precise timing and coordination to minimize storage time, high dependency on reliable supply chain partners, and limited flexibility in handling unexpected demand fluctuations. Drop-shipping struggles with lack of control over inventory quality and shipping times, potential issues with supplier reliability, and higher risk of customer dissatisfaction due to delayed or incorrect orders. Your choice between these models should consider these limitations alongside your business priorities for speed, control, and customer experience.

When to Choose Cross-Docking

Choose cross-docking when rapid inventory turnover and reduced storage costs are critical for maintaining supply chain efficiency. It is ideal for high-demand products and perishable goods that require minimal handling and fast delivery from suppliers to customers. Cross-docking optimizes warehouse space and transportation routes, resulting in quicker order fulfillment compared to drop-shipping.

When to Choose Drop-Shipping

Drop-shipping is ideal for businesses with limited upfront inventory investment and those aiming to test new products without warehouse risks. It suits e-commerce stores seeking to save on storage costs while expanding product variety quickly. This method helps businesses avoid inventory management complexities and focus on marketing and sales efforts.

Future Trends in Logistics: Cross-Docking vs Drop-Shipping

Future trends in logistics indicate that cross-docking will enhance supply chain efficiency by reducing storage times and streamlining inventory management. Drop-shipping continues to grow with e-commerce expansion, offering retailers the ability to sell a wide range of products without holding stock, thus minimizing capital investment. Your choice between cross-docking and drop-shipping will depend on factors like inventory control, delivery speed, and customer experience preferences in an evolving digital marketplace.

cross-docking vs drop-shipping Infographic

libmatt.com

libmatt.com