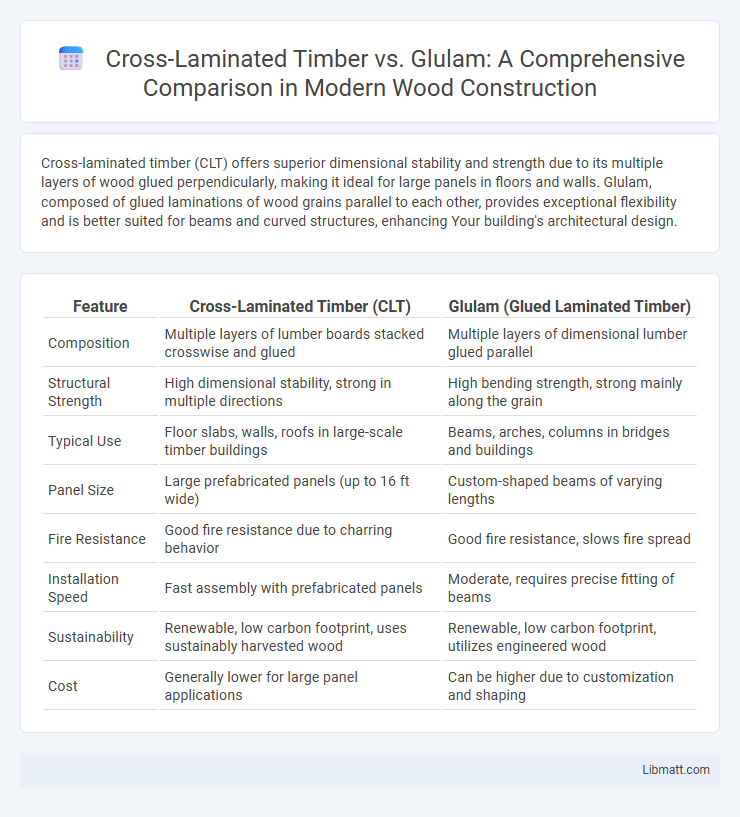

Cross-laminated timber (CLT) offers superior dimensional stability and strength due to its multiple layers of wood glued perpendicularly, making it ideal for large panels in floors and walls. Glulam, composed of glued laminations of wood grains parallel to each other, provides exceptional flexibility and is better suited for beams and curved structures, enhancing Your building's architectural design.

Table of Comparison

| Feature | Cross-Laminated Timber (CLT) | Glulam (Glued Laminated Timber) |

|---|---|---|

| Composition | Multiple layers of lumber boards stacked crosswise and glued | Multiple layers of dimensional lumber glued parallel |

| Structural Strength | High dimensional stability, strong in multiple directions | High bending strength, strong mainly along the grain |

| Typical Use | Floor slabs, walls, roofs in large-scale timber buildings | Beams, arches, columns in bridges and buildings |

| Panel Size | Large prefabricated panels (up to 16 ft wide) | Custom-shaped beams of varying lengths |

| Fire Resistance | Good fire resistance due to charring behavior | Good fire resistance, slows fire spread |

| Installation Speed | Fast assembly with prefabricated panels | Moderate, requires precise fitting of beams |

| Sustainability | Renewable, low carbon footprint, uses sustainably harvested wood | Renewable, low carbon footprint, utilizes engineered wood |

| Cost | Generally lower for large panel applications | Can be higher due to customization and shaping |

Introduction to Engineered Wood: CLT vs Glulam

Engineered wood products like Cross-Laminated Timber (CLT) and Glulam offer advanced structural solutions with superior strength and sustainability. CLT consists of multiple layers of lumber boards stacked crosswise and bonded, providing dimensional stability and high rigidity suited for walls and floors. Glulam features glued layers of timber aligned in the same direction, ideal for beams and arches requiring high load-bearing capacity and design flexibility.

Material Composition and Manufacturing Processes

Cross-laminated timber (CLT) consists of multiple layers of solid-sawn lumber stacked crosswise and glued to form large panels, enhancing dimensional stability and strength. Glulam (glued laminated timber) is made by bonding several layers of dimensional lumber with adhesives, oriented parallel to create long, strong beams. Understanding these distinct manufacturing methods helps you select the optimal engineered wood product for your construction needs based on performance and application.

