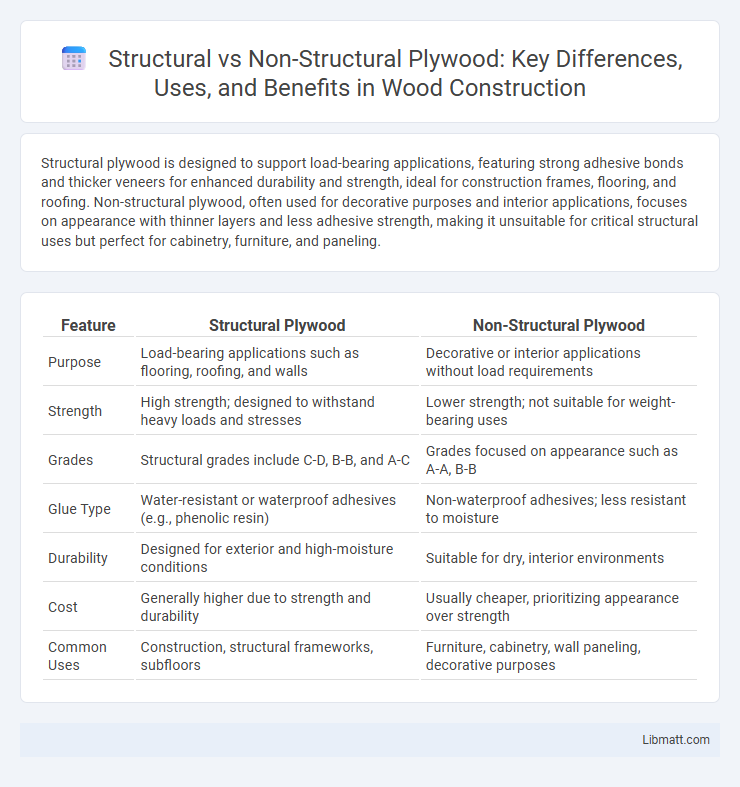

Structural plywood is designed to support load-bearing applications, featuring strong adhesive bonds and thicker veneers for enhanced durability and strength, ideal for construction frames, flooring, and roofing. Non-structural plywood, often used for decorative purposes and interior applications, focuses on appearance with thinner layers and less adhesive strength, making it unsuitable for critical structural uses but perfect for cabinetry, furniture, and paneling.

Table of Comparison

| Feature | Structural Plywood | Non-Structural Plywood |

|---|---|---|

| Purpose | Load-bearing applications such as flooring, roofing, and walls | Decorative or interior applications without load requirements |

| Strength | High strength; designed to withstand heavy loads and stresses | Lower strength; not suitable for weight-bearing uses |

| Grades | Structural grades include C-D, B-B, and A-C | Grades focused on appearance such as A-A, B-B |

| Glue Type | Water-resistant or waterproof adhesives (e.g., phenolic resin) | Non-waterproof adhesives; less resistant to moisture |

| Durability | Designed for exterior and high-moisture conditions | Suitable for dry, interior environments |

| Cost | Generally higher due to strength and durability | Usually cheaper, prioritizing appearance over strength |

| Common Uses | Construction, structural frameworks, subfloors | Furniture, cabinetry, wall paneling, decorative purposes |

Introduction to Plywood Types

Structural plywood consists of layers bonded with strong adhesives designed to withstand heavy loads and provide stability in construction applications, making it suitable for flooring, roofing, and wall sheathing. Non-structural plywood features lower-grade veneers intended for decorative purposes or light-duty uses such as furniture backing or interior paneling, where strength is not a primary concern. Understanding the specific grades, such as APA-rated structural plywood versus flexible, lightweight non-structural types, helps ensure the correct application for durability and safety.

Defining Structural Plywood

Structural plywood is engineered to meet specific strength and durability standards, making it suitable for load-bearing applications in construction such as flooring, roofing, and wall sheathing. It is typically graded and tested according to industry standards like PS 1-09 or PS 2-18, ensuring high performance under stress. In contrast, non-structural plywood is designed primarily for aesthetic or decorative purposes without the rigorous strength requirements.

Understanding Non-Structural Plywood

Non-structural plywood is designed primarily for aesthetic applications and light-duty use, lacking the strength and durability required for load-bearing structures. It typically features fewer layers, lower-grade veneers, and can be prone to warping or delamination under heavy stress or moisture exposure. This type of plywood is ideal for interior projects like furniture, cabinetry, and decorative paneling where structural integrity is not critical.

Key Differences: Structural vs Non-Structural

Structural plywood is engineered to meet specific strength and durability standards, making it suitable for load-bearing applications such as flooring, roofing, and wall sheathing. Non-structural plywood lacks the same level of strength and is primarily used for decorative purposes, furniture, or interior paneling where load-bearing capacity is not required. The key difference lies in their graded performance characteristics: structural plywood undergoes rigorous testing to ensure resistance to bending, compression, and shear forces, while non-structural plywood prioritizes appearance and cost-effectiveness over mechanical performance.

Applications of Structural Plywood

Structural plywood is engineered for load-bearing applications, making it ideal for construction tasks such as wall sheathing, flooring, roofing, and subflooring where strength and durability are critical. It meets specific building codes and standards, ensuring safety and performance in frameworks, bridges, and other heavy-duty architectural projects. Your choice of structural plywood guarantees reliable support and resistance to bending and shear forces in demanding environments.

Uses of Non-Structural Plywood

Non-structural plywood is primarily used in applications where strength and load-bearing capacity are not critical, such as furniture, cabinetry, interior paneling, and decorative projects. It offers a smooth surface finish ideal for painting and veneering, making it popular for aesthetic purposes in residential and commercial interiors. This type of plywood is not suitable for exterior use or structural support due to its lower durability and resistance to moisture.

Strength and Durability Comparison

Structural plywood is engineered with multiple cross-laminated layers, providing superior strength and durability suitable for load-bearing applications such as flooring, roofing, and wall sheathing. Non-structural plywood, composed of fewer or less rigorously bonded layers, offers less resistance to stress and is typically used for decorative or light-duty purposes where high strength is not critical. The enhanced adhesion and uniform thickness of structural plywood contribute to its ability to withstand heavier forces and prolonged exposure to environmental factors.

Standards and Certifications

Structural plywood complies with standards such as PS 1-09 and APA's Performance Rated Panel (PRP) certification, ensuring load-bearing capacity, shear strength, and moisture resistance for construction use. Non-structural plywood typically meets standards like ASTM D3043 but lacks the rigorous testing for structural integrity and durability under stress. Certifications such as HUD/FHA approval and CARB compliance emphasize environmental safety and indoor air quality, which are more common in non-structural grades.

Cost Factors for Each Type

Structural plywood typically incurs higher costs due to its enhanced durability, load-bearing capacity, and compliance with building codes, which require more robust manufacturing processes and certifications. Non-structural plywood is generally more affordable as it is designed for aesthetic or interior uses where strength is less critical, involving fewer material and quality specifications. Price variations also depend on factors such as wood species, thickness, adhesive type, and treatment for moisture resistance.

Choosing the Right Plywood for Your Project

Selecting the right plywood for your project depends on understanding the differences between structural and non-structural plywood. Structural plywood, designed for load-bearing applications, offers superior strength and durability, making it ideal for framing, flooring, and roofing. Non-structural plywood, on the other hand, is best suited for decorative or interior uses where strength is less critical, ensuring your project balances performance with cost efficiency.

Structural vs non-structural plywood Infographic

libmatt.com

libmatt.com