Structural Performance: Strength and Stability

Cross-laminated timber (CLT) offers superior strength and dimensional stability due to its orthogonal layering, which resists bending and shear forces effectively across multiple directions. Glulam, composed of parallel-laminated wood layers bonded with durable adhesives, provides exceptional load-bearing capacity along the grain, making it ideal for long spans and heavy loads. Both materials exhibit high structural performance, but CLT excels in distributing stresses uniformly, while glulam delivers concentrated strength optimized for beams and columns.

Applications in Modern Construction

Cross-laminated timber (CLT) excels in creating large, prefabricated panels ideal for floors, walls, and roofs in high-rise residential and commercial buildings, providing strength and stability with efficient installation. Glulam, composed of layered wood laminations, is favored for long-span structural elements like beams, arches, and columns, offering design flexibility and aesthetic appeal in architectural projects. Your choice between CLT and glulam depends on specific structural requirements, architectural goals, and the desired balance between load-bearing capacity and visual impact.

Fire Resistance and Safety Aspects

Cross-laminated timber (CLT) demonstrates superior fire resistance compared to glulam due to its layered structure, which chars on the surface and slows combustion, providing enhanced structural integrity during a fire. Glulam beams, while strong and durable, tend to have less predictable fire behavior as their solid laminated layers can ignite more quickly and burn through faster. Building codes increasingly recognize CLT's safety advantages, promoting its use in fire-resistant construction.

Sustainability and Environmental Impact

Cross-laminated timber (CLT) and glulam both offer sustainable alternatives to traditional building materials by utilizing renewable wood resources, significantly reducing carbon footprints compared to steel or concrete. CLT panels provide enhanced carbon sequestration due to their large volume of mass timber layers, while glulam's layered design minimizes waste by allowing the use of smaller, fast-growing timber sections. Both materials contribute to sustainable construction, but CLT often has a slight edge in embodied energy savings and thermal performance, promoting long-term environmental benefits.

Cost Considerations and Economic Viability

Cross-laminated timber (CLT) typically incurs higher initial material costs compared to glulam due to advanced manufacturing processes and panel customization, but offers substantial labor savings through faster installation and reduced waste on-site. Glulam beams, while less expensive upfront, may require more intensive on-site adjustments and connection detailing, increasing labor and time expenses. Assessing economic viability involves balancing CLT's efficient prefabrication benefits against glulam's lower material cost, considering project scale, design complexity, and regional availability.

Design Flexibility and Architectural Aesthetics

Cross-laminated timber (CLT) offers greater design flexibility through its large, prefabricated panels that enable expansive, open floor plans and complex geometric shapes, ideal for modern architectural aesthetics. Glulam beams provide versatile structural support with customizable curvature and lengths, allowing architects to create elegant, exposed timber elements that enhance visual warmth and texture. Both materials contribute to sustainable design but CLT is favored for flat surfaces and wall applications, while glulam excels in beam spans and intricate structural forms.

Installation, Logistics, and Build Speed

Cross-laminated timber (CLT) offers faster installation and simplified logistics due to its large, pre-fabricated panels that cover substantial floor or wall areas quickly, minimizing on-site labor. Glulam beams, while versatile and strong, often require more precise handling and assembly during installation, potentially extending build time. Your choice between CLT and glulam will significantly impact project scheduling and transportation efficiency, with CLT favoring faster build speed and streamlined logistics.

Choosing Between CLT and Glulam: Key Factors

Choosing between Cross-laminated Timber (CLT) and Glulam depends on project scale, structural requirements, and design flexibility. CLT offers superior dimensional stability and is ideal for large-scale panels and floor systems, while Glulam provides greater versatility for beams, columns, and curved shapes requiring high strength. Understanding your building's load demands and architectural goals ensures the best choice for sustainable and efficient timber construction.

Cross-laminated timber vs glulam Infographic

libmatt.com

libmatt.com